Hydraulic driving device

A driving device and hydraulic technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of flexible and bionic driving that cannot be applied to robots, and achieve the effect of reducing the overall structural weight, various structural designs, and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

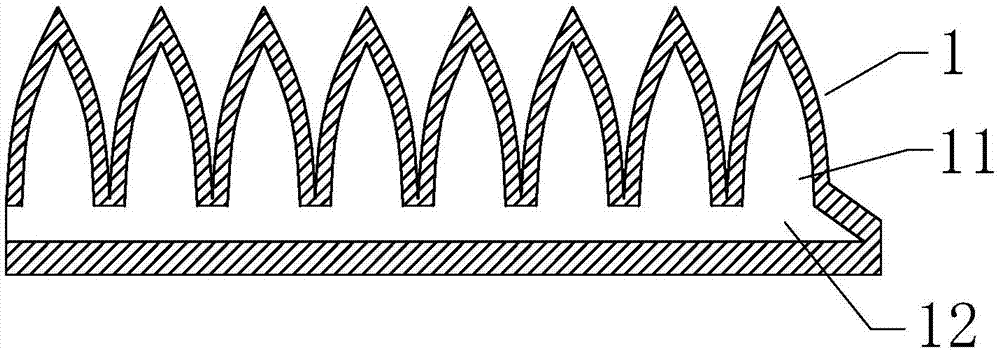

[0039] Refer to attached figure 1 , a unilateral hydraulic drive device, including a sac-shaped bending structure 1 and a hydraulic drive pump 2 arranged on one side, which changes the liquid volume in the sac cavity through the hydraulic drive system, and changes the shape of the sac cavity by the external pressure to complete actions such as rocking .

[0040] The above-mentioned sac-shaped curved structure 1 includes a liquid sac 11 and an integral through-type liquid channel 12 connecting multiple liquid sacs 11, wherein the cross-section of the liquid sac 11 is in the shape of scales, and the left end of the liquid channel 12 is the water inlet and outlet end, which is used to connect the hydraulic drive pump 2 It is used to fill or extract liquid, and the other end is sealed.

[0041] The capsule-shaped curved structure 1 is specifically made of flexible silicone material.

Embodiment 2

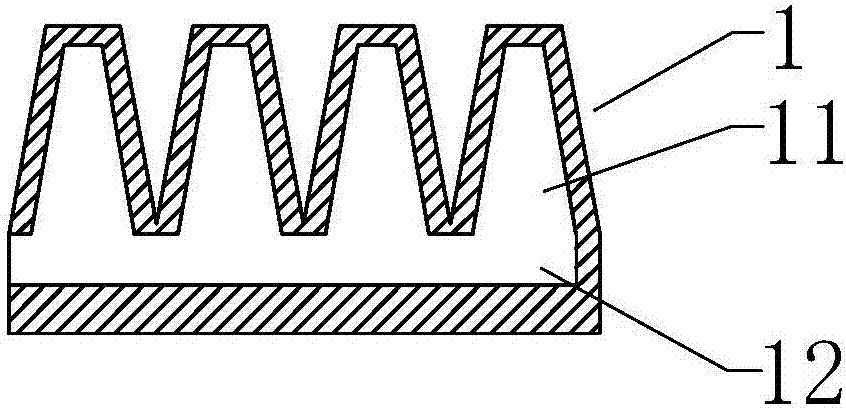

[0043] Refer to attached figure 2 , a unilateral hydraulic drive device, including a sac-shaped bending structure 1 and a hydraulic drive pump 2 arranged on one side, which changes the liquid volume in the sac cavity through the hydraulic drive system, and changes the shape of the sac cavity by the external pressure to complete actions such as rocking .

[0044] The above-mentioned sac-like curved structure 1 includes a liquid sac 11 and a liquid channel 12 connecting multiple liquid sacs 11, wherein the section of the liquid sac 11 is trapezoidal in shape, the height of the liquid sac 11 can be flexible depending on the specific situation, and the left end of the liquid channel 12 is connected to a hydraulic drive. The other end of the pump 2 is sealed, and the liquid channel 12 is closely connected with the hydraulically driven pump 2 in any manner.

Embodiment 3

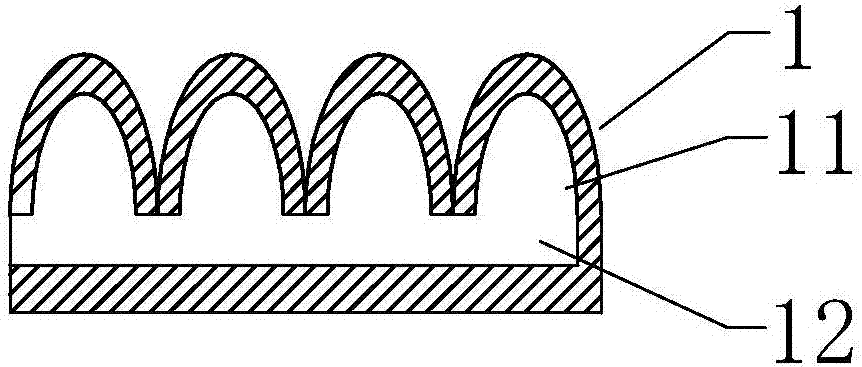

[0046] Refer to attached image 3 , a unilateral hydraulic drive device, including a bladder-like curved structure 1 and a hydraulic drive pump 2 .

[0047] The above-mentioned sac-like curved structure 1 includes a liquid sac 11 and a liquid channel 12 connecting multiple liquid sacs 11, wherein the section of the liquid sac 11 is semi-elliptical, the height of the liquid sac 11 can be flexible depending on the specific situation, and the left end of the liquid channel 12 is connected to the hydraulic pressure. The drive pump 2 is sealed at the other end, and the liquid channel 12 is tightly connected with the hydraulic drive pump 2 through threads and a rubber sealing structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com