Method for producing cement grinding aid by replacement and sulfonation of tri-isopropanolamine

A technology of triisopropanolamine and cement grinding aid, applied in organic chemistry, sulfonate preparation and other directions, can solve problems such as side reactions and sulfuric acid affecting the reaction process, and achieve low air entrainment, easy product quality, and improved product quality. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

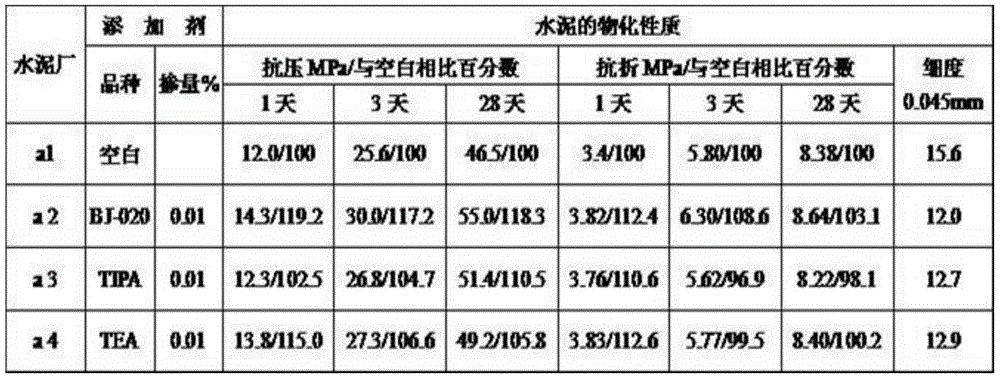

Embodiment 1

[0059] to 1M 3 The reactor was depressurized to -0.09Mpa, and 191kg of triisopropanolamine was pumped into the reactor, and then 490kg of concentrated sulfuric acid was added into the reactor, the stirring speed was set at 30r / min, and the temperature in the reactor was 45°C to 60°C. Simultaneously, the pressure was reduced to 0.09Mpa, and the reaction time was half an hour; the sodium sulfite solution with an effective content of 252kg was pumped into the still, and the stirring speed was adjusted to 30r / min, and the pressure in the still was adjusted to normal pressure, and the temperature in the still was 70 ℃, maintain the reaction conditions for 1.5h; then adjust the reaction kettle to normal temperature and pressure, add an aqueous solution with an effective sodium hydroxide of 240kg, adjust the stirring speed to 10r / min, take a sample and analyze the pH value of 11.0 after 20 minutes, then the reaction is over , get product BJ-020 of the present invention.

[0060] The...

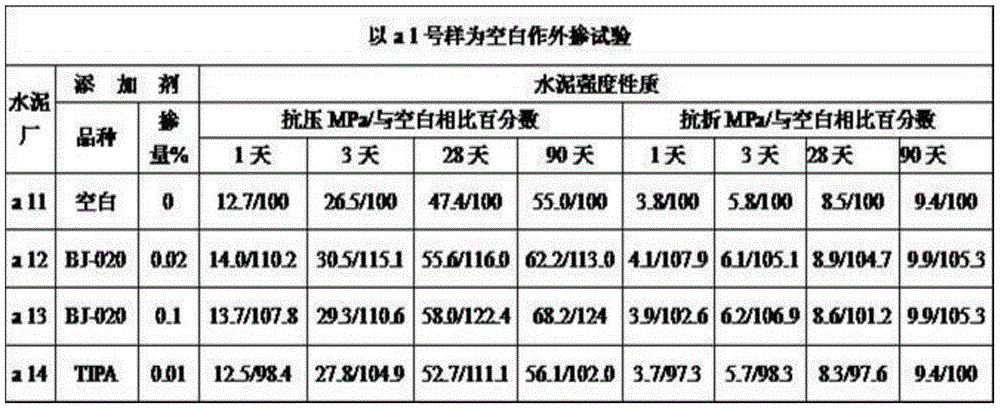

Embodiment 2

[0068] to 1M 3 The reactor was depressurized to -0.09Mpa, and 191kg of triisopropanolamine was pumped into the reactor, and then 539kg of concentrated sulfuric acid was added into the reactor, the stirring speed was set at 60r / min, and the temperature in the reactor was 45°C to 60°C. The reaction time is half an hour; the sodium sulfite solution with an effective content of 252kg is pumped into the kettle, the stirring speed is adjusted to 50r / min, and the pressure in the kettle is adjusted to normal pressure, the temperature in the kettle is 70°C, and the reaction condition is maintained at 3.5 h; then adjust to normal temperature and pressure in the reactor, add effective sodium hydroxide as an aqueous solution of 260kg, and the stirring speed is adjusted to 10r / min, after 20 minutes, the sampling analysis pH value is 10.0, then the reaction ends, and the product BJ of the present invention is obtained- 021.

[0069] The product BJ-021 of the present invention was compared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com