Automatic brush washer with bamboo strips clamped with soft sheets and in eccentric rotation

A technology of eccentric rotation and scrubbing machine, which is applied in application, food processing, food science, etc., can solve the problems of restricting the development of agricultural production, poor scrubbing effect, and high labor intensity, so as to reduce the input of manual labor and improve scrubbing. The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

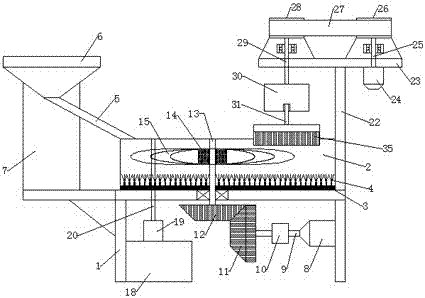

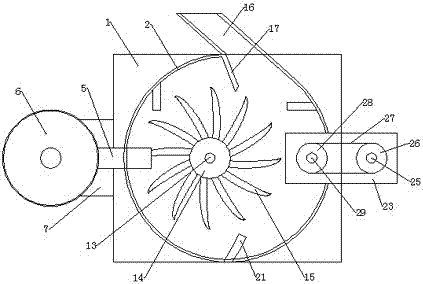

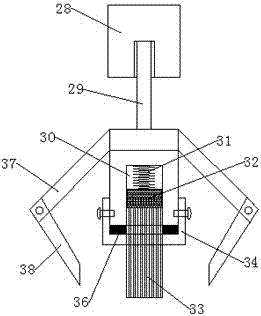

[0022] As shown in the accompanying drawings, an automatic scrubbing machine for eccentrically rotating bamboo strips with film clamping includes a frame 1, a cleaning basin 2, a bottom plate 3, a lower cleaning soft brush 4, a delivery pipe 5, a feeding hopper 6, a fixing frame 7, First motor 8, first output shaft 9, reducer 10, first bevel gear 11, second bevel gear 12, central shaft 13, turntable 14, scraper 15, discharge port 16, paddle 17, water tank 18. Water pump 19, water supply pipe 20, water outlet 21, column 22, mounting plate 23, second motor 24, second output shaft 25, driving wheel 26, belt 27, driven wheel 28, connecting shaft 29, connecting head 30 , connecting handle 31, mounting groove 32, spring 33, plug seat 34, bamboo bar 35, end cover 36, butt hole 37, rubber pad 38, connecting frame 39, flushing pipe 40, the top of described frame 1 passes bolt Or the mode of clamping is installed with cleaning basin 2, and described cleaning basin 2 is the cylindrical b...

Embodiment 2

[0025] As shown in the accompanying drawings, an automatic scrubbing machine for eccentrically rotating bamboo strips with film clamping includes a frame 1, a cleaning basin 2, a bottom plate 3, a lower cleaning soft brush 4, a delivery pipe 5, a feeding hopper 6, a fixing frame 7, First motor 8, first output shaft 9, reducer 10, first bevel gear 11, second bevel gear 12, central shaft 13, turntable 14, scraper 15, discharge port 16, paddle 17, water tank 18. Water pump 19, water supply pipe 20, water outlet 21, column 22, mounting plate 23, second motor 24, second output shaft 25, driving wheel 26, belt 27, driven wheel 28, connecting shaft 29, connecting head 30 , connecting handle 31, mounting groove 32, spring 33, plug seat 34, bamboo bar 35, end cover 36, butt hole 37, rubber pad 38, connecting frame 39, flushing pipe 40, the top of described frame 1 passes bolt Or the mode of clamping is installed with cleaning basin 2, and described cleaning basin 2 is the cylindrical b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com