Forming method of double-faced complex cavity of multilayer ceramic substrate

A technology of ceramic substrates and multilayer ceramics, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of substrate bending plane size, unbalanced cavity force, large difference in stiffness, etc., to improve integration and precision, facilitate The effect of assembly and internal leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

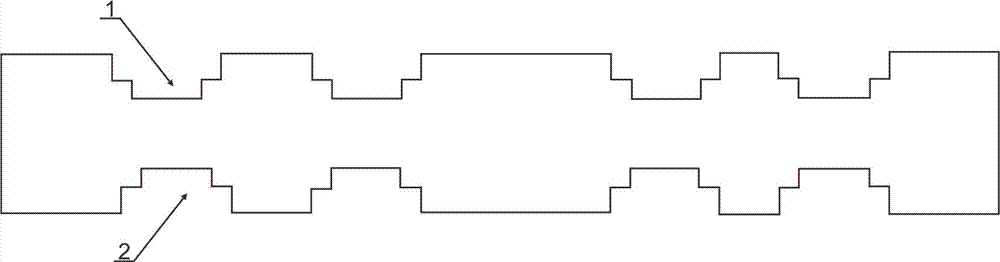

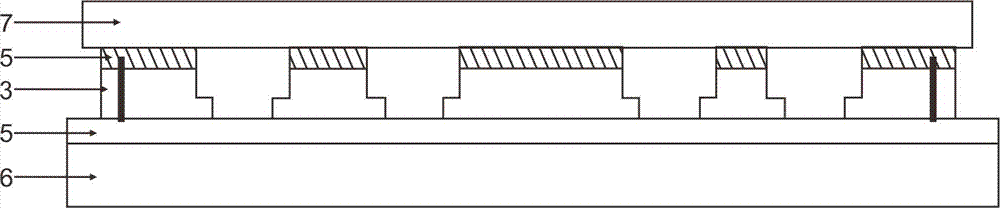

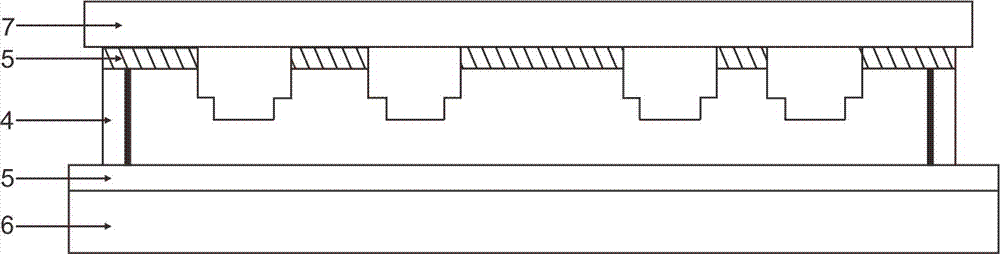

[0037] The invention provides a method for forming a double-sided complex cavity of a multilayer ceramic substrate. The method is suitable for a multilayer ceramic substrate with cavities on both sides. The double-sided complex cavity mentioned in the present invention can refer to Both surfaces have cavities, and the complex cavities mentioned herein do not refer to cavities with a specific degree of complexity, that is, there are no restrictions on the shape, structure and number of cavities.

[0038] The multilayer ceramic substrate includes several single-layer ceramic substrates, that is, the multilayer ceramic substrate is formed by stacking multiple single-layer ceramic substrates one by one. Therefore, the shape and depth of the cavity of the multilayer ceramic substrate are completely determined by the single-layer ceramic substrate. Generally, firstly, the position of the cavity and the size of each dimension of the single-layer ceramic substrate are pre-designed acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com