Food preservation processor

The technology of a cooking machine and a base is applied in the field of food preservation cooking machines, which can solve the problems of insufficient relative vacuum and inability to play an insurance role, and achieve the effect of good anti-oxidation level and easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

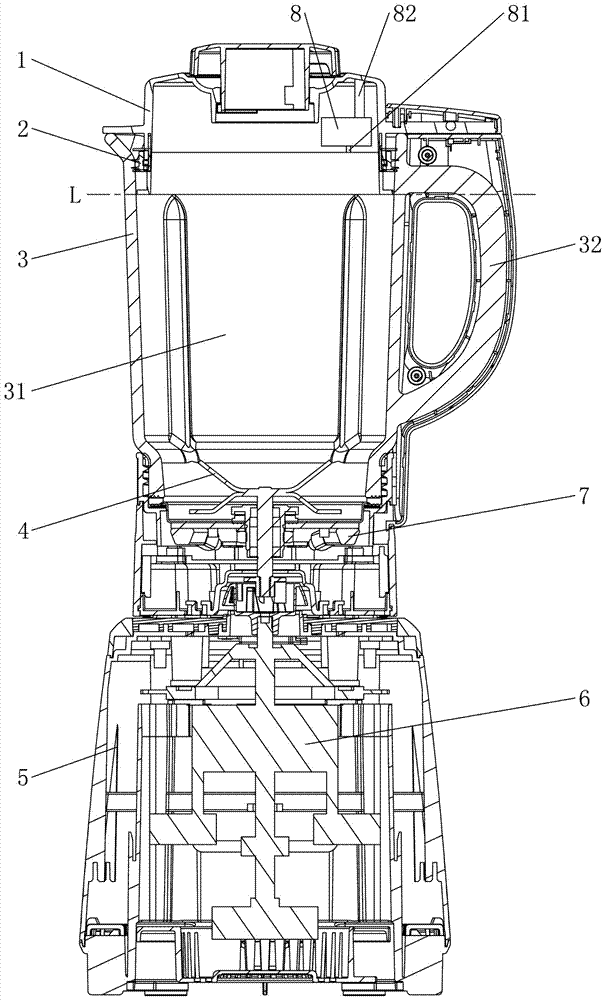

[0027] Embodiment one, see figure 1 As shown, a food preservation cooking machine includes a control circuit, a container 3, a stirring device 4 arranged in the inner cavity 31 of the container 3, a motor 6 for driving the stirring device 4, and an air pump for extracting the air inside the container 3 Device 8, the container 3 is provided with an opening, the opening is provided with a sealing cover 1, and the air extraction device 8 and the motor 6 are electrically connected to the control circuit respectively. The air extraction device 8 refers to: when the sealing cover 1 opens the container 3 After sealing and starting the pumping device 8, the relative vacuum degree of the inner cavity 31 of the container 3 is within a certain period of time in the pumping device 8 of -81Kpa to -99Kpa; the pumping device 8 is provided with a pumping port 81 and an exhaust port. The port 82 and the suction port 81 lead to the closed space above the inner cavity 31 of the container 3 and c...

Embodiment 2

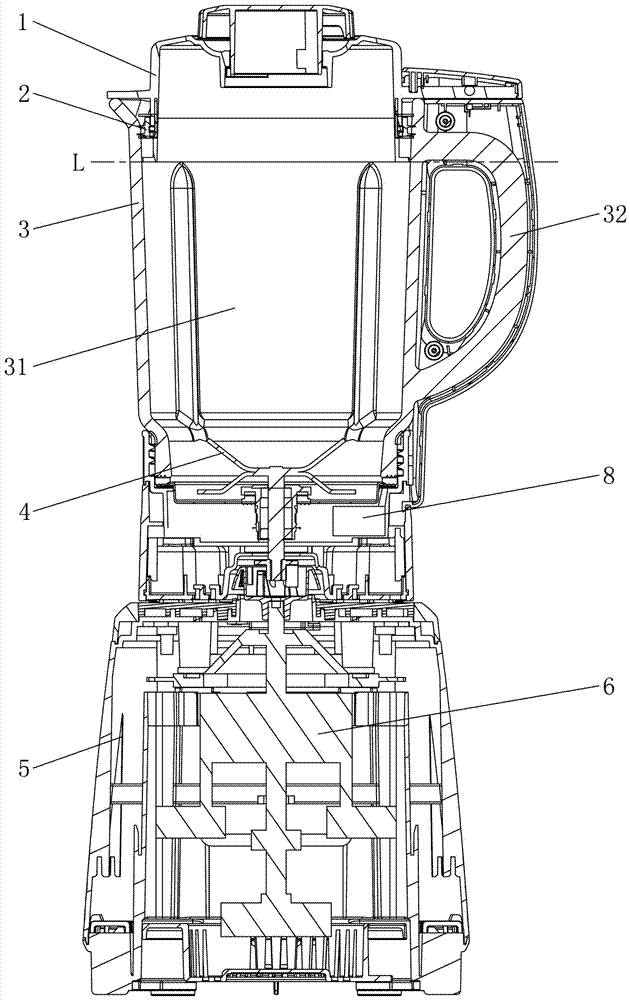

[0037] Embodiment two, the difference with embodiment one is: see figure 2 As shown, the air extraction device is arranged on the base 5 .

Embodiment 3

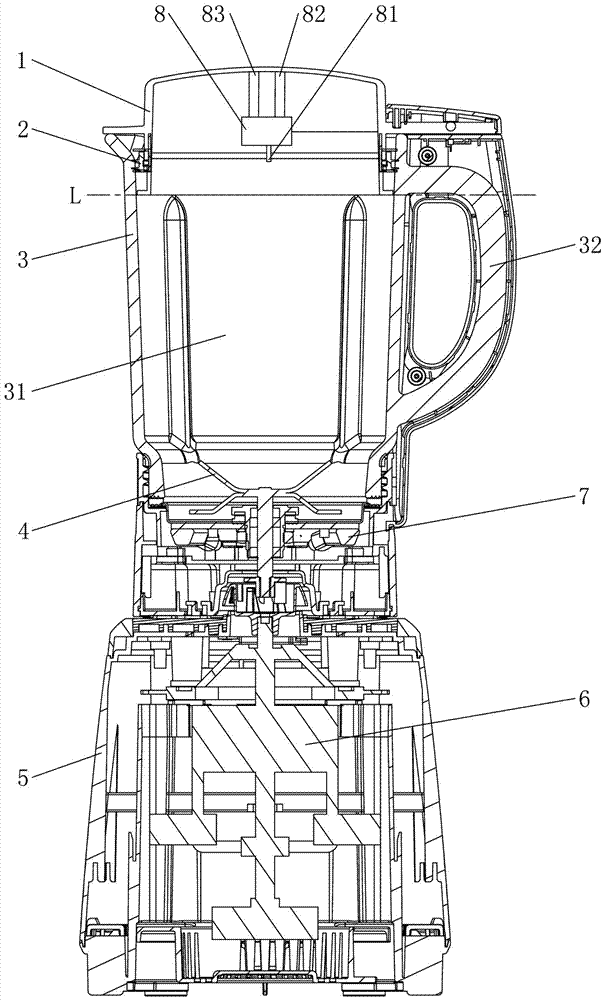

[0038]Embodiment three, the difference with embodiment one is: see image 3 As shown, the air extraction device 8 is an air extraction device with a ventilation function, and has an air extraction port 81, an exhaust port 82 and an air intake port 83, wherein the air extraction port 81 can have air extraction and exhaust functions, and when required When vacuuming, the suction port 81 pumps air, the exhaust port 82 exhausts, and the suction port 83 has no airflow; when it is necessary to inject air into the inner cavity 31 of the container 3, the control circuit controls the suction port 83 to communicate with the suction port 81, The air can be injected into the inner cavity 31 of the container 3 by itself.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com