Anti-seismic vibration isolation method and anti-seismic vibration isolation device for electromechanical equipment

A kind of electromechanical equipment and vibration isolation technology, applied in the direction of earthquake prevention, building components, etc., can solve the problems of structure vibration damage, vibration interference, equipment functional paralysis, etc., to achieve the effect of resisting the impact of earthquakes and isolating vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described below in conjunction with accompanying drawing and embodiment:

[0027] In the description of the present invention, the terms "first" and "second" are only used for descriptive purposes, and cannot be understood as indicating or implying relative importance or implicitly specifying the quantity of indicated technical features.

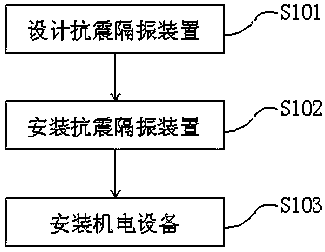

[0028] Such as figure 1 As shown, a method for anti-seismic vibration isolation of electromechanical equipment includes:

[0029] Step S101, designing an anti-seismic vibration isolation device, specifically: designing an anti-seismic vibration isolation device according to the weight of the electromechanical equipment, the natural frequency of the electromechanical equipment, and the seismic fortification requirements of the area where the electromechanical equipment is located;

[0030] Step S102, installing the anti-seismic vibration isolation device, specifically: installing the anti-seismic vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com