A functionalized polycarboxylate water reducer used in conjunction with silica fume and its preparation method

A technology of polycarboxylate and water reducer, which is applied in the field of functionalized polycarboxylate water reducer and its preparation, can solve the problems of unreachable effect, unstable concrete performance, no water reducer, etc., and achieve water reduction Effects of gray ratio, excellent slump retention, and low air entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

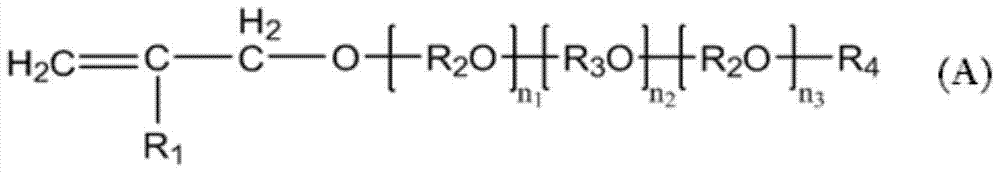

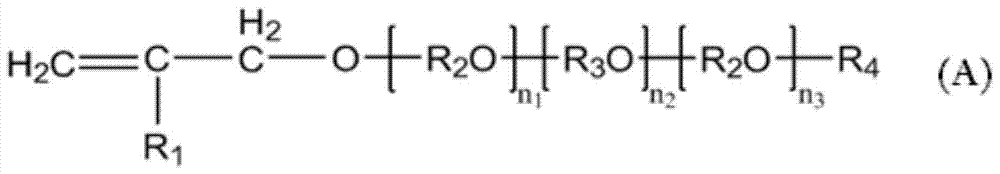

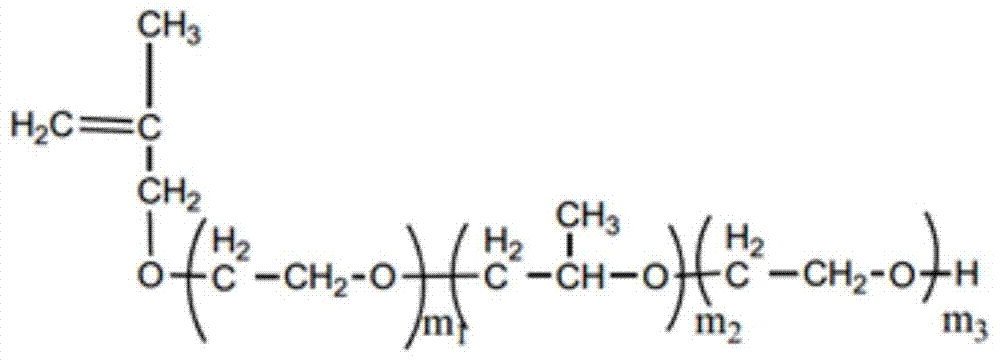

Method used

Image

Examples

Embodiment 1

[0034] The three-necked flask equipped with a stirrer was placed in a temperature-controlled electric heating mantle, and a three-block polyether monomer (ethylene oxide-propylene oxide-ethylene oxide three-block polyether monomer, molecular weight: 2600, wherein the weight ratio of ethylene oxide and propylene oxide in the molecular formula is 10:1) 155.1g, γ-methacryloxypropyltrimethoxysilane 27.4g, acrylic acid 21.5g, water 200g, stirring Evenly, heat up to 30°C, then add 7g of ammonium persulfate, and dropwise add the reducing agent aqueous solution obtained by dissolving 0.15g of reducing agent sodium sulfite in 2g of water and the chain transfer agent obtained by dissolving 0.3g of dithiopropanol in 3g of water aqueous solution, added dropwise for 4 hours, incubated for 2 hours, then added 60g of 30wt% NaOH solution to neutralize the reaction solution to pH=6~7, to obtain a functionalized polycarboxylate water reducer (molecular weight is about 33000), add water and dilu...

Embodiment 2

[0037] The three-necked flask equipped with a stirrer was placed in a temperature-controlled electric heating mantle, and a three-block polyether monomer (ethylene oxide-propylene oxide-ethylene oxide three-block polyether monomer, molecular weight: 4500, wherein the weight ratio of ethylene oxide and propylene oxide in the molecular formula is 18:1) 146g, vinyltrimethoxysilane 17.6g, vinyltriethoxysilane 18.9g, maleic anhydride 25.2g, water 200g, stir evenly, heat up to 40°C, then add 8.7g of potassium persulfate, dropwise add the reducing agent vitamin C 0.15g dissolved in 5g aqueous solution and the chain transfer agent dithiopropanol 0.3g dissolved in 5g aqueous solution, drop Add for 3 hours, heat preservation and aging for 1 hour, add 60g of 30wt% NaOH solution to neutralize the polymer to pH=6~7, obtain the functionalized polycarboxylate water reducer (molecular weight approx. is 27000), add water to dilute the water reducer mother liquor with a solid content of 10%, an...

Embodiment 3

[0039] The three-necked flask equipped with a stirrer was placed in a temperature-controlled electric heating mantle, and a three-block polyether monomer (ethylene oxide-propylene oxide-ethylene oxide three-block polyether monomer, molecular weight: 5500, wherein the weight ratio of ethylene oxide to propylene oxide in the molecular formula is 20:1) 146g, vinyl tris (β-methoxyethoxy) silane 23.9g, vinyl tris (β-methoxy Ethoxy) silane 12.6g, acrylic acid 7.1g, maleic anhydride 25.2g, water 200g, stir evenly, heat up to 35°C, then add ammonium persulfate 7g, dropwise add reducing agent sodium sulfite 0.15g to be dissolved in 10g aqueous solution and Dissolve 0.3 g of chain transfer agent dithiopropanol in 10 g of aqueous solution, add dropwise for 4 hours, heat-preserve and mature for 2 hours, add 60 g of 30 wt % NaOH solution to neutralize the polymer to pH = 6-7, and obtain a solid compound used in conjunction with silica fume. The functionalized polycarboxylate superplasticiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com