Device capable of automatically converting between wire barrel type polar plate and barb barrel type polar plate

A technology of automatic conversion and wire awning tube, which is applied in the field of electrostatic dust removal, can solve the problem of poor dust removal effect of fine particles, and achieve the effect of meeting the needs of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

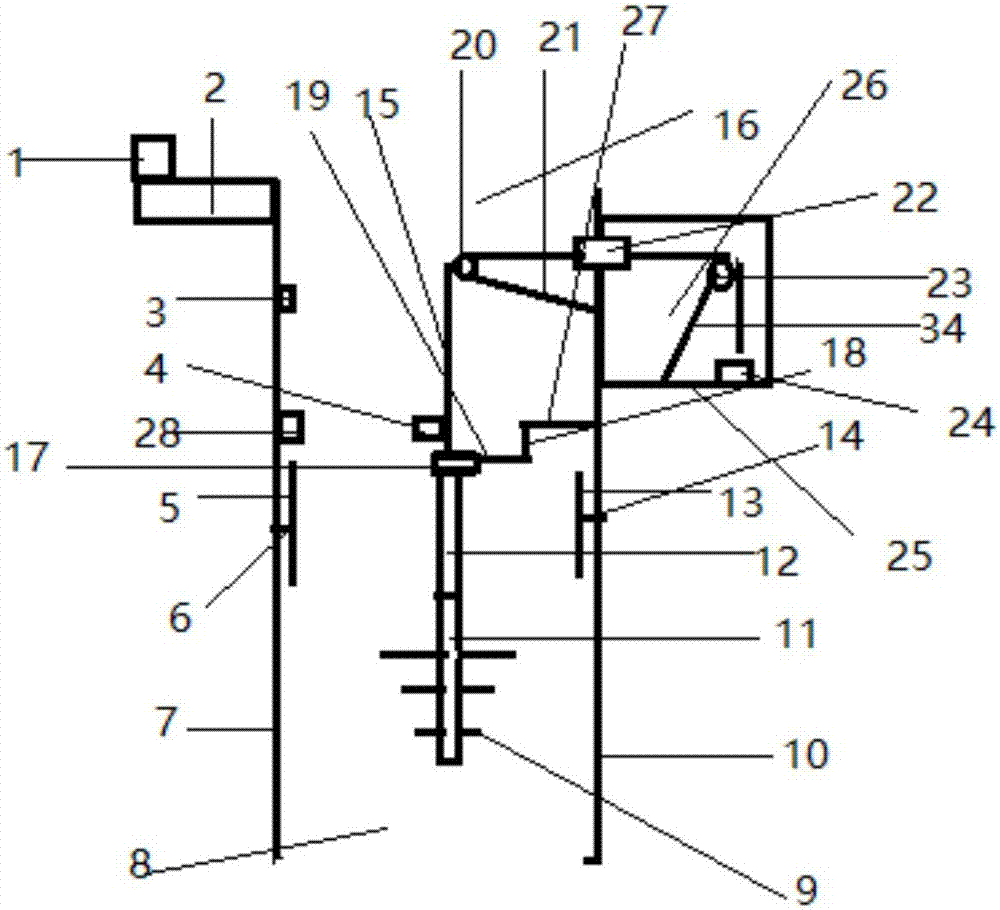

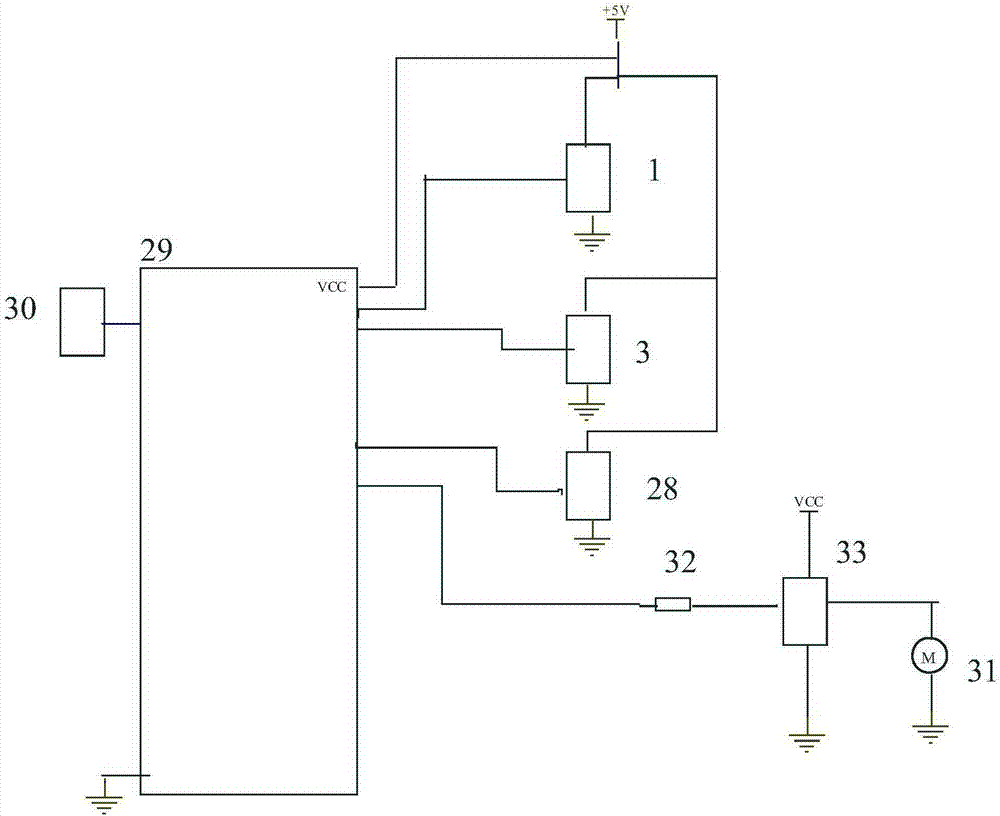

[0012] exist figure 1 Among them, the particle sensor 1 is connected to the left side wall 7 of the flue through the sampling flue 2, the upper magnetic sensitive sensor 3 is connected to the left side wall 7 of the flue, the lower magnetic sensitive sensor 28 is connected to the left side wall 7 of the flue, and the cylindrical The left side wall 5 of the dust plate is connected with the left side wall 7 of the flue through the left fixed rod 6, the burr 9 is connected with the thorn discharge electrode 11, the burr discharge electrode 11 is connected with the linear discharge electrode 12, and the traction rope 15 is connected with the discharge electrode 11. The linear discharge electrodes 12 are connected, the discharge electrode sliding ring 17 is connected with the vertical support rod 18 through the front half horizontal support rod 19, the vertical support rod 18 is connected with the right side wall 10 of the flue through the rear half horizontal support rod 27, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com