Multi-phase microstructure nickel-chromium-iron-series high-temperature alloy and manufacturing method thereof

A technology of superalloy and multi-phase structure, applied in the field of nickel-chromium-iron superalloys, can solve the problems of difficult to grow large pieces, low plasticity of casting alloys, poor machinability of dispersion-strengthened alloys, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

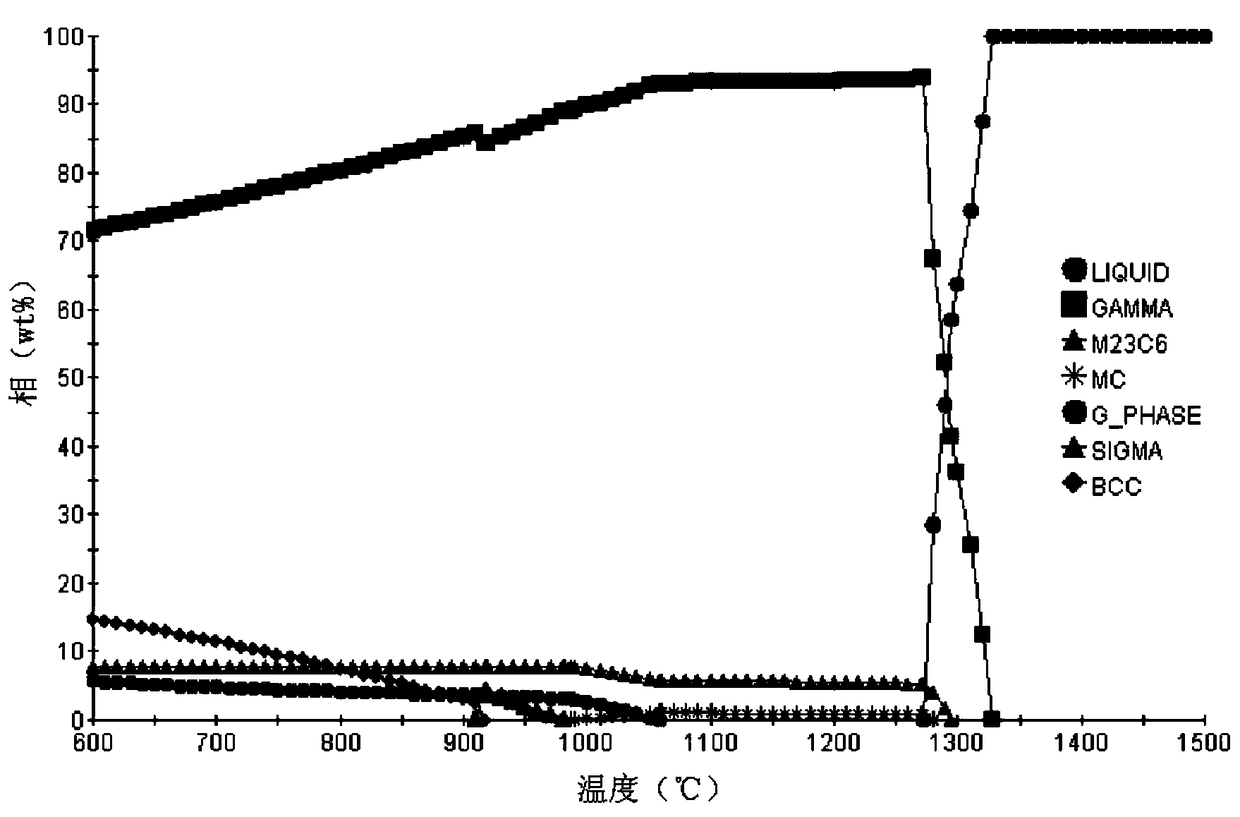

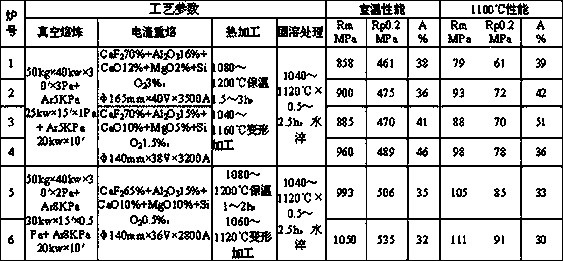

[0036] Alloy component and content of the present invention are as shown in table 1:

[0037] Table 1 Component contents of nickel-chromium-iron superalloys

[0038]

[0039]Above-mentioned superalloy is prepared according to the following method:

[0040] 1) Vacuum induction furnace melting

[0041] Put Ni, Nb, W, Cr, and Fe into a vacuum induction furnace according to the above ratio, and refine at 1550-1650°C for 15-45 minutes after melting, and the vacuum degree is better than 5Pa; add C, Si, Mn, and melt at 1500-1500 Refining at 1600°C for 10-25 minutes, the vacuum degree is better than 3Pa; then add Al, B, V, La under the protection of argon, and after melting, refine at 1450-1550°C for 5-15 minutes, and then cast it into an electroslag remelting electrode rod ;

[0042] 2) Electroslag remelting

[0043] with CaF 2 、Al 2 o 3 , CaO, MgO and SiO 2 As a slag, the weight percentage of each component of the slag: CaF 2 50-70%, Al 2 o 3 10-30% for CaO, 5-15% for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com