A kind of preparation method of stable concrete slump control agent

A concrete and slump technology, applied in the field of building materials, can solve the problems that the slump-preserving effect is susceptible to temperature, insufficient slump-preserving effect, and influence, etc., and achieves the effect of excellent slump retention effect and high initial water reduction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

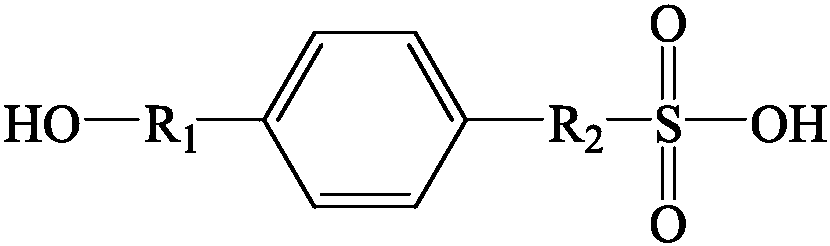

Method used

Image

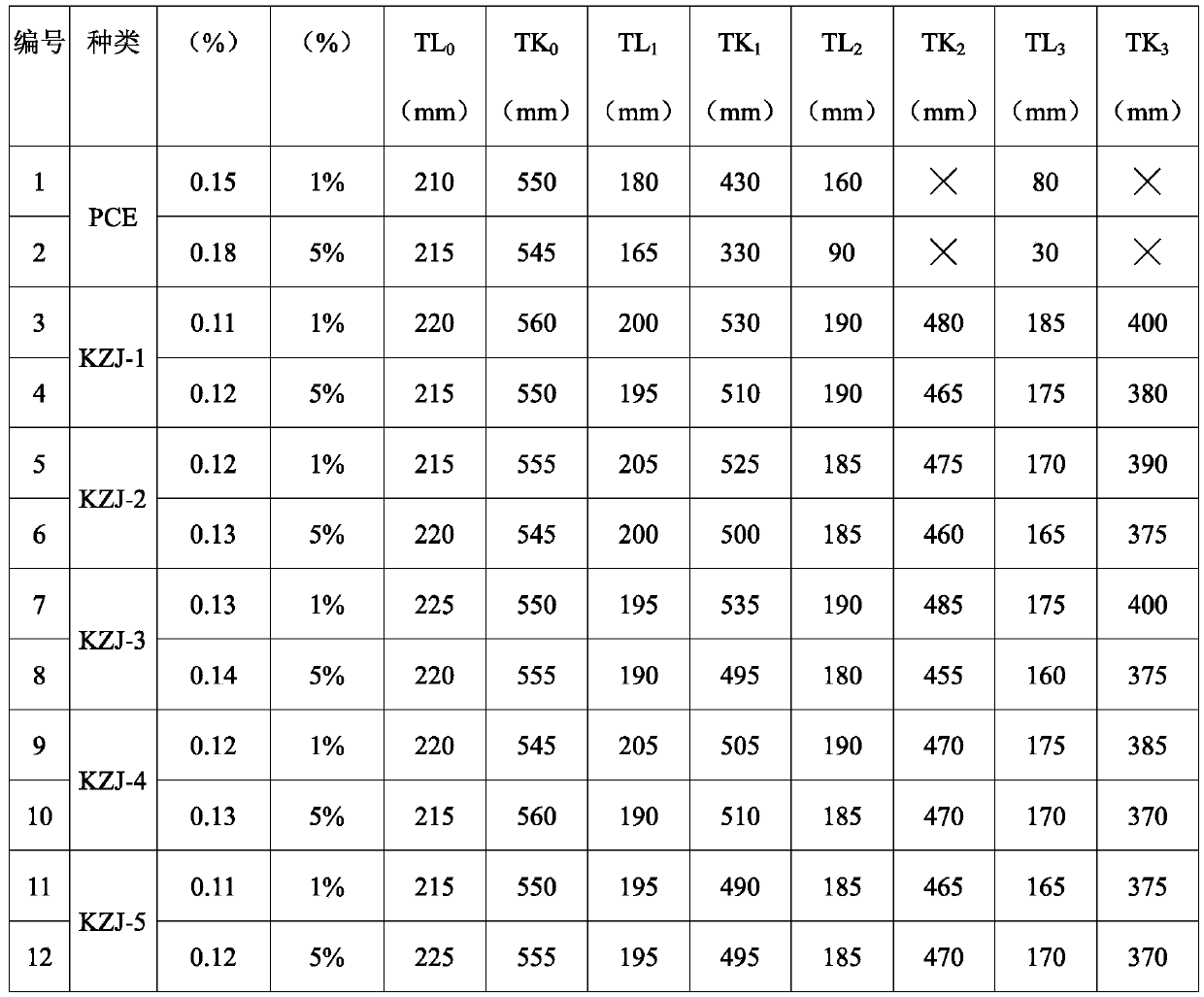

Examples

Embodiment 1

[0026] (1) Mix 240.00g of acrylic acid, 200.00g of p-hydroxybenzenesulfonic acid, and 6.50g of phenothiazine. Under the protection of nitrogen, heat up to 60°C, add 8.23g of p-toluenesulfonic acid, heat up to 110°C, and keep the temperature for 2 hours. During the period, the water is removed by vacuumizing or nitrogen-carrying water, and the reaction is cooled to room temperature after the end of the reaction to obtain the first mixture containing the esterification product and unreacted acrylic acid;

[0027] (2) Mix 20.00 g of the first mixture prepared in step (1), 185.00 g of 4-hydroxybutyl vinyl polyoxyethylene ether with a molecular weight of 2400, and add 120.00 g of water to dissolve it to obtain a comonomer mixture solution;

[0028] (3) Mix the above-mentioned comonomer mixture solution with hydrogen peroxide aqueous solution (wherein, hydrogen peroxide 1.20g, water 20.00g), ascorbic acid aqueous solution (wherein, ascorbic acid 0.40g, water 20.00g), ferrous sulfate...

Embodiment 2

[0031] (1) Mix 247.00g of methacrylic acid, 200.00g of p-hydroxymethylbenzenesulfonic acid, 5.60g of hydroquinone, and 2.00g of phenothiazine. Under the protection of nitrogen, the temperature is raised to 50°C, and 8.20g of mass fraction is added. 98% concentrated sulfuric acid, heat up to 115°C, keep warm for 3 hours, remove water by vacuuming or blowing nitrogen with water, and cool down to room temperature after the reaction to obtain the first product containing esterification products and unreacted methacrylic acid. a mixture;

[0032] (2) Mix 20.00 g of the first mixture prepared in step (1) with 260.00 g of 4-hydroxybutyl vinyl polyoxyethylene ether with a molecular weight of 2400, and add 150.00 g of water to dissolve it to obtain a comonomer mixture solution;

[0033] (3) Mix the above-mentioned comonomer mixture solution with hydrogen peroxide aqueous solution (wherein, hydrogen peroxide 1.10g, water 20.00g), dimple aqueous solution (wherein, dimple 0.70g, water 20...

Embodiment 3

[0036] (1) Mix 156g of acrylic acid, 86g of methacrylic acid, 200.00g of p-hydroxyethylbenzenesulfonic acid, and 4.20g of hydroquinone. Under nitrogen protection, heat up to 60°C, add 6.30g of ethylsulfonic acid, and heat up to 110°C, heat preservation reaction for 2 hours, during which the water was removed by vacuuming or nitrogen with water, and after the reaction was completed, it was lowered to room temperature to obtain the first mixture containing the esterification product and unreacted acrylic acid and methacrylic acid;

[0037] (2) Mix 20.00 g of the first mixture prepared in step (1) with 233.00 g of 4-hydroxybutyl vinyl polyoxyethylene ether with a molecular weight of 2400, and add 150.00 g of water to dissolve it to obtain a comonomer mixture solution;

[0038](3) Mix the above-mentioned comonomer mixture solution with hydrogen peroxide aqueous solution (wherein, hydrogen peroxide 1.30g, water 20.00g), ascorbic acid aqueous solution (wherein, ascorbic acid 0.30g, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com