Automatic receiver-transmitter cabinet for material pneumatic conveyor system

A technology of pneumatic conveying and sending and receiving cabinets, which is applied in conveyors, transportation and packaging, etc. It can solve the problems of low intelligence, low intelligence and poor adaptability at the receiving end, so as to meet the requirements of batch diversification and intelligence. The effect of high degree and meeting precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with specific embodiments and drawings.

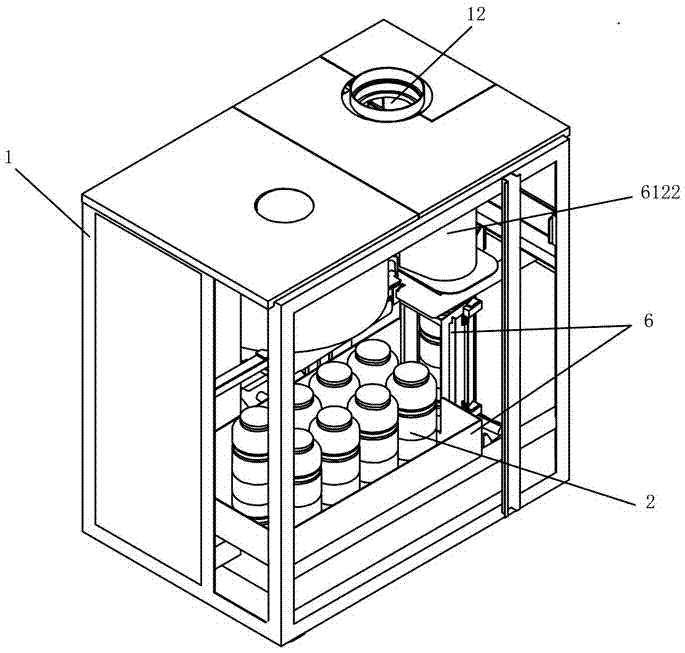

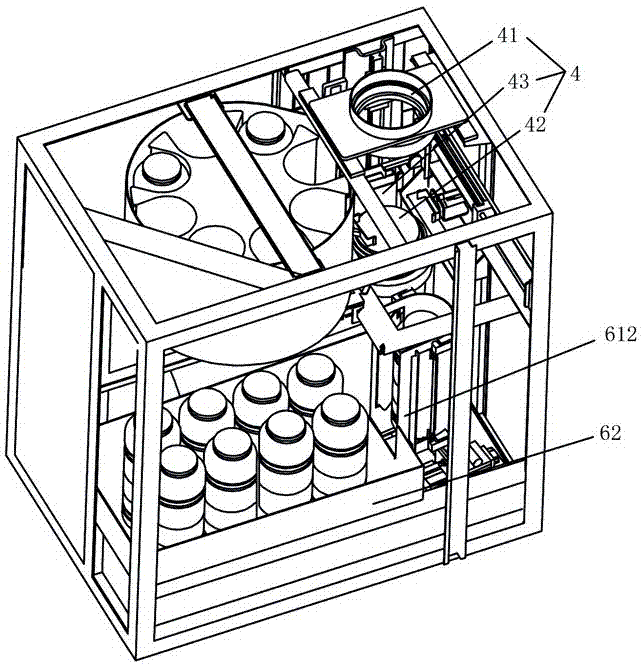

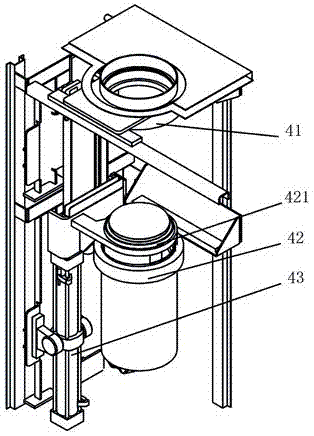

[0036] Such as Figure 1 to Figure 5 As shown, the present invention provides an automatic receiving and dispatching cabinet for a pneumatic material conveying system, comprising a cabinet body 1, a bottle opening and receiving and dispatching ports 12 are provided on the top surface of the cabinet body 1, and the top surface of the cabinet body 1 is also provided There is an intelligent control button area, and an electronic control device is arranged on the side of the cabinet 1. The cabinet 1 is provided with a matching receiving and storing device 6 and a receiving and sending pipeline device 4, the receiving and storing pipeline device 4 is connected with the external pneumatic conveying pipeline through the receiving and sending port 12 for receiving the transmitted sample bottle 2 (the receiving and sending pipeline device 4 The sending of sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com