Preparation method of negative pressure type canned seasoned tomato blocks

A tomato block, negative pressure technology, applied in the field of food seasoning, can solve the problems of lack of high value-added canned tomato block products, low added value, etc., to shorten the sterilization time, enhance the affinity, and prevent the secondary separation of water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

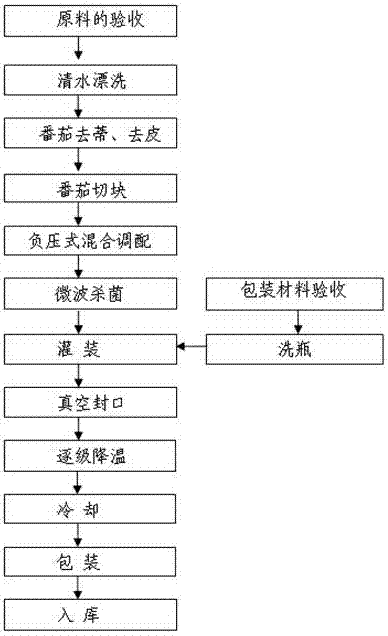

[0015] The present invention will be further described below in conjunction with accompanying drawing:

[0016] 1) Acceptance of tomato raw materials: select tomatoes that are naturally mature in summer fields, have natural contours, regular shapes, and bright red color, and remove green fruits, tomatoes with black spots, rotten fruits and foreign impurities;

[0017] 2) Tomato destemming and peeling: Rinse the selected tomatoes with clean water until they meet the hygienic standards required for processing, manually remove the tomato stalks, and then quickly pass the tomatoes through the steam room with a conveyor belt, and then spray them with cold water quickly. The drum peeling machine can peel whole tomatoes for use;

[0018] 3) Preparation of tomato pieces: pass the peeled whole tomato through a vegetable cutter, and cut into pieces with a size of about 3cm*3cm*3cm;

[0019] 4) Negative pressure mixing and blending: low-pressure, low-temperature concentration and blendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com