A magnetic desulfurizer for fuel oil based on supramolecular interaction

A desulfurizer and supramolecular technology, applied in the fields of refining hydrocarbon oil, treating hydrocarbon oil, petroleum industry, etc., can solve the problem of low activity of surface hydroxyl groups, and achieve the effects of easy operation, optimized interaction, and unique design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Magnetic desulfurizer A for fuel oil is composed of β-cyclodextrin modified by divalent copper ion coordination, coupling agent 3-aminopropyltrimethoxysiloxane and ferric oxide nanospheres wrapped by carrier silica , wherein the mass fraction of β-cyclodextrin modified by divalent copper ions accounts for 0.1% of the carrier, and the mass fraction of the coupling agent 3-aminopropyltrimethoxysiloxane accounts for 1% of the carrier. Synthesis steps: ferric iron tetroxide nanospheres (referred to as APTS-SiO 2 @Fe 3 o 4 ) and β-cyclodextrin (referred to as Cu(II)-β-CD) modified by divalent copper ions in N-methylpyrrolidone, where APTS-SiO 2 @Fe 3 o 4 The mass ratio of the total mass of Cu(II)-β-CD to N-methylpyrrolidone is 0.01:1, react at 80°C for 6 hours, magnetically separate, wash with ethanol, and vacuum dry to constant weight to obtain fuel oil Product magnetic desulfurizer A.

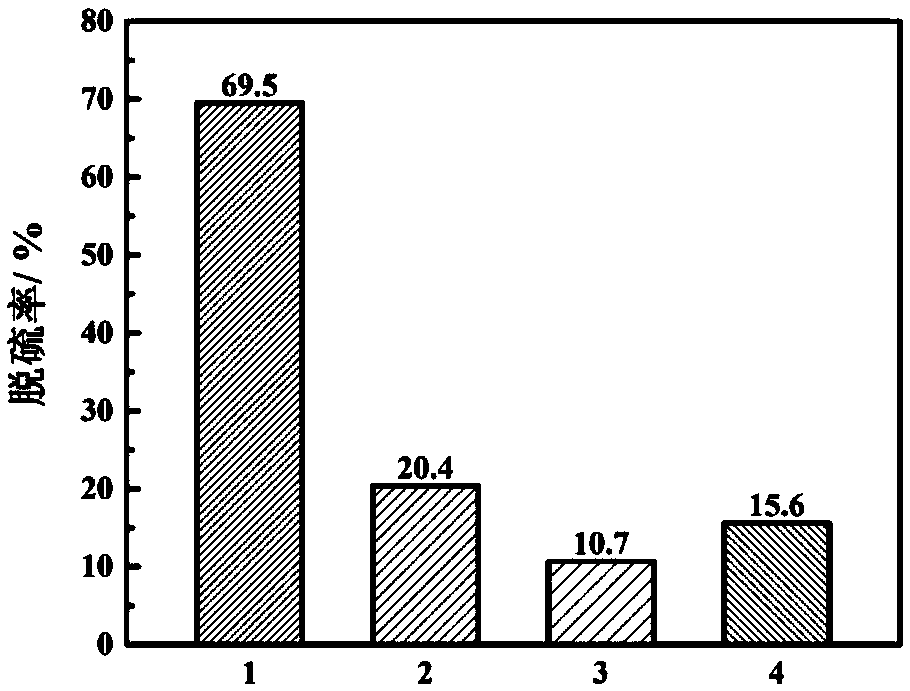

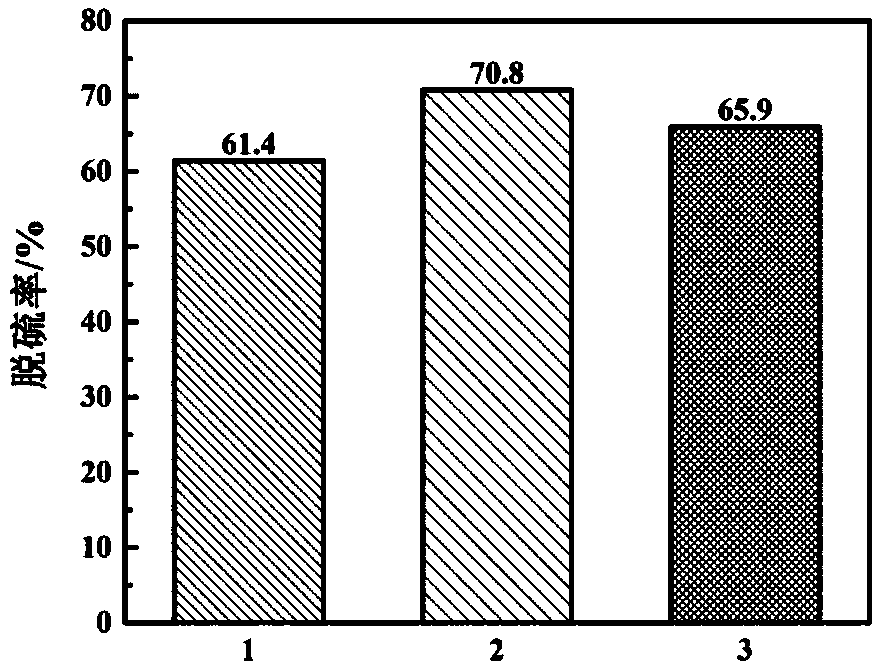

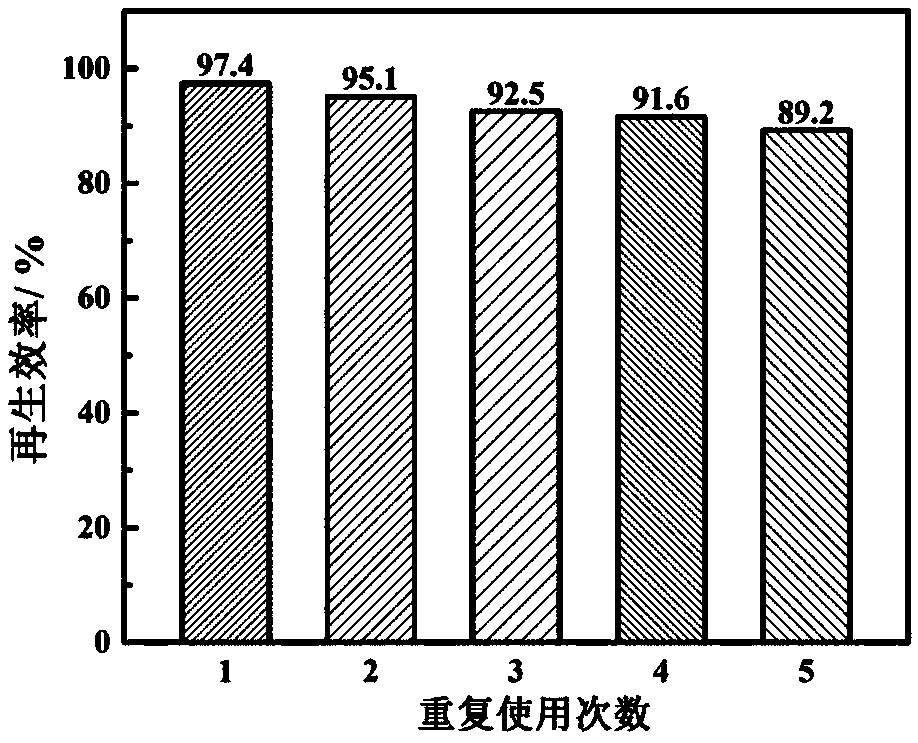

[0023] Desulfurize the desulfurizer A and the oil containing light thiophene sulf...

Embodiment 2

[0025] Fuel oil magnetic desulfurizer B is composed of β-cyclodextrin modified by divalent copper ion coordination, coupling agent 3-aminopropyltrimethoxysiloxane and ferric oxide nanospheres wrapped by carrier silica , wherein the mass fraction of β-cyclodextrin modified by divalent copper ions accounts for 1% of the carrier, and the mass fraction of the coupling agent 3-aminopropyltrimethoxysiloxane accounts for 2% of the carrier. Synthesis steps: ferric iron tetroxide nanospheres (referred to as APTS-SiO 2 @Fe 3 o 4 ) and β-cyclodextrin (referred to as Cu(II)-β-CD) modified by divalent copper ions in N-methylpyrrolidone, where APTS-SiO 2 @Fe 3 o 4The mass ratio of the total mass of Cu(II)-β-CD to N-methylpyrrolidone is 0.02:1, react at 100°C for 12 hours, magnetically separate, wash with ethanol, and vacuum dry to constant weight to obtain fuel oil Product magnetic desulfurizer B.

[0026] Desulfurize the desulfurizer B and the oil containing light thiophene sulfides ...

Embodiment 3

[0028] The fuel oil magnetic desulfurizer C is composed of β-cyclodextrin modified by divalent copper ions, coupling agent 3-aminopropyltriethoxysiloxane and ferric oxide nanospheres wrapped by carrier silica Composition, wherein the mass fraction of β-cyclodextrin modified by divalent copper ions accounts for 3% of the carrier, and the mass fraction of the coupling agent 3-aminopropyltriethoxysiloxane accounts for 3% of the carrier. Synthesis steps: ferric iron tetroxide nanospheres (referred to as APTS-SiO 2 @Fe 3 o 4 ) and β-cyclodextrin (referred to as Cu(II)-β-CD) modified by divalent copper ions in N-methylpyrrolidone, where APTS-SiO 2 @Fe 3 o 4 The mass ratio of the total mass of Cu(II)-β-CD to N-methylpyrrolidone is 0.05:1, react at 90°C for 8 hours, magnetically separate, wash with ethanol, and vacuum dry to constant weight to obtain fuel oil Product magnetic desulfurizer C.

[0029] Desulfurize the desulfurizer C and the oil containing light thiophene sulfides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com