Display substrate and manufacturing method thereof, display panel and display device

A technology for a display substrate and a manufacturing method is applied in the fields of display panels, display devices, display substrates and manufacturing methods thereof, and can solve the problems affecting the yield rate of the display panel, the difficulty of proceeding in the process, and the uneven coating of photoresist on a flat layer. , to achieve the effect of improving yield, fast coating speed and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

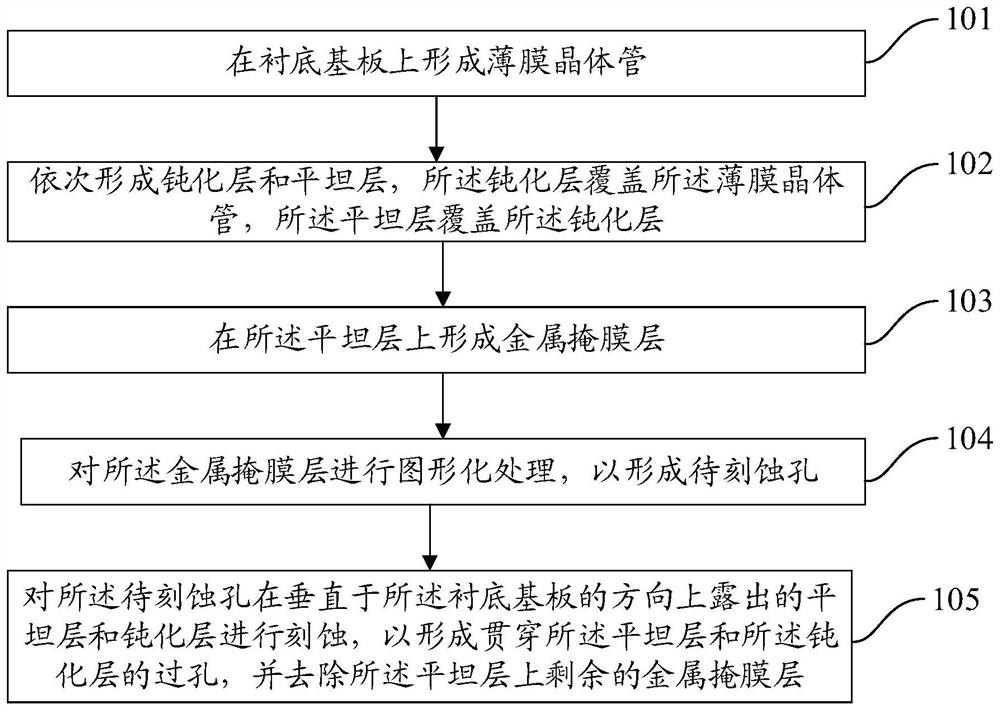

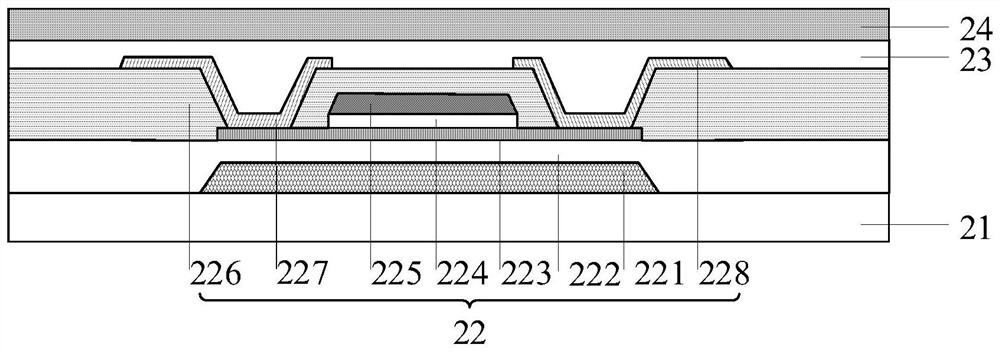

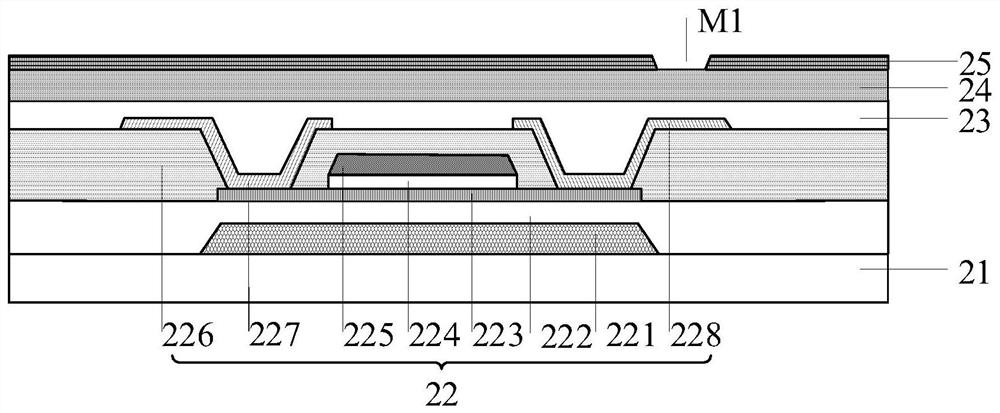

[0051] In order to make the above objects, features, and advantages of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0052] At present, when an inkjet printing process is made on the display substrate, it is often necessary to display a substrate having good flatness. During the actual production process, in order to reduce the IR DROP (pressure drop) of the large size display panel, it is necessary to increase the film. The thickness of the source or drain of the transistor, so that the film layer difference between the display substrate is increased, resulting in a decrease in flatness, in order to improve the flatness of the display substrate, it is necessary to increase the thickness of the flat layer; in addition, in order to improve the source or drain and anode The capacitance between the parasitic capacitance is also needed to increase the thickness of the flat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com