Sealed gas chamber for testing comprehensive performance of optical fiber gas sensor

A comprehensive performance testing, gas sensor technology, applied in the field of optical fiber, can solve the problems of poor air tightness, too large sealing box, inconvenient operation, etc., to achieve the effect of small size, large operating window, and convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The essential features and remarkable progress of the present invention will be clarified below through specific embodiments.

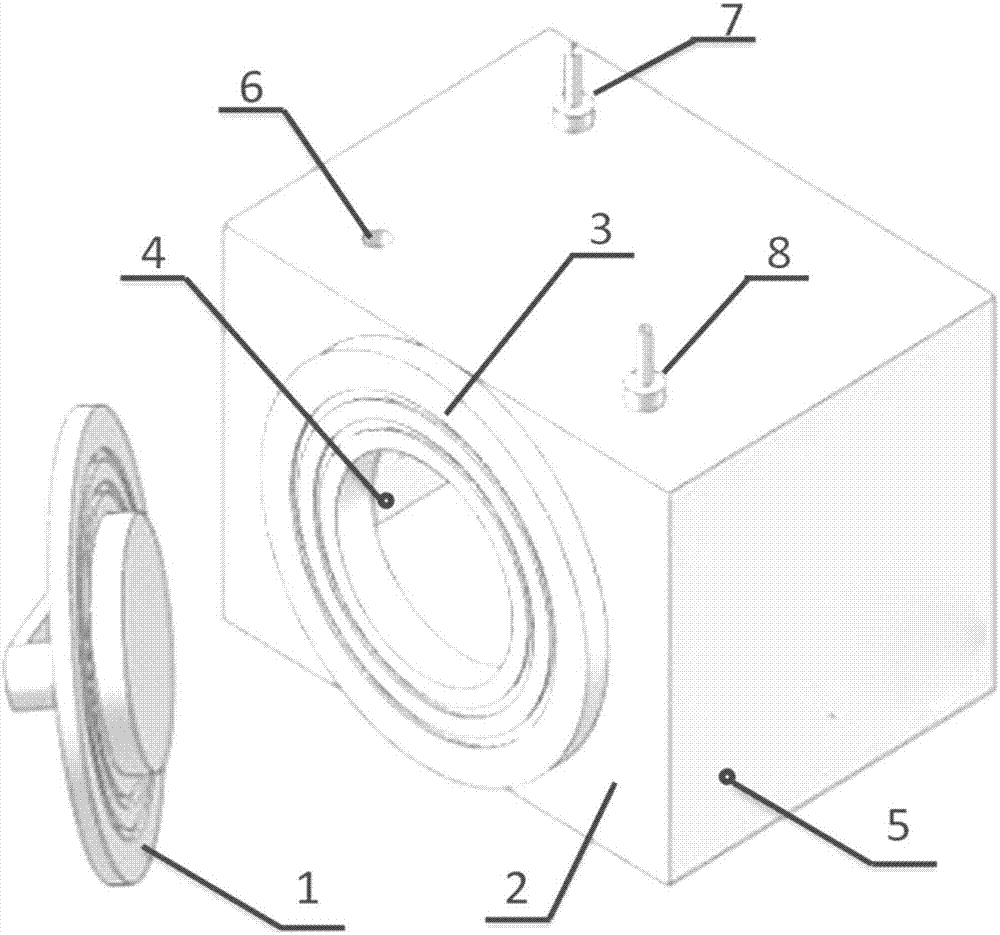

[0016] A sealed gas chamber used for comprehensive performance testing of optical fiber gas sensor devices, comprehensively considering the actual requirements in the experimental process and the airtightness of the sealed gas chamber. The size of the air chamber designed by the present invention is 30cm×22cm×22cm. The airtight air chamber is mainly composed of a sealing cover 1 and a main body 2, wherein the main body 2 of the airtight air chamber retains the incident fiber hole 4 and the outgoing fiber hole 5, and its diameter is the diameter of a single-mode fiber jumper, about 125 Micron. Because of the small size of this hole, hot-melt glue was used in the fabrication process to ensure airtightness. The air inlet 7 and the air outlet 8 are designed as a hollow cylinder with an outer diameter of 8mm and a height of 30mm, so that the trach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com