Method and apparatus for the quality control of a multiplicity of melt-spun fibre strands of a fibre tow

A quality monitoring and sliver technology, applied in the field of quality monitoring and equipment for multiple melt-spun fiber slivers of tow, can solve the problem of costly image analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

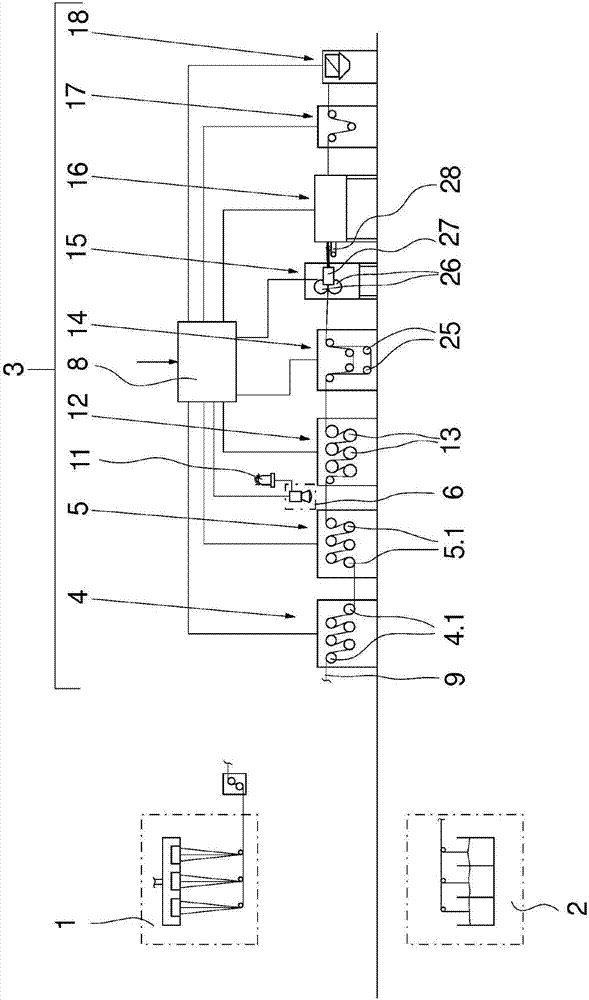

[0030] exist figure 1 A system for making synthetic staple fibers from tow is schematically shown in . The system has a processing device 3 to receive the tow for processing and splitting. The processing device 3 is also known in the technical field as a so-called fiber production line for the continuous production of staple fibers from tows. exist figure 1 The treatment device 3 shown in can thus be combined with the melt-spinning device 1 or optionally with the can station 2 . The treatment device 3 is thus suitable for both a one-step process and a two-step process for producing short fibers.

[0031] exist figure 1 In , the melt-spinning device 1 and the can station 2 are shown symbolically and will not be further explained here.

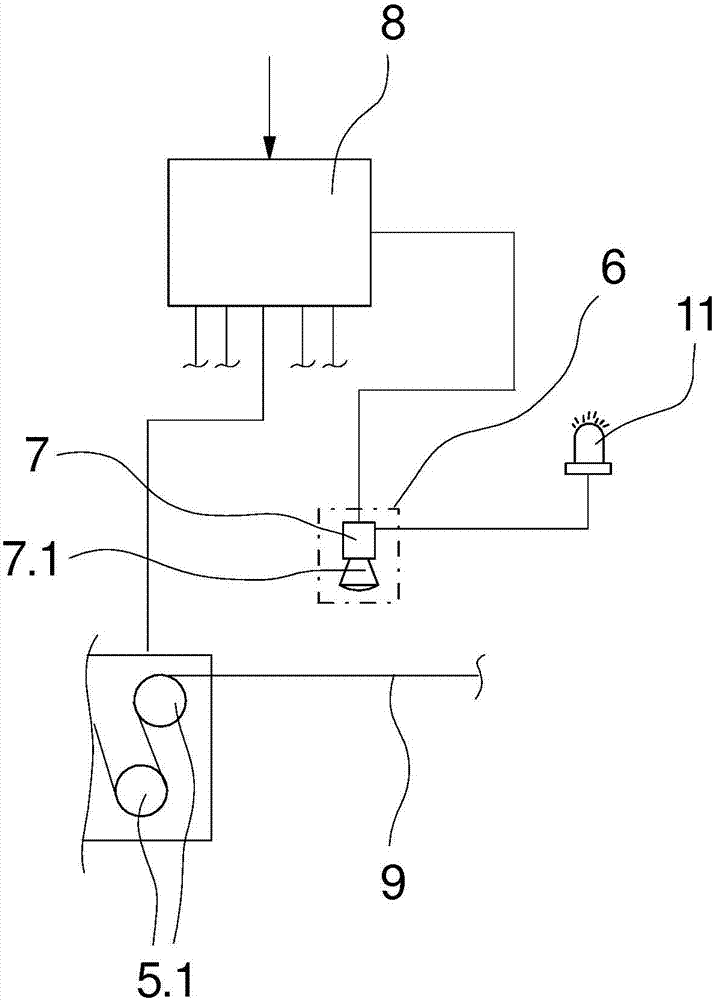

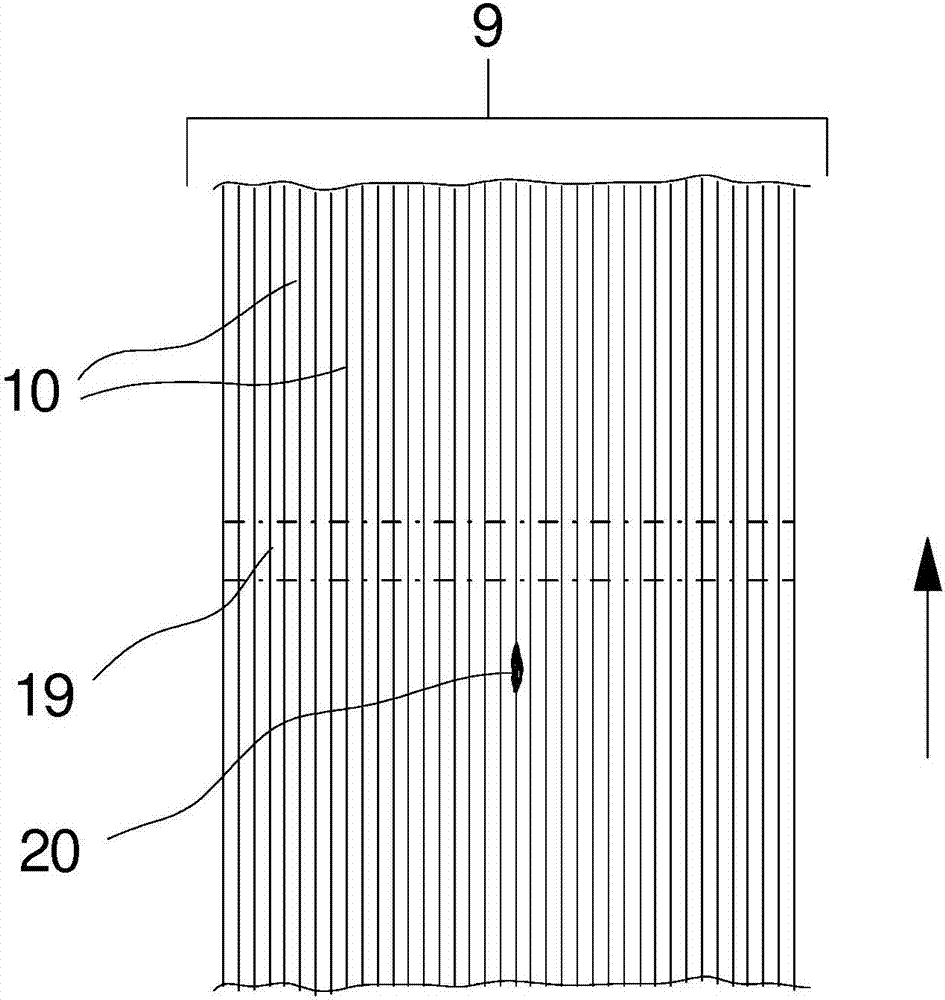

[0032] The processing device 3 comprises in this embodiment a plurality of stretching devices 4 and 5, a sizing device 12, a distance shifting device 14, a crimping device 15, a belt dryer 16, a draw adjustment device 17 and a Cutting devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com