Front roller bearing for drawing frame

A technology for drawing frames and bearings, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc. It can solve problems affecting sliver, increased bearing resistance, lack of oil in bearings, etc., and achieves extension Refueling cycle, avoid heat damage, ensure the effect of lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

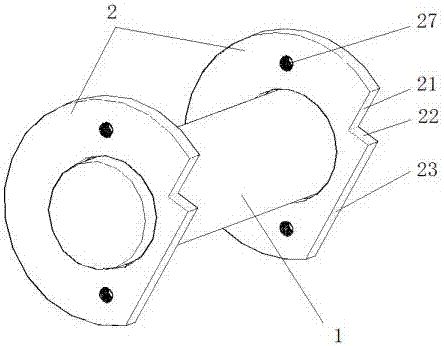

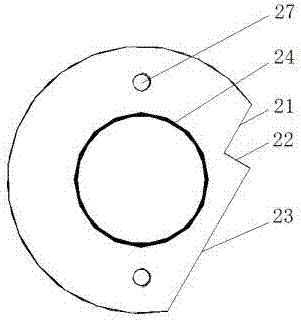

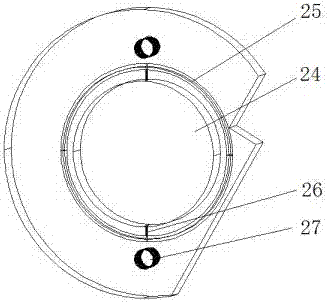

[0016] Such as Figure 1 to Figure 3 As shown, a front roller bearing of a draw frame includes a bearing 1 and retaining rings 2 symmetrically arranged on both sides of the bearing. The retaining ring 2 is made of gray cast iron. At least one fixed The screw hole 27 used, its outer ring is recessed inwardly to form the first folded edge 21 connected, the second folded edge 22 and the third folded edge 23, the first folded edge 21 and the third folded edge 23 are arranged in parallel, and the second folded edge 21 is arranged in parallel. The folded edge 22 is perpendicular to the first folded edge 21 and the third folded edge 23, and the distances from the first folded edge 21 and the third folded edge 23 to the center of the retaining ring 2 are respectively 3 / 5 of the outer diameter of the retaining ring 2 and 4 / 5 The outer diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com