Nonaqueous electrolytic solution and nonaqueous electrolytic solution secondary battery using the same

A non-aqueous electrolyte and secondary battery technology, applied in the direction of non-aqueous electrolyte batteries, secondary batteries, non-aqueous electrolytes, etc., can solve the problems of battery stability reduction, battery capacity reduction, deterioration, etc., to achieve suppression of gas generation, The effect of excellent discharge load characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

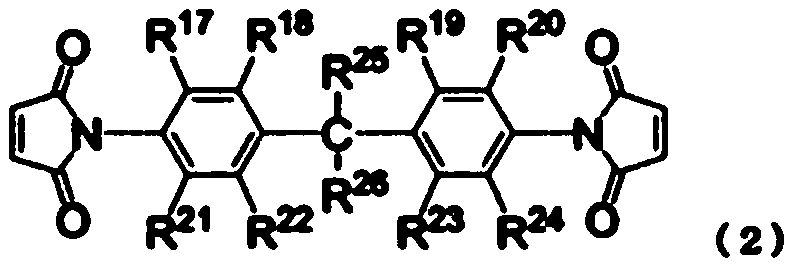

[0323] Under a dry argon atmosphere, ethylene carbonate (hereinafter, EC), ethylmethyl carbonate (hereinafter, EMC) and diethyl carbonate (hereinafter, DEC) were mixed so as to be 30% by volume, 40% by volume, and 30% by volume, respectively. volume % to make LiPF 6 Dissolved in the non-aqueous solvent thus mixed, LiPF 6 The concentration was 1.2M, and 2% by mass of vinylene carbonate and 2% by mass of fluoroethylene carbonate were added. Further, 0.3% by mass of Compound 2-10 was added to prepare a non-aqueous electrolytic solution.

Embodiment 2-1

[0344] Under a dry argon atmosphere, ethylene carbonate (hereinafter, EC), ethylmethyl carbonate (hereinafter, EMC) and diethyl carbonate (hereinafter, DEC) were mixed so as to be 30% by volume, 40% by volume, and 30% by volume, respectively. volume % to make LiPF 6 Dissolved in the non-aqueous solvent thus mixed, LiPF 6 The concentration was 1.2M, and 2% by mass of vinylene carbonate, 2% by mass of fluoroethylene carbonate, and 1% by mass of adiponitrile were added. Furthermore, 0.3% by mass of Compound 2-10 was added to prepare a non-aqueous electrolyte solution. Except having used this non-aqueous electrolytic solution, it carried out similarly to Example 1-1, and produced the sheet-shaped battery.

Embodiment 3-1

[0354] Under a dry argon atmosphere, ethylene carbonate (hereinafter, EC), ethylmethyl carbonate (hereinafter, EMC) and diethyl carbonate (hereinafter, DEC) were mixed so as to be 30% by volume, 40% by volume, and 30% by volume, respectively. volume % to make LiPF 6 Dissolved in the non-aqueous solvent thus mixed, LiPF 6 The concentration was 1.2M, and 2% by mass of vinylene carbonate, 2% by mass of fluoroethylene carbonate, and 1% by mass of adiponitrile were added. Furthermore, 0.3% by mass of Compound 2-10 was added to prepare a non-aqueous electrolyte solution. Except having used this non-aqueous electrolytic solution, it carried out similarly to Example 1-1, and produced the sheet-shaped battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com