A kind of preparation method of concrete fluidity stabilizer

A fluidity and concrete technology, applied in the field of building admixtures, can solve the problems of low initial fluidity of concrete, unfavorable production control, and reduced fluidity, and achieve high double bond retention rate, which is beneficial to construction and moderate hydrolysis rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

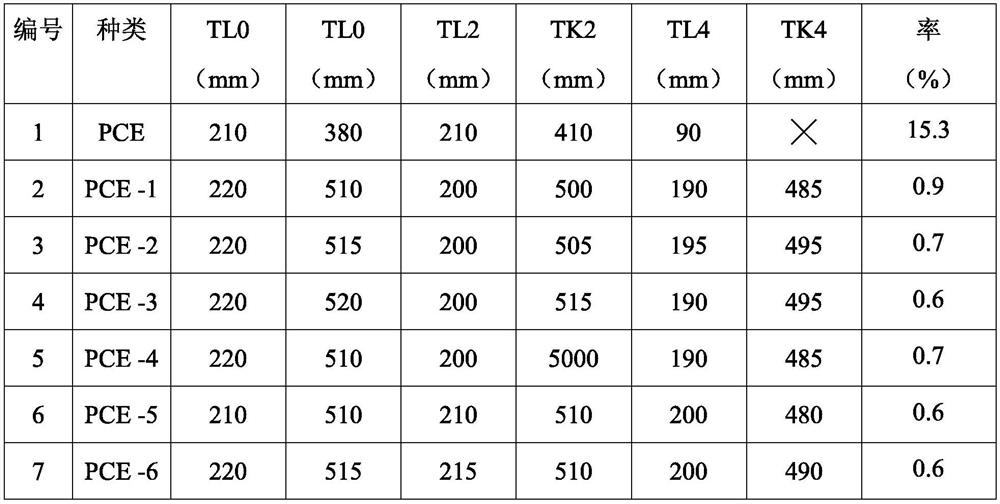

Examples

Embodiment 1

[0023] (1) Esterification: Mix 255.00g maleic anhydride, 80.00g p-hydroxybenzoic acid, 20.00g o-hydroxybenzoic acid, 1.00g hydroquinone and 2.70g phenothiazine, and heat up to 65 ℃, then add 1.00g of periodic acid and 2.00g of dinitrobenzoic acid, heat preservation reaction for 3.0h, during which the water is removed by vacuuming or nitrogen with water, and after the reaction is completed, it is lowered to room temperature, and the product containing esterification and a first mixture of unreacted maleic anhydride;

[0024] (2) Monomer blending: Mix 2.00 g of the first mixture prepared in step (1), 2.80 g of sodium styrene sulfonate, and 100.00 g of APEG with a molecular weight of 2400, and add 70.00 g of water to dissolve it to obtain a copolymer monomer mixture solution;

[0025] (3) Copolymerization reaction: the above-mentioned comonomer mixture solution, hydrogen peroxide aqueous solution (wherein hydrogen peroxide 1.00g, water 20.00g), ascorbic acid aqueous solution (wh...

Embodiment 2

[0028] (1) Esterification reaction: Mix 115.00g acrylic acid, 94.00g methacrylic acid, 45.00g o-hydroxybenzoic acid, 55.00g o-hydroxymethylbenzoic acid, 2.00g hydroquinone and 2.00g diphenylamine, under nitrogen protection 2.00g of dinitrobenzoic acid and 1.00g of ethylenediaminetetraacetic acid were added, and the reaction was kept for 2 hours. During this period, the water was removed by vacuuming or nitrogen with water. After the reaction was completed, the temperature was lowered to room temperature. Obtain the first mixture that contains esterification product and unreacted acrylic acid, methacrylic acid;

[0029] (2) Monomer blending: 4.00 g of the first mixture prepared in step (1), 1.00 g of sodium allyl sulfonate, 2.60 g of sodium vinyl sulfonate and 100.00 g of TPEG with a molecular weight of 2400 were mixed, and 70.00 g of g of water to dissolve it to obtain a comonomer mixture solution;

[0030] (3) Copolymerization reaction: the above-mentioned comonomer mixture ...

Embodiment 3

[0033] (1) Esterification reaction: Mix 108.00g acrylic acid, 232.00g fumaric acid, 50.00g p-hydroxyphenylacetic acid, 50.00g p-hydroxymethylbenzoic acid, 2.00g hydroquinone and 2.00g diphenylamine, under nitrogen protection 2.00g of periodic acid and 0.90g of ethylenediaminetetraacetic acid were added, and the reaction was kept for 1.0h. During this period, the water was removed by vacuuming or nitrogen with water. After the reaction was completed, it was lowered to room temperature to obtain A first mixture containing esterification products and unreacted acrylic acid and fumaric acid;

[0034](2) Monomer blending: Mix 5.00 g of the first mixture prepared in step (1), 2.00 g of sodium styrene sulfonate, 2.20 g of sodium methacrylate sulfonate, and 100.00 g of HPEG with a molecular weight of 2400, and add 70.00 g of water to dissolve it to obtain a comonomer mixture solution;

[0035] (3) Copolymerization reaction: the above-mentioned comonomer mixture solution, azodicyanova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com