A kind of tertiary amine derived from ansa-type ferrocene and its preparation method and application

A technology of ferrocene and diacetyl ferrocene is applied in the preparation of organic compounds, the preparation of amino compounds, chemical instruments and methods, etc., and can solve the problems of poor stability, expensive preparation, moisture and air sensitivity, and the like, Achieve mild reaction conditions, high catalytic activity, and good chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

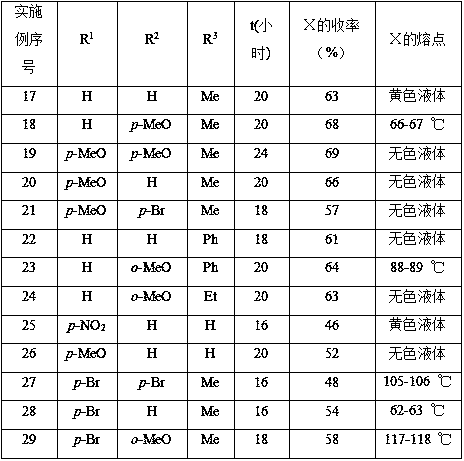

Examples

Embodiment 1

[0043] Example 1: Preparation of 1,1'-(1-methyl-3-oxygen-1,3-allyl)ferrocene IV

[0044] In a 250 mL three-necked flask, diacetylferrocene III (10.0 g, 37 mmol) was dissolved in dichloromethane (150 g); dry dimethylamine gas (24.2 g, 0.55 mol), adding AlCl in batches 3 (9.8 g, 74 mmol), slowly raised to room temperature and reacted for 30 hours; filtered the insoluble matter, concentrated the filtrate and separated it by silica gel (GF254, the same below) column chromatography (the eluent was petroleum ether and ethyl acetate, and the volume ratio was 50 : 1), obtained 6.9 g compound IV, m.p.: 85~86 ℃, yield 74%; 1 H NMR (400 MHz, CDCl 3 ) δ 2.15 (s, 3H), 4.27-4.53 (m, 8H), 6.35 (s,1H). 13 C NMR (100 MHz, CDCl 3 ) δ 26.0, 71.5 (2C), 72.3 (2C), 72.9 (2C), 73.0(2C), 84.7, 86.0, 133.2, 152.5, 197.0.

Embodiment 2

[0045] Example 2: Preparation of 1,1'-(1-methyl-3-oxygen-1,3-propyl)ferrocene V

[0046] In a 25 mL two-necked flask, 1,1'-(1-methyl-3-oxo-1,3-allyl)ferrocene IV (5.04 g, 20 mmol) was dissolved in anhydrous dichloromethane (20 g), add 5% Pd / C (0.1 g), under normal temperature and pressure in H 2 The reaction was carried out in the atmosphere for 8 hours; after the reaction was completed, it was suction filtered, and the obtained dichloromethane organic layer was concentrated and then separated by column chromatography (eluent was petroleum ether and ethyl acetate, the volume ratio was 30: 1), and 4.8 g of compound Ⅴ was obtained. , m.p.: 102~104 ℃, yield 96%; 1 H NMR (400MHz, CDCl 3 ) δ 1.25 (d, J = 6.4 Hz, 3H), 2.60 (dd, J = 2.8, 6.8 Hz, 1H), 3.21-3.27 (m, 2H), 3.97 (s, 1H), 4.08 (s, 1H), 4.33 (d, J = 15.2 Hz, 2H), 4.49 (s,1H), 4.67 (d, J = 14.8 Hz, 2H), 4.90 (s, 2H). 13 C NMR (100 MHz, CDCl 3 ) δ22.70, 39.0, 52.2, 67.6, 68.4 (2C), 68.9 (2C), 69.9, 71.5, 72.3 (2C)...

Embodiment 3

[0047] Example 3: Preparation of 1,1'-(1-methyl-3-hydroxyl-1,3-propyl)ferrocene VI

[0048] Take a 50 mL two-necked flask, dissolve 1,1'-(1-methyl-3-oxo-1,3-propyl)ferrocene V (5.08 g, 20 mmol) in absolute ethanol (20 g) , adding NaBH 4 (0.76 g, 20 mmol) at N 2 The reaction was stirred under the atmosphere and protected from light for 6 hours. After the reaction was complete, the solvent was evaporated, and 5% aqueous sodium carbonate was added, extracted with ethyl acetate, and the resulting organic layer was concentrated and separated by column chromatography (eluent was petroleum ether and ethyl acetate). , with a volume ratio of 8 : 1), 4.7 g of compound VI was prepared, m.p.: 81~83 ℃, yield 95%; 1 H NMR (400 MHz, CDCl 3 ) δ 1.26 (d, J = 6.8 Hz, 3H), 1.98 (t, J = 11.2,12.0 Hz, 1H), 2.36-2.41 (m, 4H), 2.55 (t, J = 6.8, 7.2 Hz, 1H), 4.01-4.15 (m,8H), 4.43 (s, 1H), 4.54 (d, J = 6.8 Hz, 1H). 13 C NMR (100 MHz, CDCl 3 ) δ 20.8, 24.6, 51.6, 65.1, 66.3, 67.1, 67.3, 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com