Wall bushing prefabricated block-based wall bushing construction method

A technology of wall-piercing sleeves and construction methods, applied in the direction of pipes/pipe joints/fittings, pipes, building components, etc., can solve the problems of large loss of masonry materials, difficult construction, slow construction speed, etc., and reduce labor costs , Reduce the construction process and reduce the loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Such as figure 1 Shown, the present invention comprises the following steps:

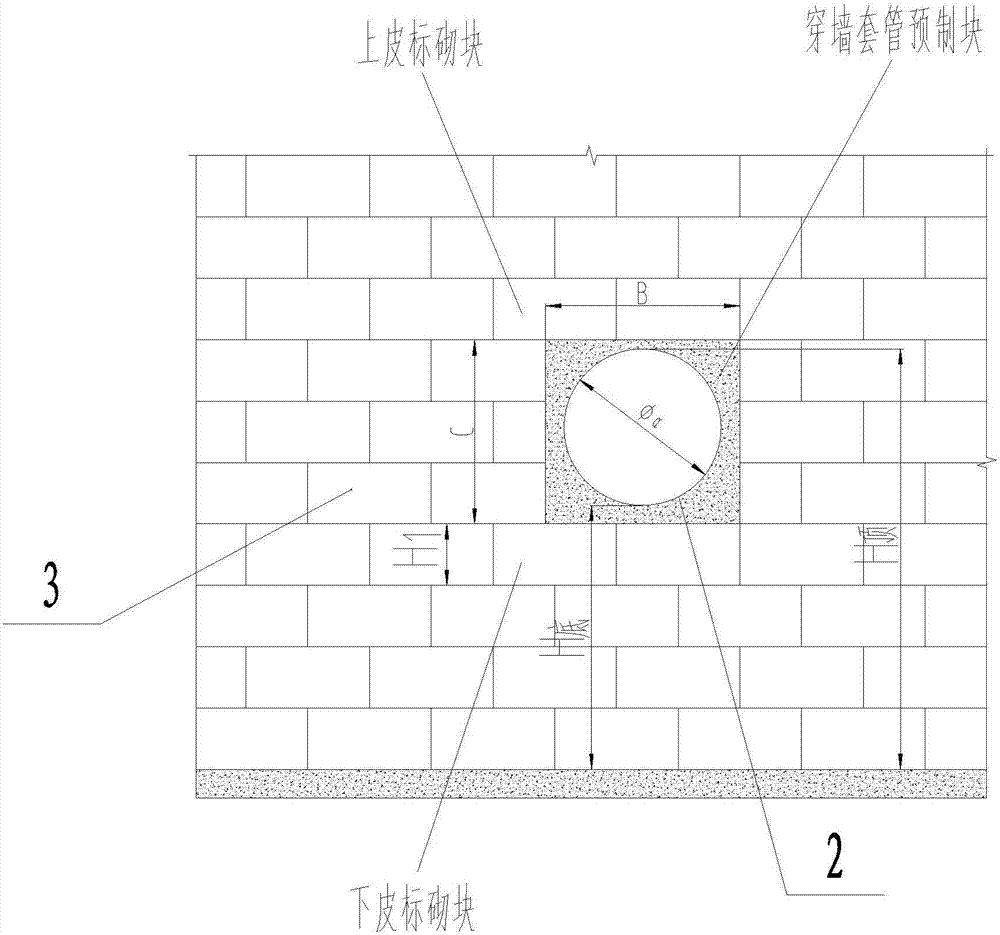

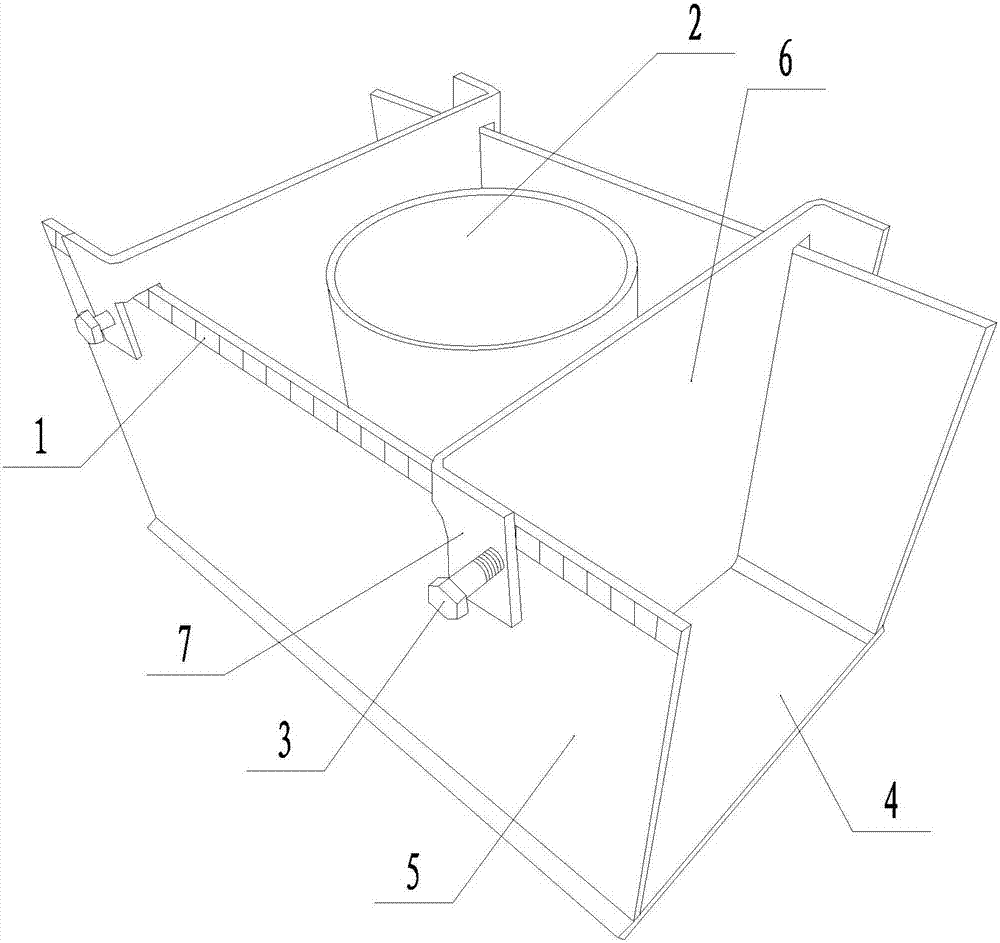

[0038]Step 1. Construction preparation: calculate the size of the prefabricated block of the through-wall casing and determine the elevation of the bottom of the prefabricated block of the through-wall casing; the prefabricated block of the through-wall casing is a cubic concrete block, and the constructed through-wall casing In the concrete block; the length A, width B and height C of the prefabricated block of the wall casing are determined respectively, A=1.2α~1.5α, α is the diameter of the wall casing 2, and B is equal to the The thickness of the construction wall, the wall to be constructed is a wall formed by masonry blocks and passed through by the wall sleeve 2; C=α+ΔH 顶 +ΔH 底 ,in

[0039]

[0040]

[0041] Among them, H 1 is the thickness of the block; H 2 is the thickness of the mortar joint of the wall to be constructed; H 顶 is the top elevation of wall casing 2, H 底 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com