Spiral-climbing bamboo branch feller

A technology of bamboo branch machine and spiral, which is applied in the direction of agricultural machinery and tools, cutting tools, cutting equipment, etc., can solve the problems of high labor intensity, high labor intensity of bamboo and bamboo branches, and single acquisition method of bamboo branches, so as to achieve high work efficiency and guarantee The effect of processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

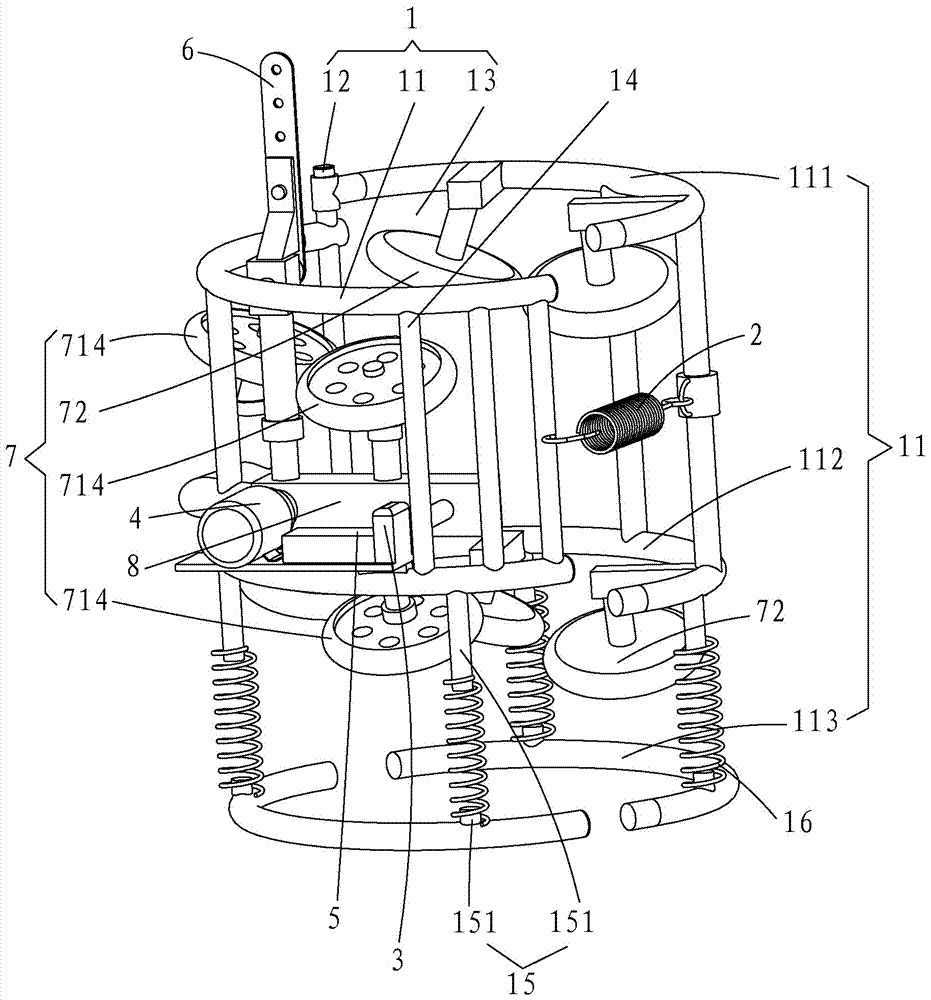

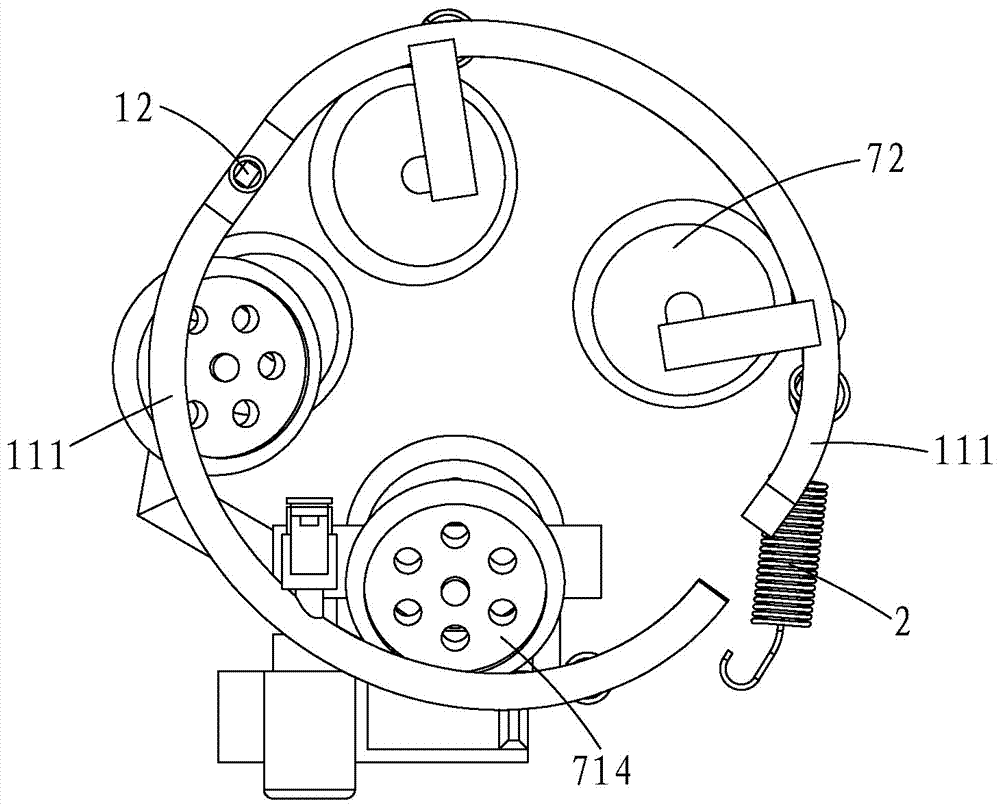

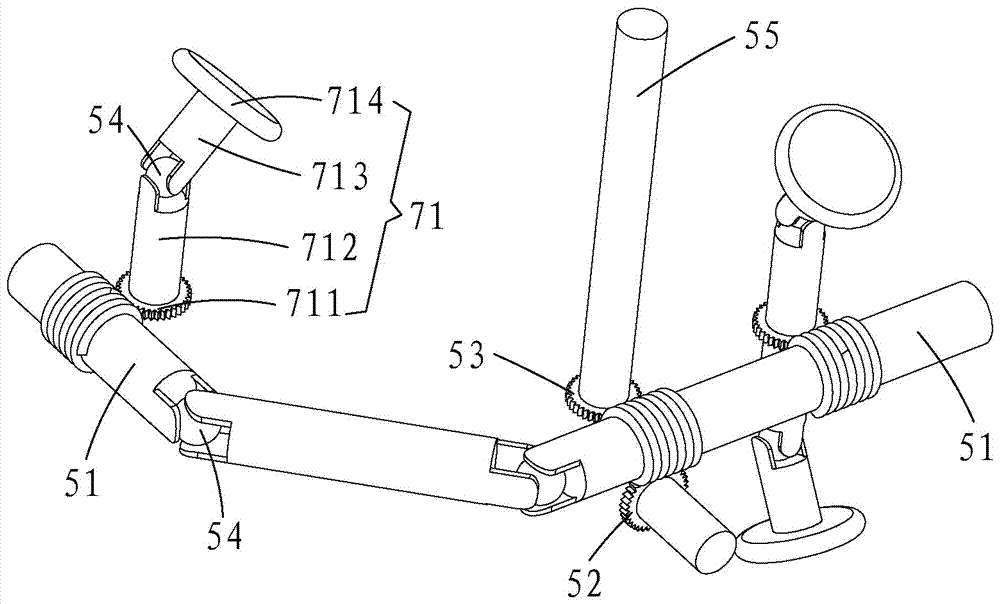

[0020] see figure 1 and figure 2 As shown, a spiral climbing and felling bamboo branch machine 100 includes a frame 1, a clamping part 2, a controller 3, an electric motor 4, a power transmission mechanism 5, a pruning saw 6, and a plurality of climbing wheels 7. A remote controller (shown in a diagram) and a lithium battery 8; the frame 1 includes two binding half-ring units 11 and a rotating shaft 12, and one end of the two binding half-ring units 11 can be rotatably fixed on the rotating shaft 12 , and the two binding half-ring units 11 embrace to form a binding space 13; one end of the clamping part 2 is fixed on the free end of a binding half-ring unit 11, and one end of the clamping part 2 hooks another binding half-ring unit 11 The free end; the clamping part 2 is a tension spring. The controller 3 controls and connects the motor 4, and the motor 4 drives and connects the power transmission mechanism 5; Interlocking arrangement, and the pruning saw 6 protrudes from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com