Polishing composition and polishing method

A composition and technology of organic compounds, applied in polishing compositions containing abrasives, grinding machine tools, grinding devices, etc., can solve the problems of corrosion, surfactant-promoted etching, weak resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

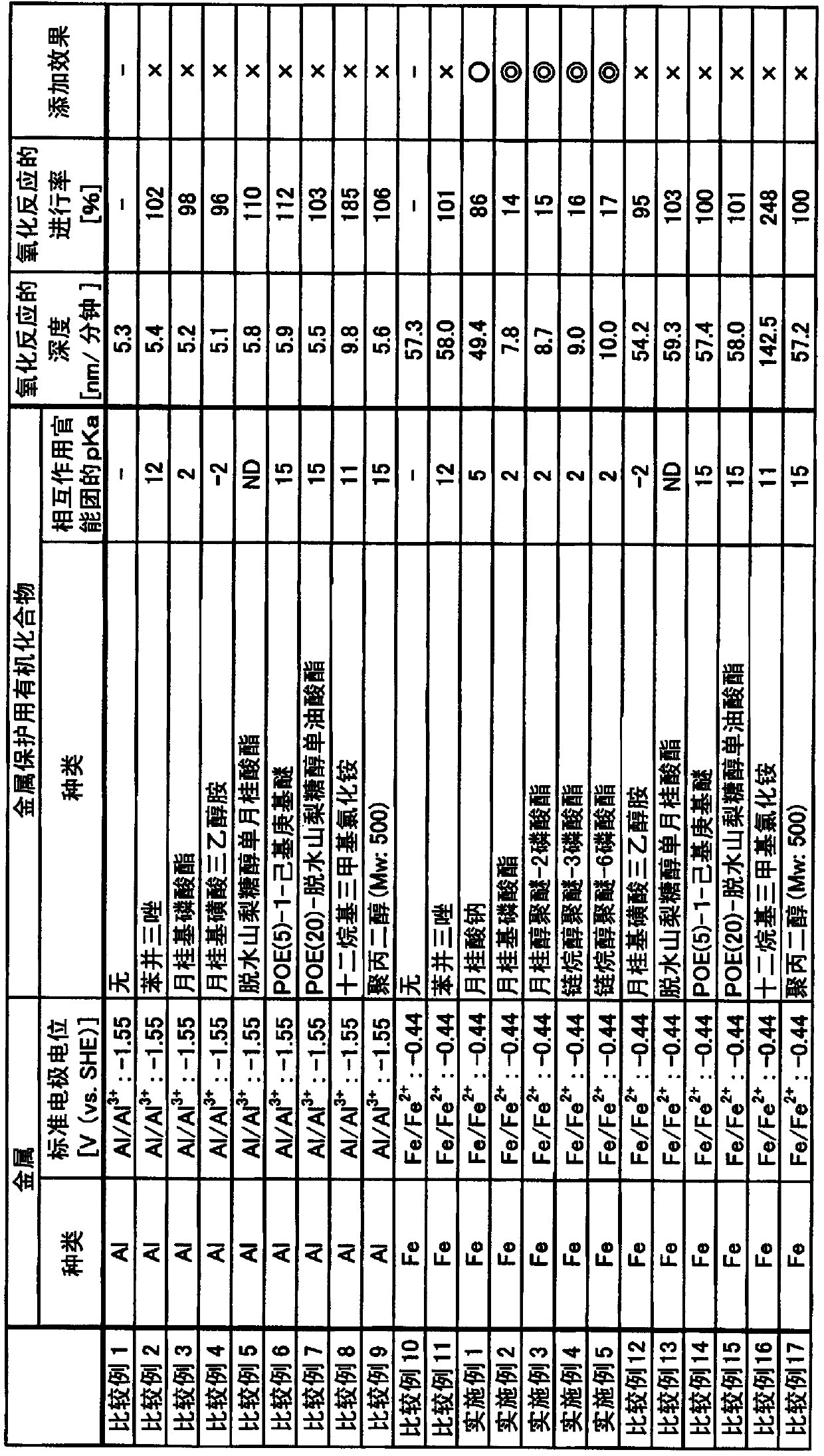

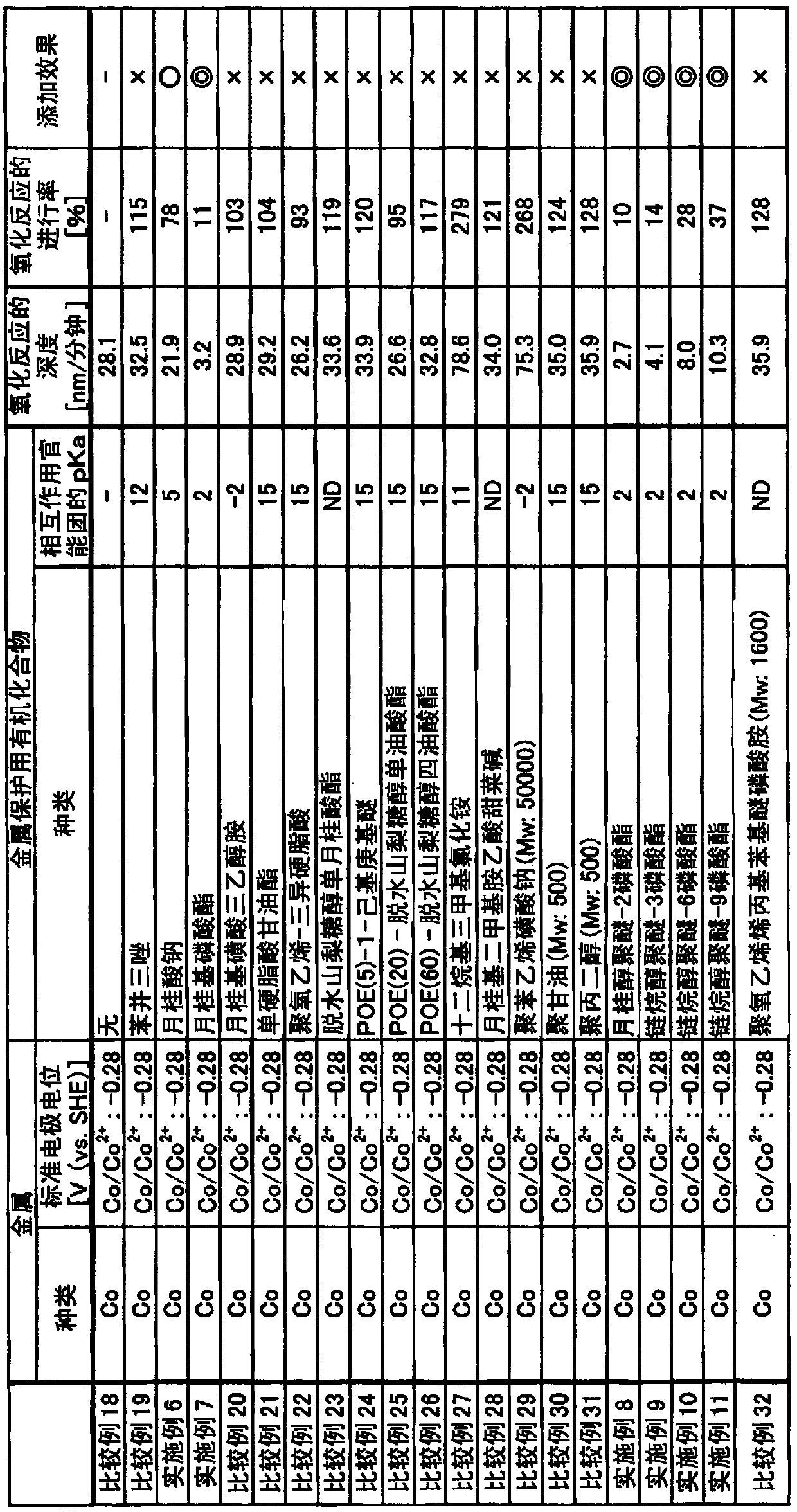

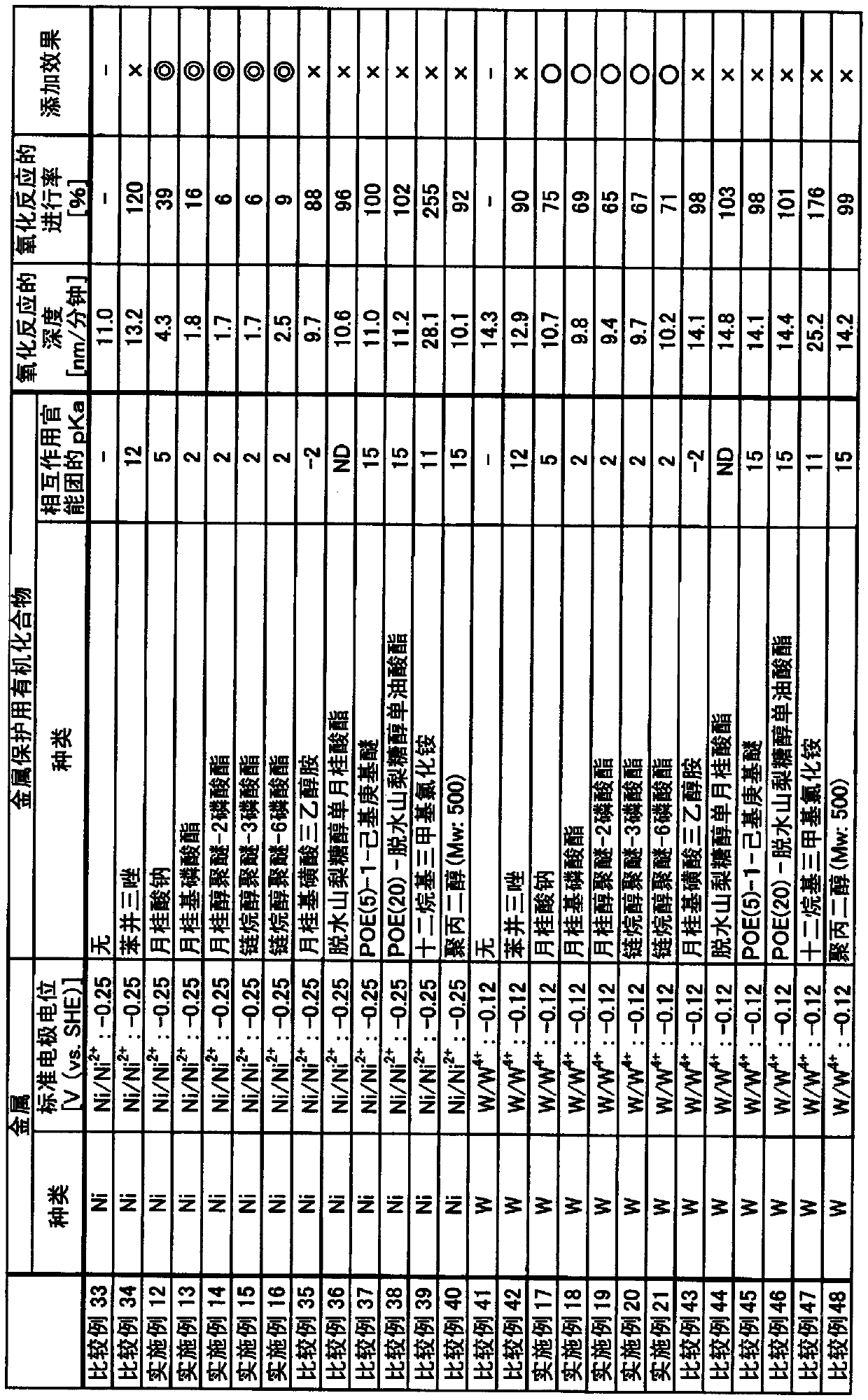

[0013] One embodiment of the present invention will be described in detail. The polishing composition of the present embodiment is a polishing composition for polishing an object containing a transition metal having a standard electrode potential of -0.45 V to 0.33 V, and contains abrasive grains and an organic compound for metal protection. . The metal-protecting organic compound has an interactive functional group that interacts with an object to be polished and an inhibitory functional group that inhibits the approach of abrasive grains to the object to be polished.

[0014] When an object to be polished containing a transition metal having a standard electrode potential of -0.45 V to 0.33 V is polished using the polishing composition of the present embodiment, the object to be polished is less likely to be etched or corroded. The reason for this will be described in detail below.

[0015] In order to suppress etching and corrosion of metals caused by polishing compositio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| humidity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com