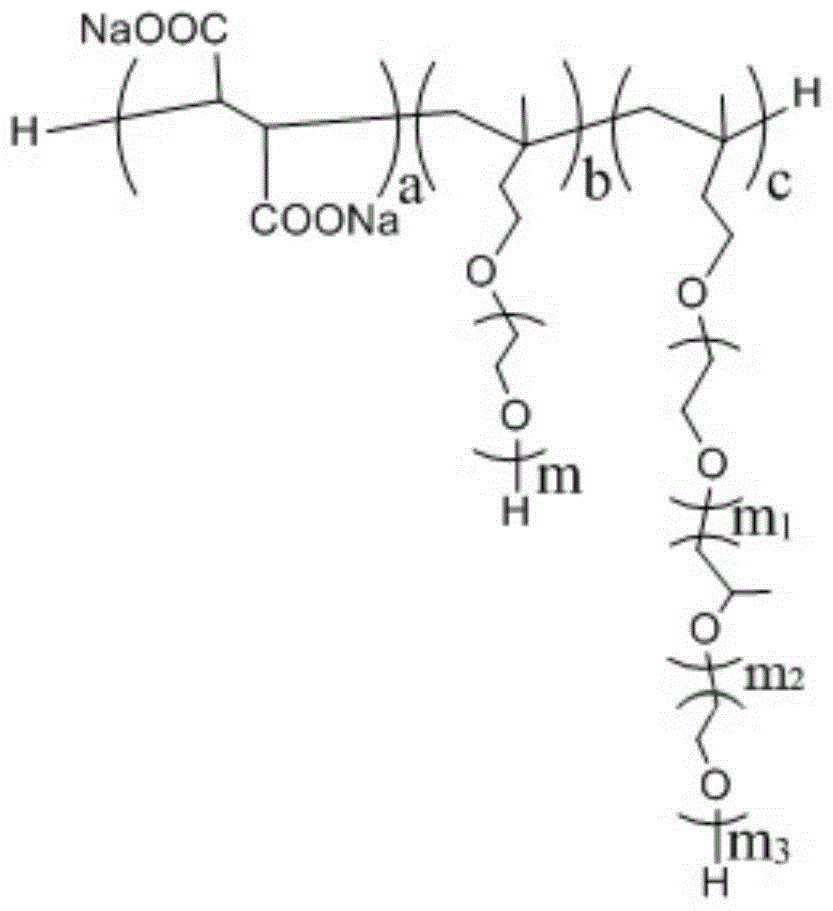

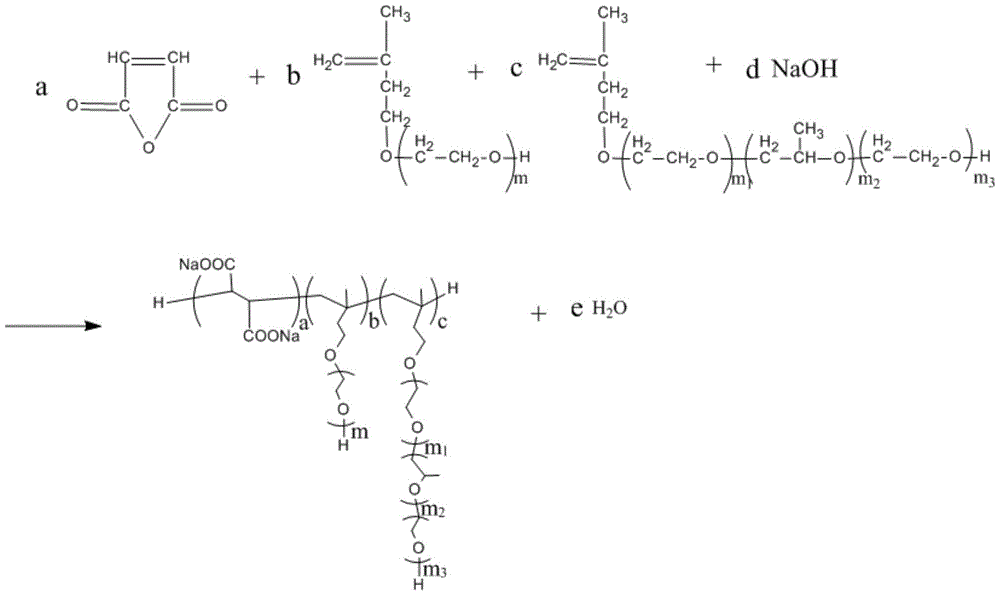

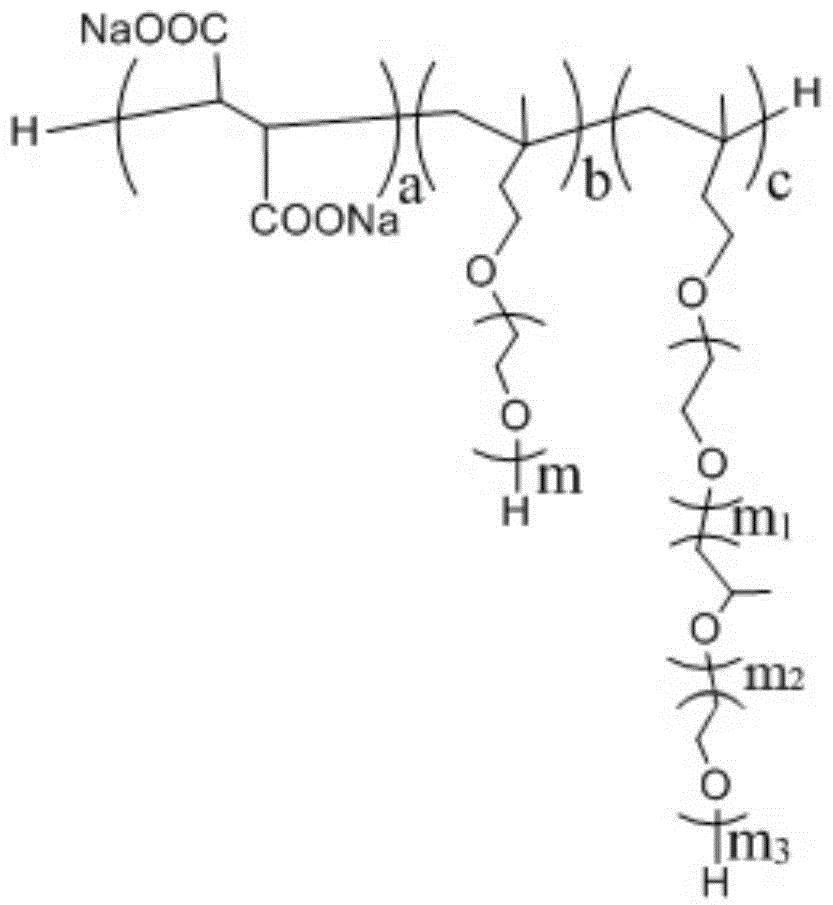

A kind of graft copolymerization high-performance polycarboxylate water-reducer of ternary block macromonomer and its preparation method

A ternary block and macromonomer technology, used in the field of concrete admixtures, can solve the problems of poor slump retention and no slow release properties of water reducers, and achieve excellent slump retention, low air content, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the above-mentioned three-element block macromonomer graft copolymerization high-performance polycarboxylate water reducer, the specific steps are as follows:

[0036] A three-necked flask equipped with a stirrer was placed in a temperature-controlled electric heating mantle, and 155.1 g of isopentenol polyoxyethylene ether with a molecular weight of 2600, 27.4 g of ternary block polyether, 25.2 g of maleic anhydride and 200 g of water were added, Stir evenly and heat up to 75°C; then add 7 g of ammonium persulfate at one time, and simultaneously add dropwise 10.15 g of an aqueous solution of ascorbic acid (which contains 0.15 g of ascorbic acid) and 10.3 g of an aqueous solution of thioglycolic acid (which contains 0.3 g of thioglycolic acid), and after 4 hours After the dropwise addition is completed (the dropping rate is about 0.4ml / min), continue to insulate and mature for 1 hour, add 60g of 30% NaOH solution to neutralize the pH of the syst...

Embodiment 2

[0040] The preparation method of the above-mentioned three-element block macromonomer graft copolymerization high-performance polycarboxylate water reducer, the specific steps are as follows:

[0041] Place the three-necked flask equipped with a stirrer in a temperature-controlled electric heating mantle, add 146g of isopentenol polyoxyethylene ether with a molecular weight of 5500, 36.5g of ternary block polyether, 25.2g of maleic anhydride and 200g of water, and stir evenly , the temperature was raised to 75°C; then 7g of ammonium persulfate was added at one time, and at the same time, 10.15g of an aqueous solution of ascorbic acid (which contained 0.15g of ascorbic acid), and 10.3g of an aqueous solution of thioglycolic acid (which contained 0.3g of thioglycolic acid) were added dropwise, and after 4 hours, the Complete (dropping speed is about 0.4ml / min), continue to heat preservation and aging for 1 hour, add 60g of 30% NaOH solution to neutralize the pH of the system to 6...

Embodiment 3

[0045] The preparation method of the above-mentioned three-element block macromonomer graft copolymerization high-performance polycarboxylate water reducer, the specific steps are as follows:

[0046] Place the three-necked flask equipped with a stirrer in a temperature-controlled electric heating mantle, add 122.6 g of isopentenol polyoxyethylene ether with a molecular weight of 2600, 41.1 g of ternary block polyether, 25.2 g of maleic anhydride and 200 g of water, and stir Evenly, the temperature was raised to 75°C; then 7g of ammonium persulfate was added at one time, and at the same time, 10.15g of an aqueous solution of ascorbic acid (which contained 0.15g of ascorbic acid) and 10.3g of an aqueous solution of thioglycolic acid (which contained 0.3g of thioglycolic acid) were added dropwise. After the addition is completed (the dropping rate is about 0.4ml / min), continue to heat and ripen for 1 hour, add 60g of 30% NaOH solution to neutralize the pH of the system to 6-7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com