Rough yarn pulling-type feeding-controllable spinning device

A drawing type, roving technology, applied in the field of spinning, can solve the problems of poor evenness of yarn, inability to adjust the main draft freely, and low cost of transformation, and achieves increased variety, convenient and controllable feeding, improved The effect of the overall quality of the yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

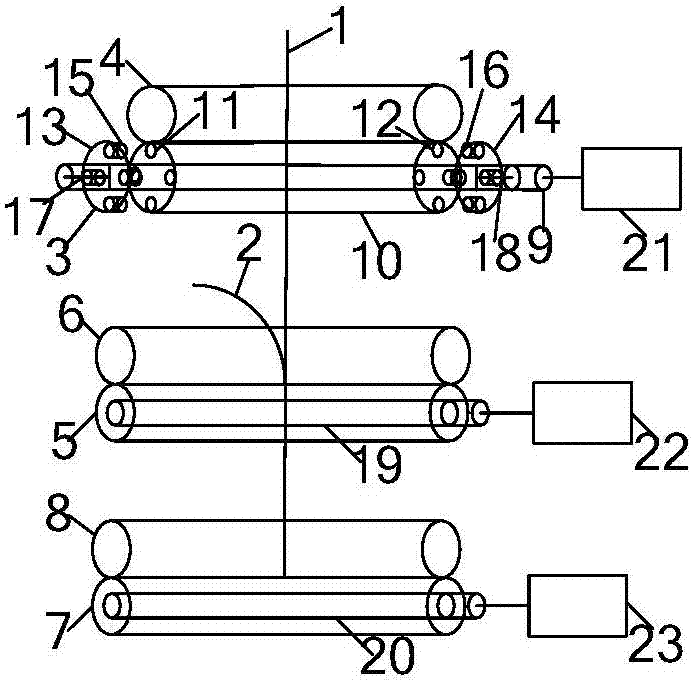

[0009] Depend on figure 1 As shown, a roving pull-type controllable feeding spinning device includes a rear draft roller pair composed of a rear roller 3 and a rear rubber roller 4, and a middle draft roller composed of a middle roller 5 and a middle rubber roller 6. Pair, the front drafting roller pair consisting of the front roller 7 and the front rubber roller 8, the middle roller includes the middle roller shaft 19, the middle roller shaft is a solid cylinder, and the middle roller sleeve is fixedly connected to the middle roller shaft, and the front roller Including the front roller shaft 20, the front roller shaft is a solid cylinder, the front roller shaft is fixedly connected with a front roller sleeve, the rear roller includes a rear roller shaft 9, the rear roller shaft is a solid cylindrical shape with smooth surface, and the rear roller shaft A back roller cover 10 is installed on the top, and the back roller cover is a steel circular ring with a smooth inner surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com