Battery sorting method

A battery and sorting technology, which is applied in sorting and other directions, can solve problems such as limitations, inconsistencies that cannot be eliminated, battery cycle life attenuation, etc., to achieve efficient power supply, increase cycle life and charge and discharge performance, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

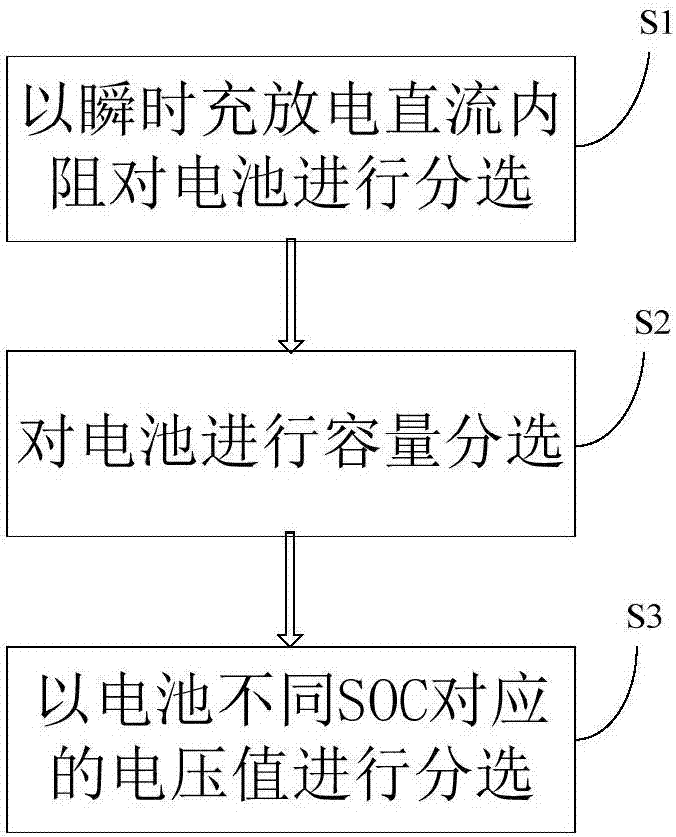

Method used

Image

Examples

specific Embodiment 1

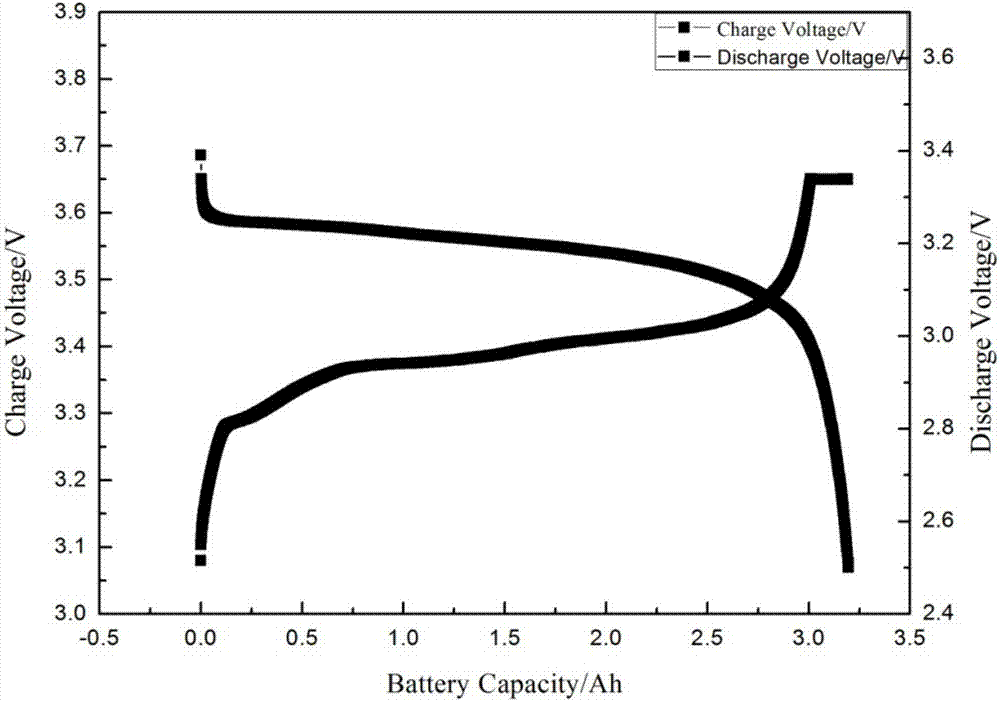

[0082] Hereinafter, one hundred 26650 lithium iron phosphate batteries with a rated capacity of 3Ah and a nominal voltage of 3.2V are taken as an example to introduce the battery sorting method of the present invention.

[0083] (1) Calculate the instantaneous charging DC internal resistance and instantaneous discharge DC internal resistance of the battery to be sorted, and use the instantaneous charging voltage in the first recording point of the last charging state in a batch of battery charge and discharge cycle data as U 1 , The charging current is set to I 1 , The voltage of the last recording point of the previous shelving state is set to U 0 , Then the instantaneous DC internal resistance R of the battery in this SOC state 1 =(U 1 -U 0 ) / I 1 ; Similarly, the instantaneous discharge voltage in the first recording point of the last discharge state is set to U 2 , The discharge current is set to I 2 , The voltage of the last recording point of the previous shelving state is set...

specific Embodiment 2

[0104] The following uses a 25Ah lithium iron phosphate battery with a rated capacity of 25Ah and a nominal voltage of 3.2V as an example to introduce the battery sorting method of the present invention.

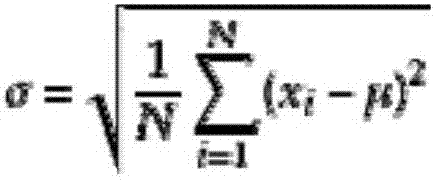

[0105] (1) The battery is sorted for the instantaneous charge and discharge DC internal resistance, and the method for calculating the instantaneous charge and discharge DC internal resistance is the same as that of Embodiment 1. After that, the instantaneous charging and discharging instantaneous resistance data of each batch of batteries in the same state are summarized, and the instantaneous charging DC internal resistance of each battery is divided by the instantaneous discharging DC internal resistance, and the quotient is greater than 1 into a group, namely Batteries with instantaneous charging DC internal resistance greater than instantaneous discharging DC internal resistance are divided into one group; other batteries are divided into another group, as shown in Table 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com