Novel copper-based infrared paint

An infrared coating, copper-based technology, applied in the coating and other directions, can solve the problems of inconvenient adjustment and high price of infrared coating, and achieve the effect of low cost, changing infrared emissivity, high emissivity and emissivity modulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

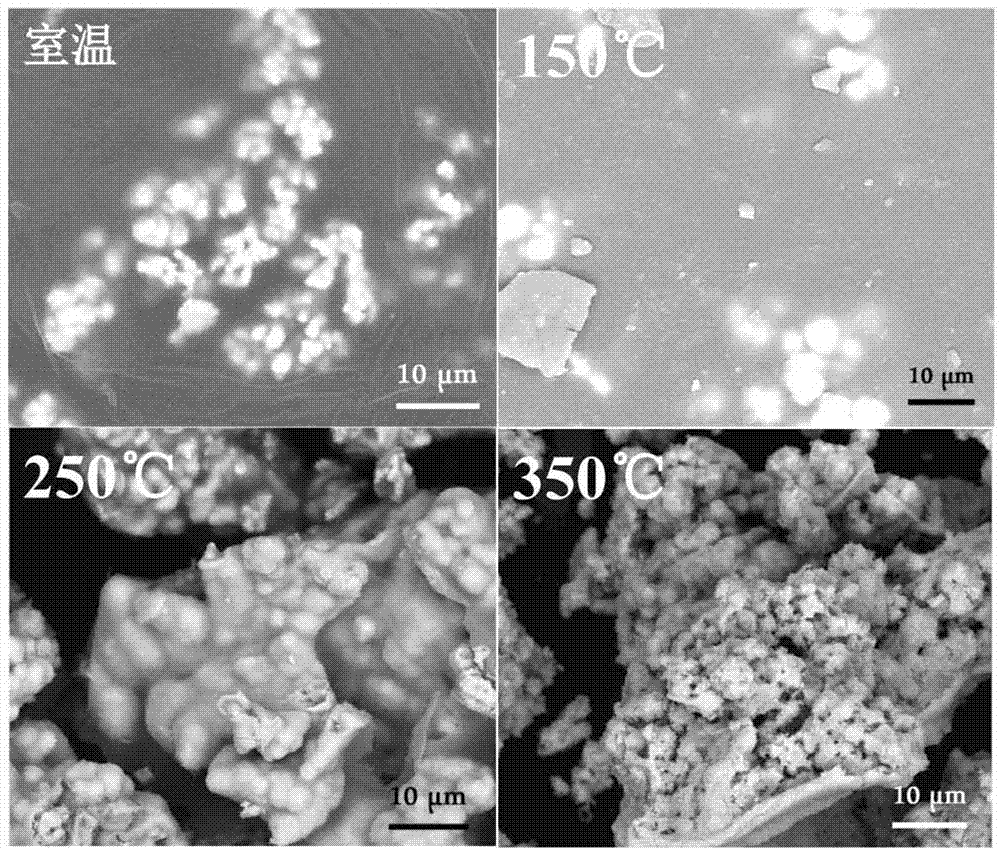

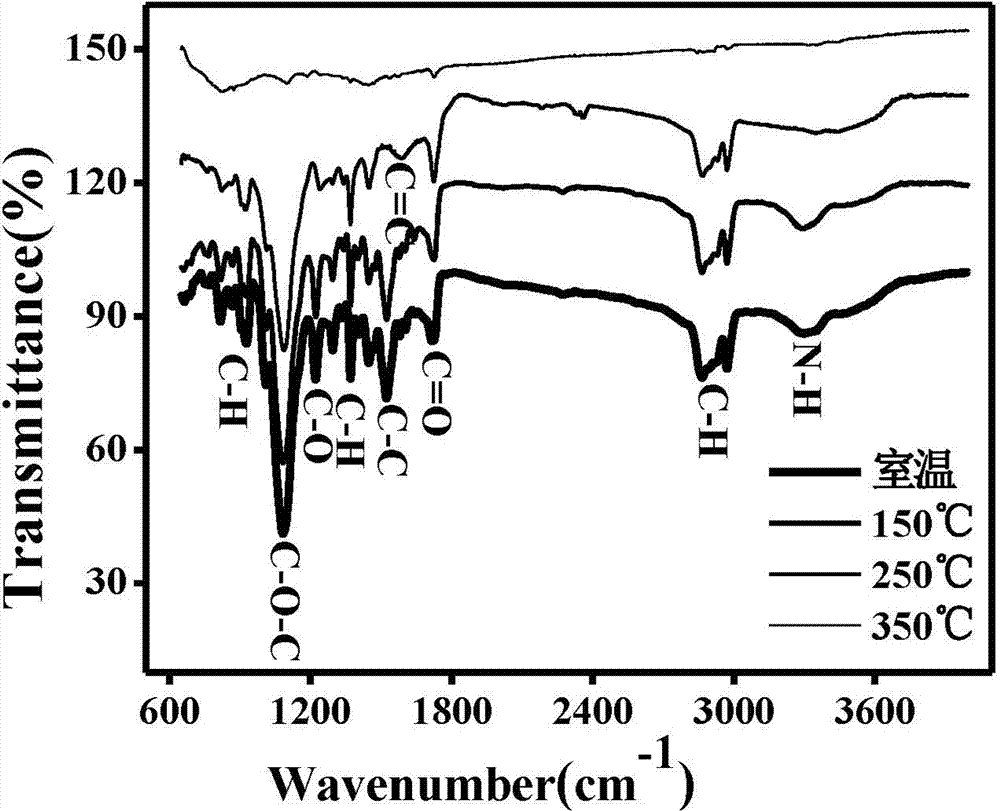

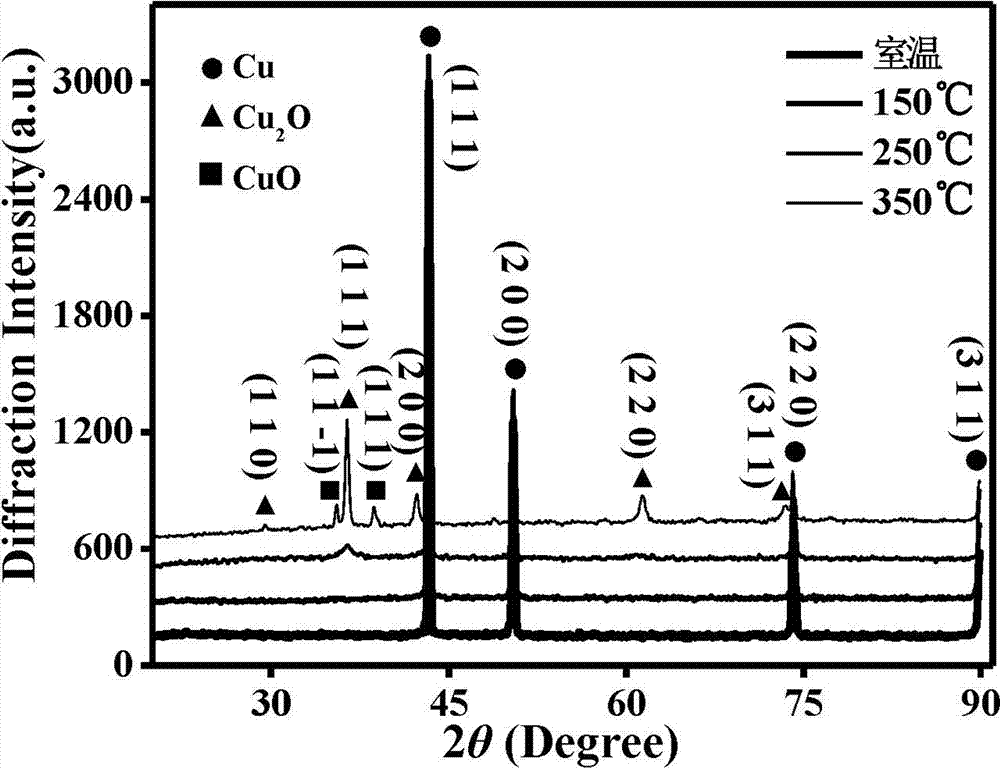

[0020] Embodiment 1: A new type of copper-based infrared coating, through heat treatment, the compound in the coating is carbonized and metal oxidized, so as to change the infrared emissivity of the coating. The coating includes polyurethane AB material, copper powder and butyl acetate After mixing, it is prepared by the following steps:

[0021] 1) Take 30 parts by mass of copper powder, 10 parts by mass of component A of polyurethane AB material, and 10 parts by mass of component B of polyurethane AB material, put in 15 parts by mass of butyl acetate, mix and stir evenly;

[0022] 2) Take the mixed solution obtained in step 1), apply it evenly on the aluminum sheet with a pad pen to form a coating, and cure it at room temperature for 24 hours;

[0023] 3) Heat the coating after solidification in step 2) for 1 hour, and the new copper-based infrared coating can be obtained after the coating returns to room temperature.

[0024] The heating temperature in step 3) is 150°C, 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com