A design method of transmission helical gear

A design method, helical gear technology, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve problems such as inaccurate results, no coincidence, limited noise optimization of transmission helical gears, etc., to achieve Reduce repeated revisions, save time, and reduce development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

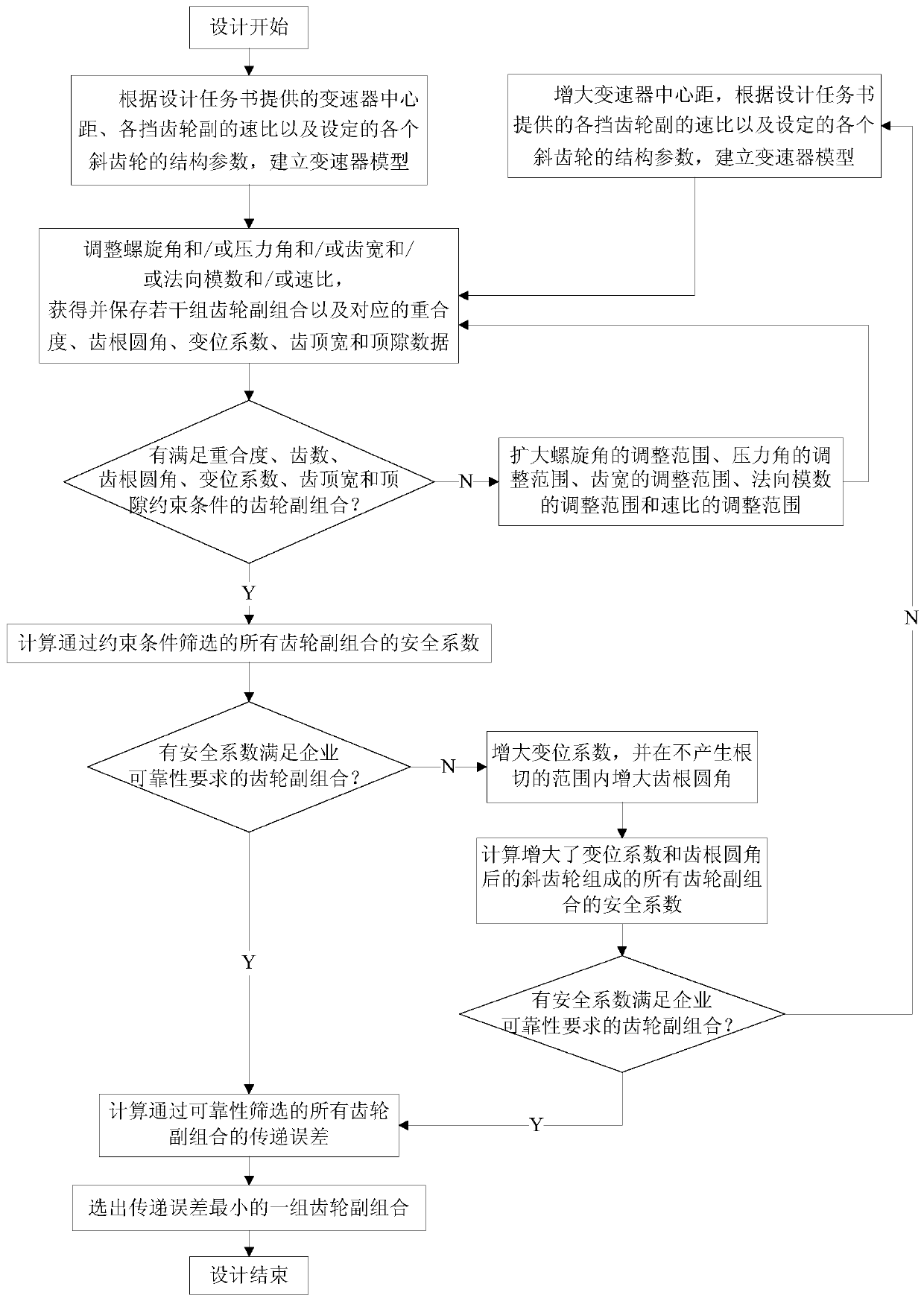

[0032] Such as figure 1 The design method of the transmission helical gear is shown, including:

[0033] The first step, according to the center distance of the transmission provided in the design task book, the speed ratio of each gear pair and the set structural parameters of each helical gear (that is, helix angle, pressure angle, normal modulus, number of teeth, tooth width, variable coefficient, backlash, tooth profile chamfer, addendum chamfer, machining allowance), use the Romax software to establish a transmission model, and obtain the coincidence degree data, dedendum fillet data of each gear pair from the transmission model, Variation coefficient data, addendum width data, and top clearance (or bottom clearance) data; among them, the helix angle of each helical gear is set to 30°, the pressure angle to 20°, the variation coefficient to 0, and the backlash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com