A Fast and Stable Method for Thickness Detection of Devices with Sub-pixel Precision

A sub-pixel-level, device-thick technology, applied in the fields of industrial vision and automatic inspection, can solve problems affecting corporate profits, reducing production capacity, and high complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

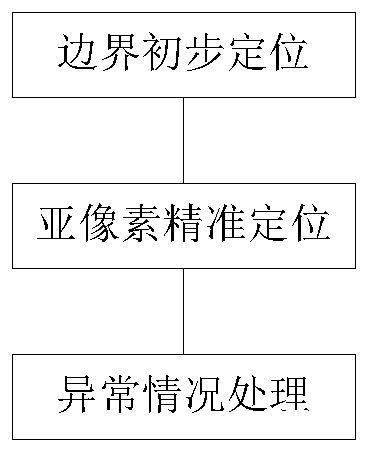

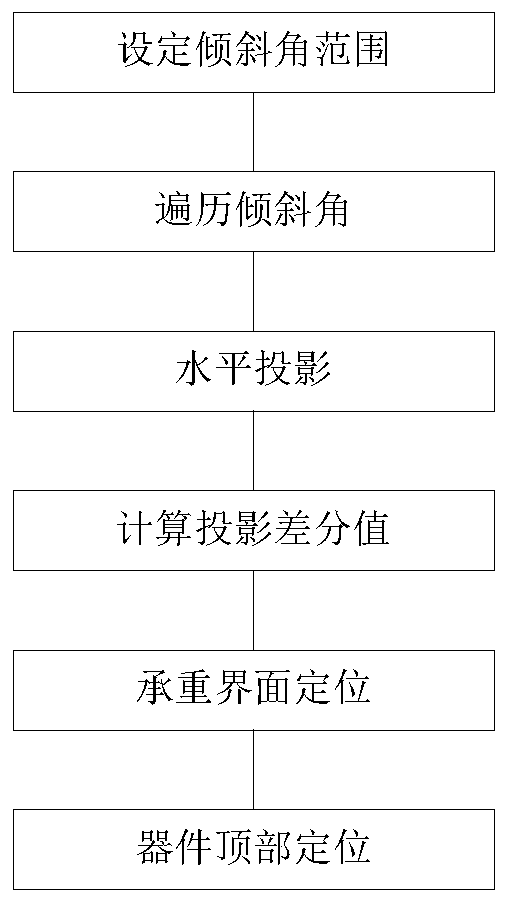

[0094] Referring to the accompanying drawings, the abnormal situations handled by the present invention include: no device in the field of view, multiple devices in the field of view, overlapping devices, gaps between the device and the glass surface, interference from dust on the device, and inaccurate placement of devices caused by tail flicking. Improve the sub-pixel boundary positioning algorithm, from the three aspects of initial positioning, parameter estimation, and fast search for the best parameters. On the basis of ensuring that the positioning accuracy meets the requirements, the algorithm speed is further improved, thereby improving the sub-pixel Potential applications of boundary localization algorithms.

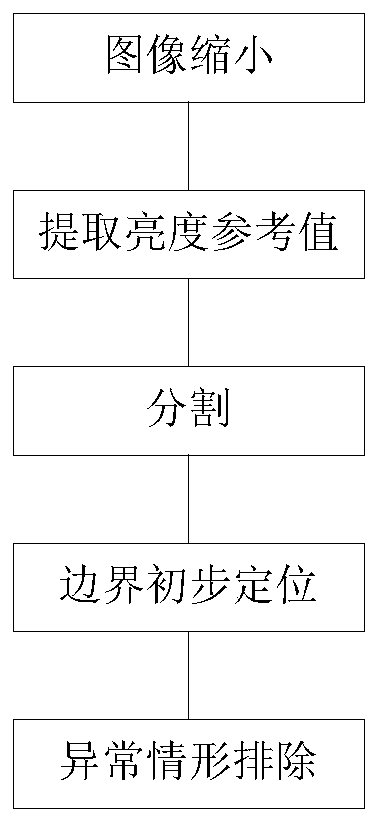

[0095] 1. Preliminary positioning of the boundary

[0096] Divide the image into two regions, target and air, and then get the dividing line of these two regions as the preliminary boundary positioning result. In this way, the subsequent precise positioning at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com