Combined welding station frame

A station rack and combined technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large space occupation, cumbersome structure, and no disassembly and assembly structure of the whole frame, so as to achieve convenient The effect of moving and handling, occupying a small space, and working in a clean and orderly manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

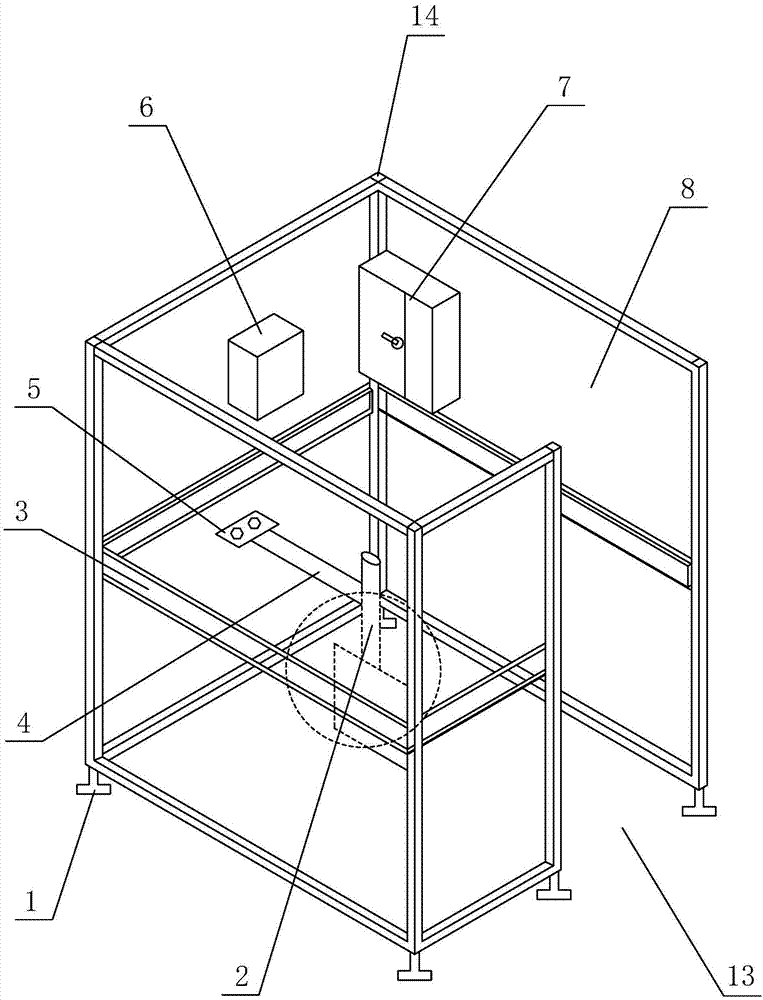

[0019] like figure 1 As shown, the combined welding station frame includes a welding operation frame and a station frame provided with a frame door 13 . The workstation frame is mainly formed by connecting four skeleton wall panels 8 in sequence, and every two adjacent skeleton wall panels 8 are connected through a detachable structure. The detachable structure includes grooves and clip strips 14 used in conjunction with the grooves, wherein the grooves are arranged on the ends of both sides of each skeleton wallboard 8 and integrally formed with the skeleton wallboard 8 . That is, when in use, the clamp strip 14 is installed at the joint of two adjacent skeleton wallboards 8 to fix the two adjacent skeleton wallboards 8 .

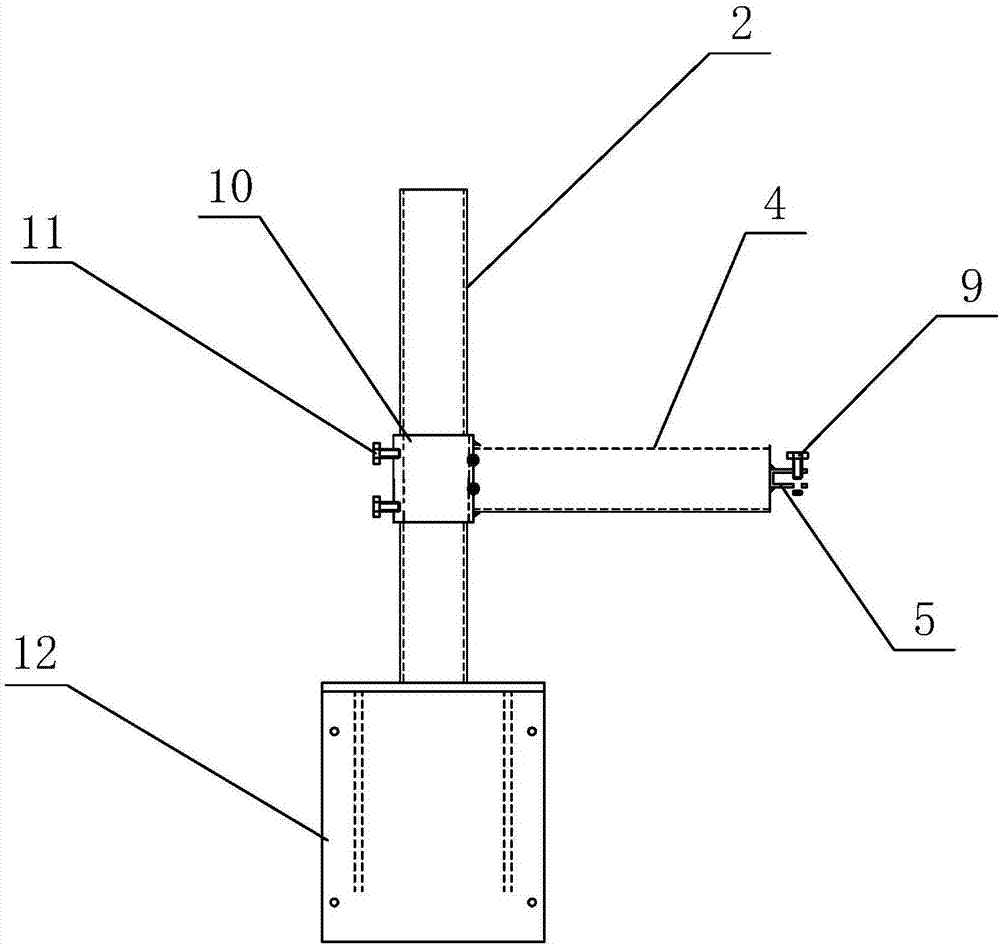

[0020] like figure 2 As shown, the welding operation frame includes a stretching cross arm 4, a connecting sleeve 10, a fixed column 2 and a connecting plate 12, and one end of the stretching cross arm 4 is provided with a specimen clamping end 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com