Concrete admixture, preparation method thereof and concrete targeted regulation and control method

A technology for concrete admixtures and admixtures, applied in the field of concrete admixtures and their preparation, and concrete targeted regulation, which can solve the problems of high manufacturing costs, inability to change from time to time, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

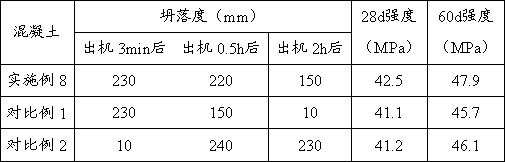

Examples

Embodiment 1

[0025] This embodiment provides a kind of concrete admixture, and it comprises slump retaining admixture and water reducing admixture; Concrete, slump retaining admixture is made of 0.1kg sodium gluconate, 1kg water reducer, 20kg slump retaining agent , 0.01kg of air-entraining agent, 0.03kg of defoaming agent and 78.86kg of water; the water-reducing admixture is made of 0.1kg of sodium gluconate, 17kg of water-reducing agent, 1kg of slump-retaining agent, 0.01kg Air-entraining agent, 0.03kg defoamer and 81.86kg water are mixed. Among them, the water-reducing agent is a commercially available polycarboxylate-type water-reducing agent. Specifically, the V2 water-reducing agent from Qingdao Guoji Technology Group can be used, and its water-reducing rate can reach more than 40%; the slump-retaining agent is a commercially available The polycarboxylate type slump-retaining agent can specifically adopt the V3 slump-retaining agent from Qingdao Guoji Technology Group, and its water ...

Embodiment 2

[0027] This embodiment provides a kind of concrete admixture, and it comprises slump retaining admixture and water reducing admixture; Concrete, slump retaining admixture is made of 5kg sodium gluconate, 5kg water reducer, 30kg slump retaining agent, 0.08kg of air-entraining agent, 0.1kg of defoamer and 59.82kg of water are mixed; the water-reducing admixture is composed of 5kg of sodium gluconate, 27kg of water-reducing agent, 5kg of It is made by mixing air agent, 0.1kg defoamer and 62.82kg water. Among them, the water-reducing agent is a commercially available polycarboxylate-type water-reducing agent. Specifically, the V2 water-reducing agent from Qingdao Guoji Technology Group can be used, and its water-reducing rate can reach more than 40%; the slump-retaining agent is a commercially available The polycarboxylate type slump-retaining agent can specifically adopt the V3 slump-retaining agent from Qingdao Guoji Technology Group, and its water reduction rate is lower than 2...

Embodiment 3

[0029] This embodiment provides a kind of concrete admixture, and it comprises slump retaining admixture and water reducing admixture; Concrete, slump retaining admixture is made of 1.5kg sodium gluconate, 2kg water reducer, 22kg slump retaining agent , 0.02kg of air-entraining agent, 0.04kg of defoamer and 74.44kg of water; the water-reducing admixture is made of 1kg of sodium gluconate, 25kg of water-reducing agent, 2kg of slump-retaining agent, and 0.04kg of It is made by mixing air-entraining agent, 0.06kg defoamer and 71.9kg water. Among them, the water-reducing agent is a commercially available polycarboxylate-type water-reducing agent. Specifically, the V2 water-reducing agent from Qingdao Guoji Technology Group can be used, and its water-reducing rate can reach more than 40%; the slump-retaining agent is a commercially available The polycarboxylate type slump-retaining agent can specifically adopt the V3 slump-retaining agent from Qingdao Guoji Technology Group, and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com