Ribbon-like-filament-wrapped yarn for metallic garment of fencing and production method of ribbon-like-filament-wrapped yarn

A technology of wrapping yarn and flat yarn, which is applied in yarn, textile, papermaking, fiber treatment, etc. It can solve the problems of coarse conductivity of tin-plated phosphor copper wire and poor softness of conductive yarn, so as to reduce the amount of copper used and cover The number of windings, good coverage, and the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

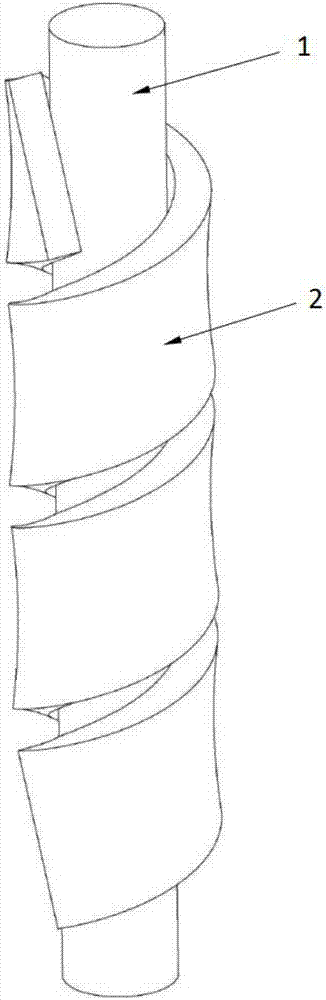

[0033] A flat yarn wrapping yarn for metal clothing fabrics for fencing sports, comprising a core yarn 1 and an outer wrapping yarn 2 spirally wound on the core yarn 1, the outer wrapping yarn 2 is a silver-plated red copper flat wire, and the cross-section of the silver-plated red copper flat wire is The aspect ratio is 20, and the core yarn 1 is elastic yarn.

[0034] The long side of the cross-section of the silver-plated red copper flat wire is 200 μm, and the short side of the cross-section of the silver-plated red copper flat wire is 10 μm.

[0035] The core yarn 1 is a nylon yarn or a polyester yarn with a fineness of 60D.

[0036] The wrapping density of the covering yarn 2 is 7 revolutions / cm.

[0037] The preparation method of the flat filament wrapped yarn of the present embodiment may further comprise the steps:

[0038] S1. Select copper flat wire with a cross-section of 200 μm on the long side and 10 μm on the short side as the raw material of the conductive ya...

Embodiment 1

[0044] Compared with embodiment 1, the long side of the silver-plated red copper flat wire cross-section of present embodiment 2 is 400 μm, and the short side of the silver-plated red copper flat wire cross-section is 20 μm.

[0045] The core yarn 1 is a nylon yarn or a polyester yarn with a fineness of 100D.

[0046] The wrapping density of the covering yarn 2 is 9 revolutions / cm.

Embodiment 3

[0048] Compared with Example 1, the long side of the silver-plated red copper flat wire cross-section of the present embodiment 3 is 300 μm, and the short side of the silver-plated red copper flat wire cross-section is 15 μm.

[0049] The core yarn 1 is nylon yarn or polyester yarn with a fineness of 80D.

[0050] The wrapping density of the covering yarn 2 is 8 revolutions / cm.

[0051] Aiming at the various defects of traditional products, the present invention uses copper microwires with a side length ratio of 20 as the conductive material. The bending stiffness of the material is very small, which makes the wrapping yarn soft; The conductive wire has good softness retention and good conductivity after being plated with silver; the silver-plated flat wire has low rigidity and bending deformation, and can be used to cover thinner core yarn. Small, wrapped yarn is softer; 300μm wide silver-plated copper flat wire has good covering ability, and the covering area of copper wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com