Method for operating brake system, and brake system executing same

A braking system, wheel brake technology, applied in the direction of brake transmission, brake, transportation and packaging, etc., can solve the problems of system burst, damage to electromechanical actuators, etc., to achieve the effect of protecting damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

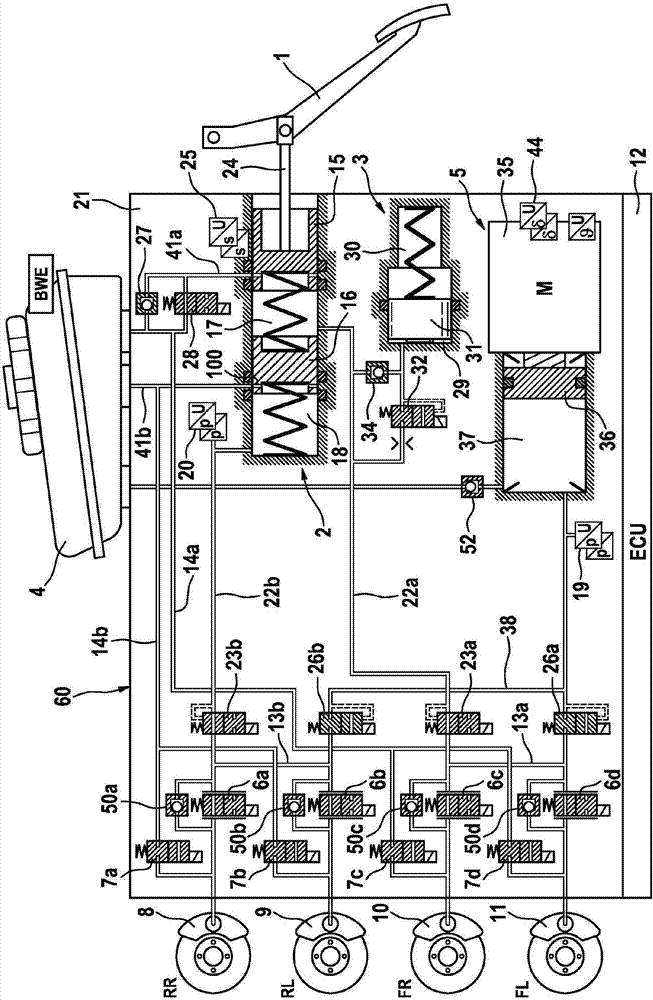

[0034] figure 1 An exemplary embodiment of a braking system for carrying out the method according to the invention is schematically shown in . The brake system basically comprises a brake master cylinder 2 actuatable by means of an operating pedal or brake pedal 1 , an analog device 3 cooperating with the brake master cylinder 2 , pressure medium storage container 4, an electrically controlled pressure supply device 5, an electrically controlled pressure modulation device for adjusting the wheel-dependent brake pressure, and an electronic control and regulation unit 12, said pressure supply device is composed of a hydraulic pressure The chamber 37 is constituted by a cylinder-piston assembly whose piston 36 can be moved by an electromechanical actuator.

[0035]The pressure modulation device, which is not shown in detail, comprises, by way of example, an inlet valve 6 a - 6 d and an outlet valve 7 a - 7 d for each hydraulically actuatable wheel brake 8 , 9 , 10 , 11 of a moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com