Device for automatically measuring T12 type iron core thermocouple coefficient and application method thereof

A technology of automatic measurement and soldering iron core, applied in the direction of non-electric variable control, control/adjustment system, instrument, etc., can solve the problems of single function, inaccurate temperature measurement, etc., achieve simple operation, compact shape, and avoid overheating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

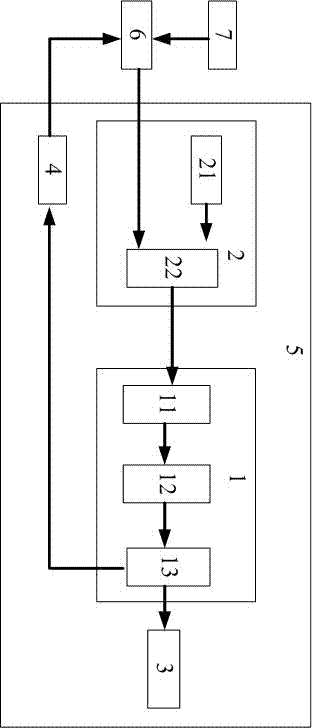

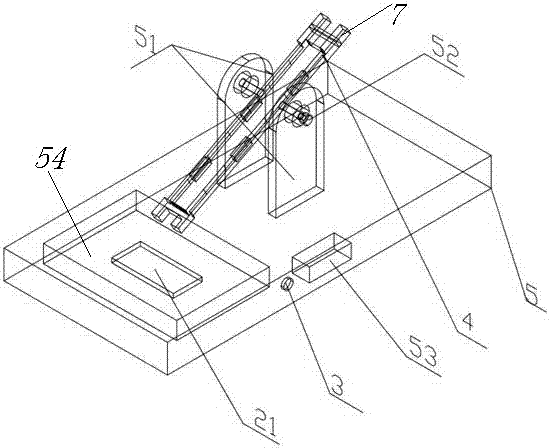

[0027] A device for automatically measuring the thermocouple coefficient in a T12-type soldering iron core, the device includes a control module 1, a temperature acquisition module 2, an alarm module 3, a temperature control module 4, an instrument shell 5, and a soldering iron for fixing the T12-type soldering iron core 6 Core support7.

[0028] The control module 1 includes an input interface 11 , a microprocessor 12 and an output interface 13 , and the temperature acquisition module 2 includes a K-type standard thermocouple 21 and a high-precision analog-to-digital conversion module 22 . K-type standard thermocouple 21, T12 type soldering iron core 22 are connected with high-precision analog-to-digital conversion module 22, the input end of microprocessor 12 is connected with high-precision analog-to-digital conversion module 22 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com