Mura treatment method specific to ultrahigh resolution panel

A technology of ultra-high resolution and processing method, applied in the field of liquid crystal displays, can solve the problems of affecting the accuracy of compensation data and high cost of industrial cameras, and achieve the effect of reducing high costs and accurate mura compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

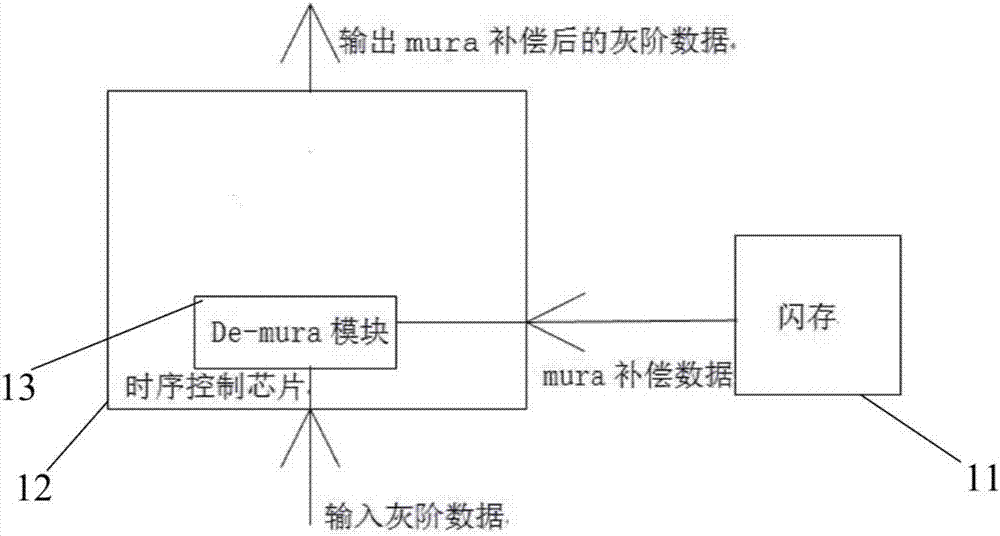

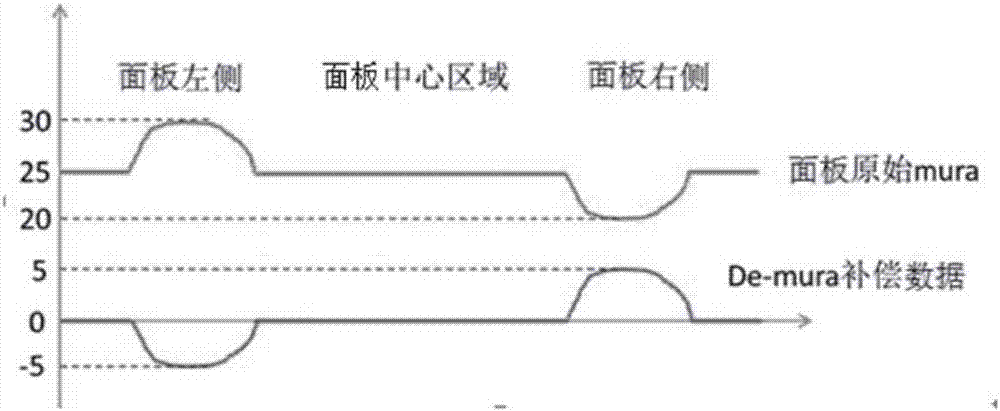

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

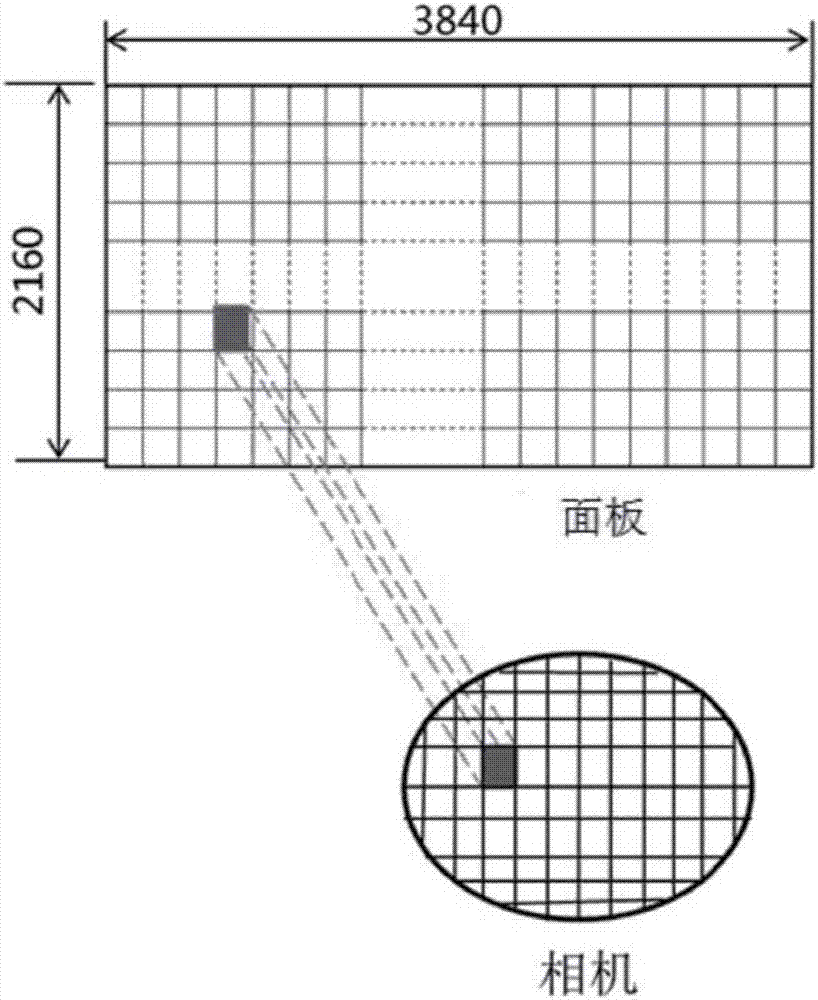

[0032] see Figure 6 , which is a flow chart of the mura processing method for ultra-high resolution panels in the present invention. The method mainly includes:

[0033] Step 10. Use an industrial camera to take pictures of the actual mura state of the entire panel in sub-areas according to the resolution of the industrial camera. When the grayscale display of a certain area of the panel is photographed, the remaining areas of the panel display 0 grayscale;

[0034] Take an industrial camera that only supports 4K2K resolution (3840*2160 pixels) panels to shoot 8K4K resolution (7680*4320 pixels) panels as an example, centering on the center of the 8K4K resolution panel, only display 4K2K resolution in the center area of the panel area, and the remaining 3 / 4 areas are all displayed in a black screen (0 gray scale);

[0035] Step 20. Obtain the mura compensation data matrix for each area of the panel according to the pre-acquired correspondence between grayscale and brig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com