Braking system of electric skateboard

An electric scooter and brake system technology, which is applied in the field of brake systems, can solve problems such as reducing service life, affecting riding safety, and wheel wear, and achieves the effects of low manufacturing cost, simple structure, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

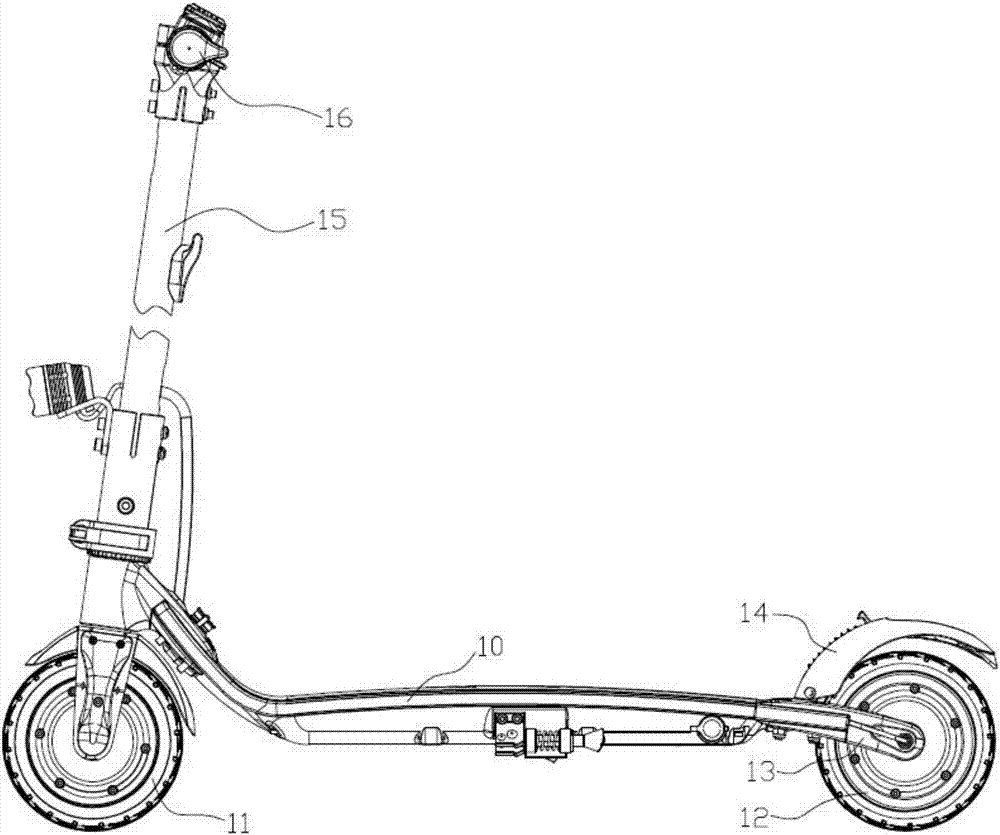

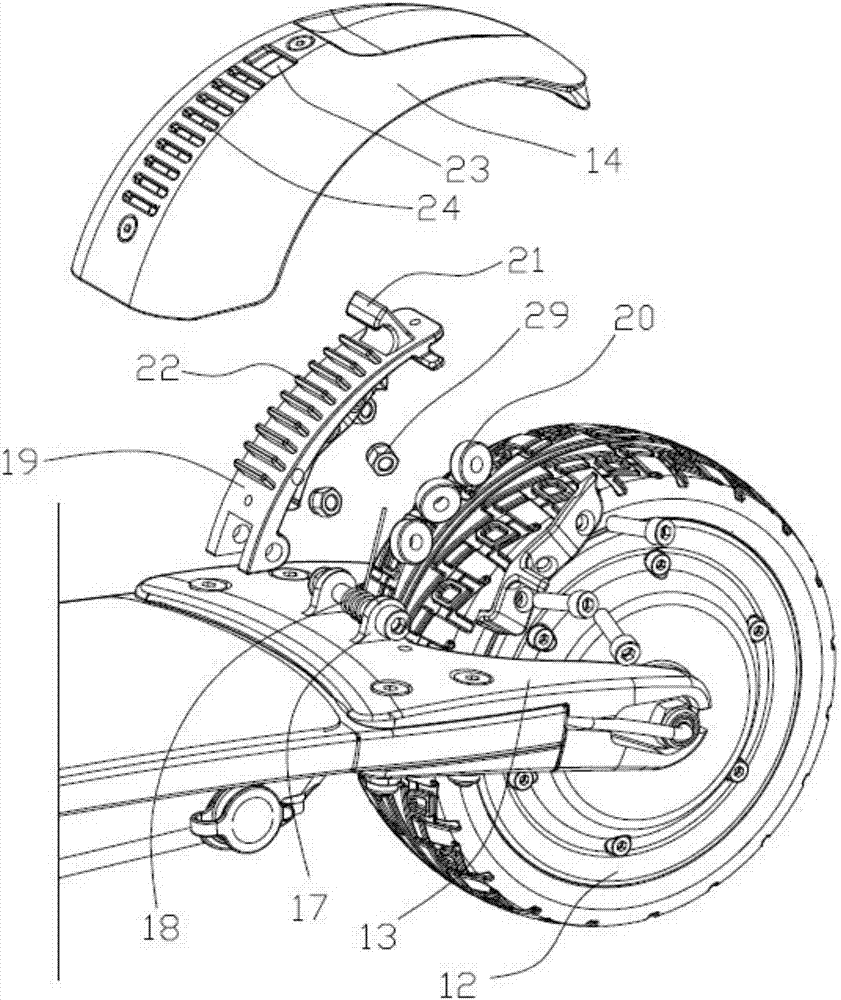

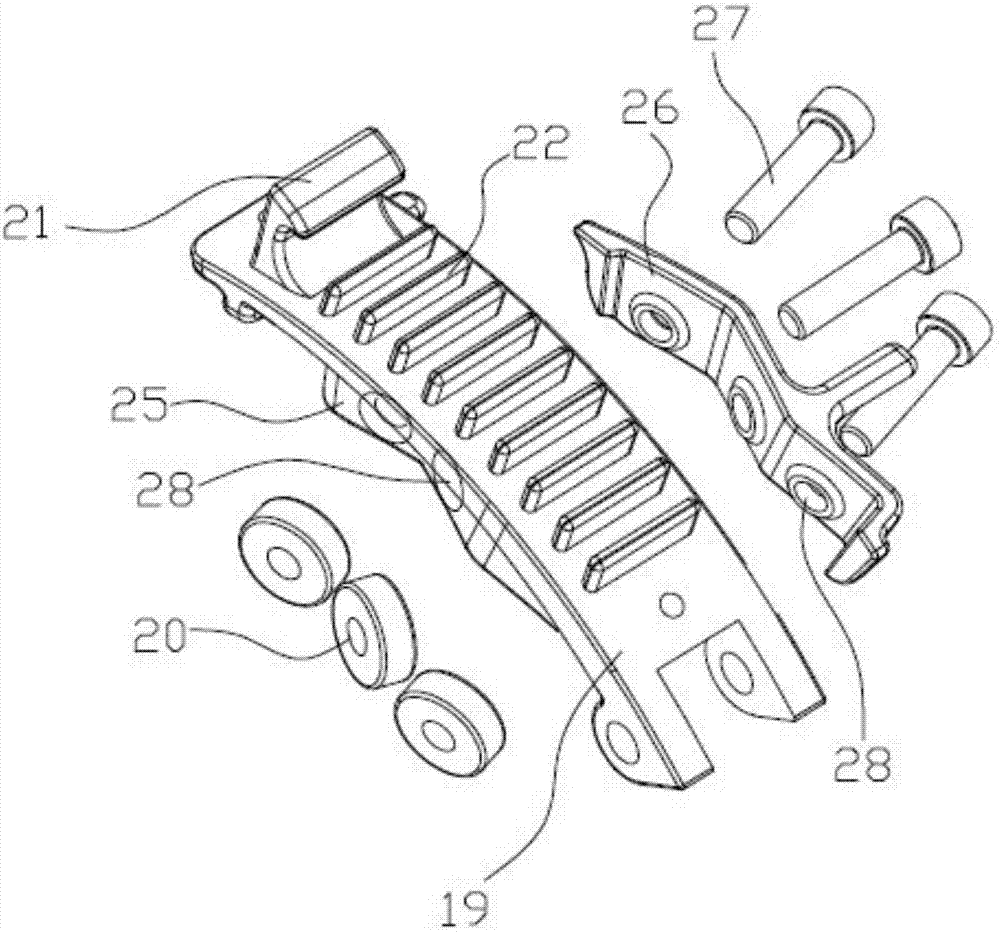

[0019] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —5: The overall structure of the electric scooter in the present invention includes a vehicle frame 10, a front wheel 11, a rear wheel 12, a rear fork 13, a pull rod 15 and a handlebar 16, and the pull rod 15 has telescopic and folding functions. The accelerator pedal is arranged on the handlebar 16, and the braking device is concentrated on the rear wheel 12. The specific structure is that the rear wheel 12 is installed on the rear fork 13, and the rear fork 13 is provided with a connecting seat 17, and the connection Seat 17 is provided with brake plate 19, and brake plate 19 acts on the surface of rear wheel 12, is provided with torsion spring 18 in described connection seat 17, and described torsion spring 18 acts on brake plate 19, can make brake plate 19 Reset under the situation of not braking, leave rear wheel 12 surface, the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com