Single-phase switched reluctance motor capable of alternating operation through adoption of direct current motor principle and reluctance motor principle

A switched reluctance motor, alternating operation technology, applied in electrical components, electromechanical devices, etc., can solve the problems of single-phase SR motor without self-starting, short driving reluctance torque area, low utilization rate, etc., to improve power Density and operating efficiency, reducing torque ripple, realizing the effect of energy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

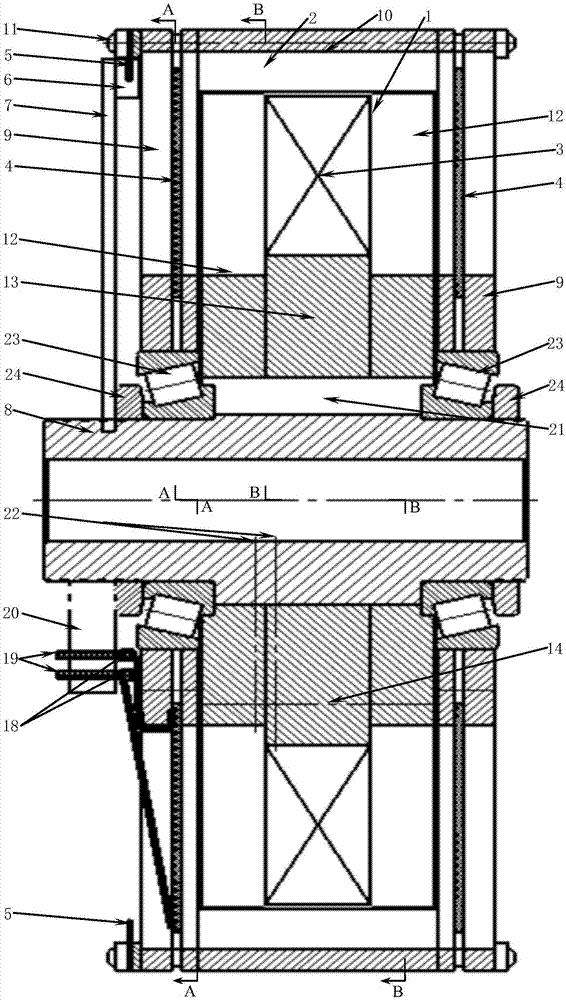

[0021] Its embodiment will be further described below in conjunction with accompanying drawing.

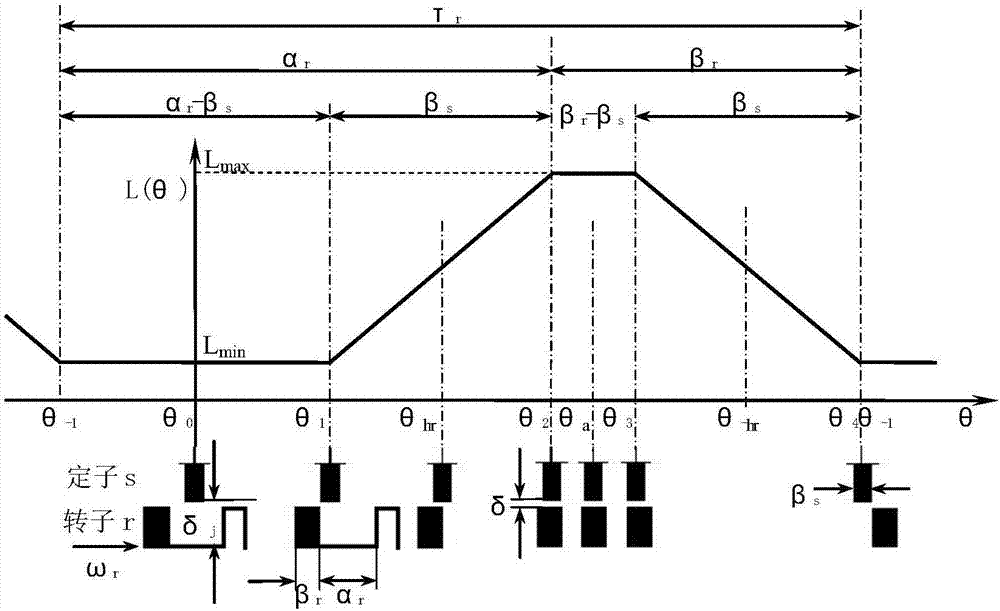

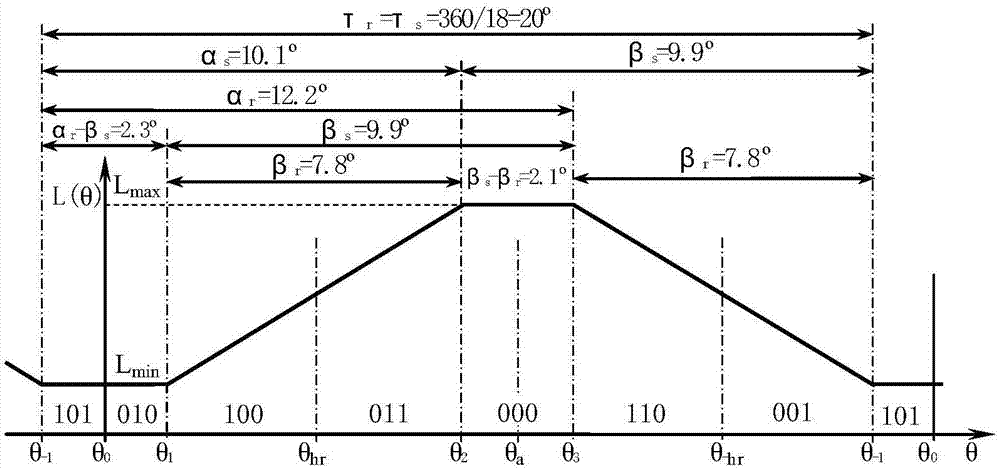

[0022] refer to Figure 2 ~ Figure 6 , a single-phase SR motor that uses two motor principles of DC and reluctance to operate alternately, and needs to use the attached figure 1 The relationship between the linear inductance L of the SR motor and the rotor displacement angle θ is shown, and the characteristic point area where the motor operates according to the two principles of DC and reluctance is analyzed, so as to adjust the number of stator and rotor poles and the salient pole distance. Structural parameters, to expand the operating area that can generate driving torque according to the two motor principles, and improve various related operating performances. In order for the stator to be excited, all the salient poles of the stator and rotor act on each other, and the number of poles or pole pitch angles of the stator and rotor are required to be equal; in order to improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com