Preparation method of powder melamine high-efficiency water reducing agent

A high-efficiency water-reducing agent and melamine technology, applied in the field of preparation of powdered melamine high-efficiency water-reducing agent, can solve problems such as water solubility and stability reduction, loss of performance such as water reducing rate, immature production technology, etc., and achieve air-entraining properties. The effect of low, reduced packaging and transportation costs, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In a three-neck flask equipped with mechanical stirring and a thermometer, add 7.77g of melamine, then add 15.00g of 37% formaldehyde solution, add 30% sodium hydroxide dropwise under stirring to adjust the pH of the solution to 9, control the temperature at 55°C, and react for 60 minutes ; Add 7.15g of sulfamic acid under continuous stirring, then adjust the pH of the solution to 10 with 30% sodium hydroxide, raise the temperature to 80°C, and perform sulfonation for 60 minutes; lower the temperature to 50°C, and adjust the pH of the solution with 30% sulfuric acid =5, react for 40 minutes; filter while hot to obtain liquid melamine superplasticizer.

[0026] Weigh 17.35 g of the liquid melamine superplasticizer prepared above, add 0.10 g of cellobiose, stir to dissolve it completely, concentrate, dry into a solid state, and then pulverize to obtain a powder melamine superplasticizer .

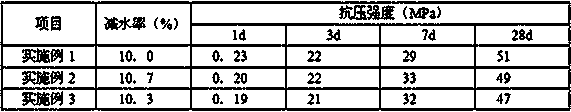

[0027] According to GB8076-2008, the concrete water-reducing rate and compressive...

Embodiment 2

[0029] In a three-necked flask equipped with mechanical stirring and a thermometer, add 7.77g of melamine, then add 16.00g of 37% formaldehyde solution, add 30% sodium hydroxide dropwise under stirring to adjust the pH of the solution to 10, control the temperature at 57°C, and react for 80 minutes ; Add 7.20g of sulfamic acid under continuous stirring, then use 30% sodium hydroxide to adjust the pH of the solution to 11, raise the temperature to 83°C, and perform the sulfonation reaction for 70 minutes; lower the temperature to 53°C, and use 30% sulfuric acid to adjust the pH of the solution =5.5, reacted for 50 minutes; filtered while hot to obtain liquid melamine superplasticizer.

[0030] Weigh 34.7 g of the liquid melamine superplasticizer prepared above, add 0.20 g of cellobiose, stir to dissolve it completely, concentrate, dry into a solid state, and then pulverize to obtain a powder melamine superplasticizer .

[0031] According to GB8076-2008, the concrete water-redu...

Embodiment 3

[0033] In a three-necked flask equipped with mechanical stirring and a thermometer, add 7.77g of melamine, then add 17.50g of 37% formaldehyde solution, add 30% sodium hydroxide dropwise under stirring to adjust the pH of the solution to 12, control the temperature at 60°C, and react for 90 minutes ; Add 7.23g of sulfamic acid under continuous stirring, then use 30% sodium hydroxide to adjust the pH of the solution to 12, raise the temperature to 85°C, and perform the sulfonation reaction for 80 minutes; lower the temperature to 55°C, and use 30% sulfuric acid to adjust the pH of the solution =6, react for 60 minutes; filter while hot to obtain liquid melamine superplasticizer.

[0034] Weigh 23.1 g of melamine superplasticizer, add 0.13 g of sorbitol, stir to dissolve it completely, then concentrate and dry to obtain powdered melamine superplasticizer.

[0035] According to GB8076-2008, the concrete water-reducing rate and compressive strength were tested when the amount of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com