Water heater having power generation system and water heater power generation method

A technology for power generation systems and water heaters, which is applied in the directions of generators/motors, water heaters, fluid heaters, etc., and can solve the problems of unusable water heaters and user inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

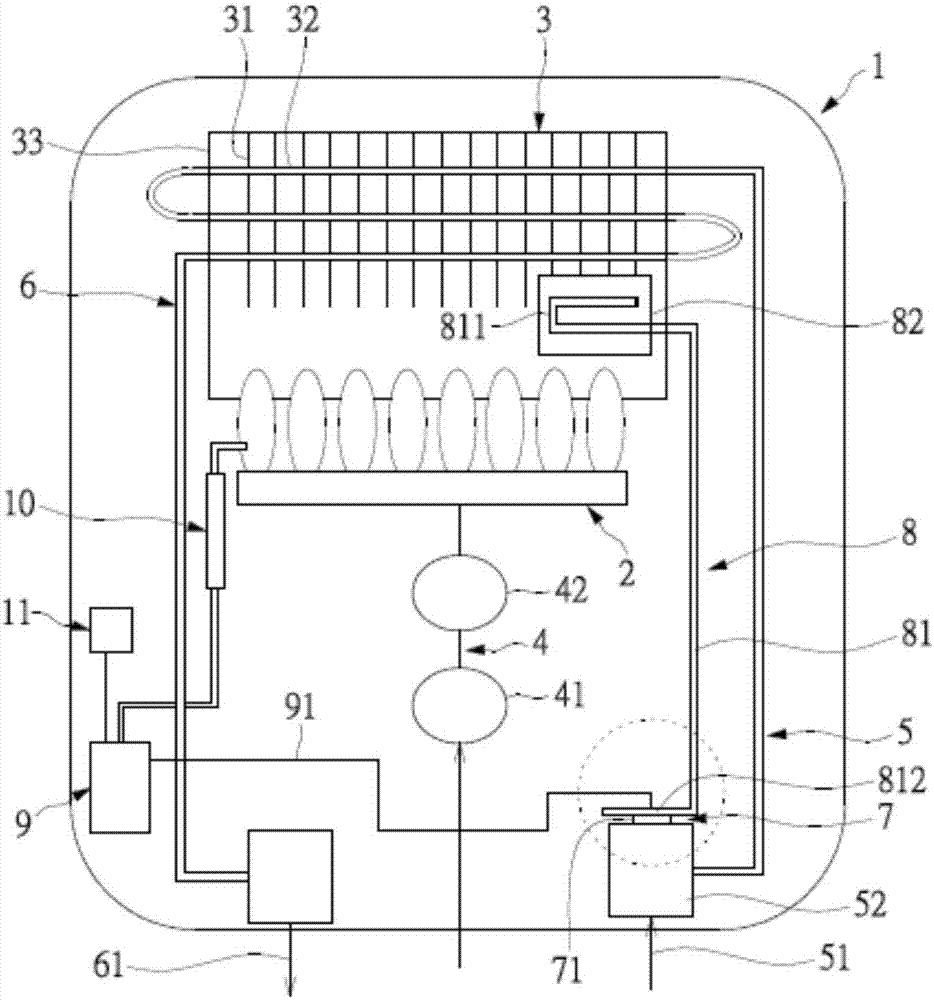

[0027] see figure 1 , the present invention provides a water heater with a power generation system, the water heater is a gas water heater, including a body 1, a burner (fire row) 2 and a heat exchanger 3. The body 1 is a hollow shell, and the burner 2 and the heat exchanger 3 are arranged inside the body 1 . The positions of the burner 2 and the heat exchanger 3 are not limited and can be changed according to needs. In this embodiment, the burner 2 and the heat exchanger 3 are sequentially arranged inside the machine body 1 from bottom to top. The burner 2 can be connected with a gas pipeline 4 , and one end of the gas pipeline 4 can be connected to a gas (gas) source for delivering gas to the burner 2 . A first solenoid valve 41 and a second solenoid valve 42 can be provided on the gas pipeline 4 to control the on-off and flow of gas. When the burner 2 is ignited, the burner 2 can generate high-temperature combustion gas, which is pushed upwards, and the combustion gas con...

no. 2 example

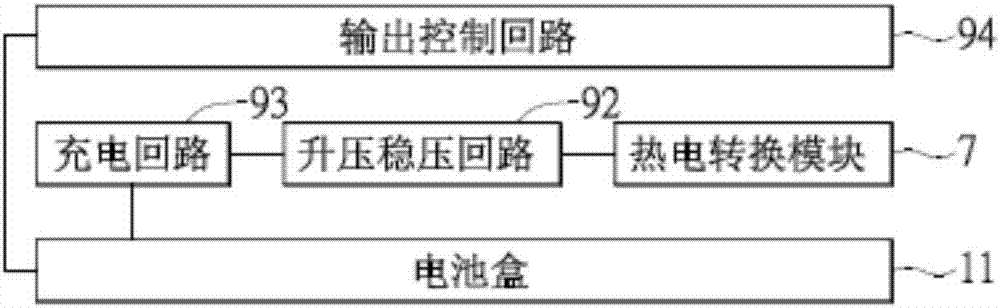

[0037] Also, see Figure 1 to Figure 4 , the power storage module 9 of the present invention may further comprise a boosting and stabilizing loop 92, a charging loop 93 and an output control loop 94, the boosting and stabilizing loop 92 is electrically connected to the thermoelectric conversion module 7, and the charging loop 93 is electrically The battery box 11 is electrically connected to the charging circuit 93 , the output control circuit 94 is electrically connected to the battery box 11 , and the battery box 11 can accommodate a rechargeable battery. Therefore, the present invention can obtain electric power through the thermoelectric conversion module 7 , and maintain the obtained electric power at a voltage that can be supplied to the rechargeable battery through the boosting and stabilizing circuit 92 . The charging circuit 93 at the rear stage can directly supply the load (such as the igniter 10 ), or recharge the remaining power after use to the battery box 11 . T...

no. 3 example

[0042] see figure 1 , figure 2 and Figure 5 , the present invention additionally provides a water heater power generation method, comprising the steps of:

[0043] First, a water heater with a power generation system is provided; since the water heater is the same as the above-mentioned embodiment, it will not be described in detail;

[0044] Then, start the water heater, so that the cold water can be heated into hot water by the water heater; when the burner 2 is ignited, the burner 2 can generate high-temperature combustion gas, which is pushed upward, and the combustion gas contacts the heat exchanger 3. The heat exchanger 3 is heated to a high temperature for heat exchange operation, whereby the water flowing through the heat exchanger 3 can be heated from normal temperature to a high temperature, and then the hot water can be discharged for use; as well as

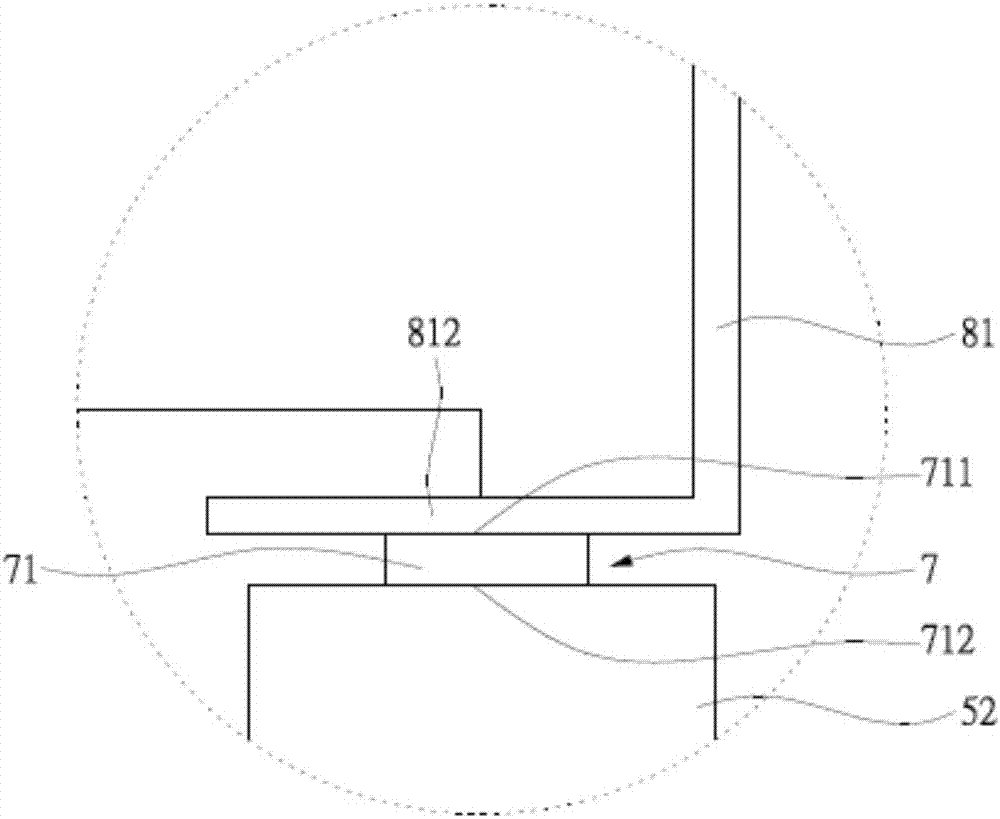

[0045] When the heat exchanger 3 is heated, the high temperature is conducted to the hot junction 711 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com