High-cross section difference resistant high-temperature release liner and preparation process

A high-temperature release film and manufacturing process technology, applied in the direction of flat products, applications, coatings, etc., can solve the problems of high cross-section difference of soft and hard bonded boards, and achieve simplified production equipment, good lamination conformability, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

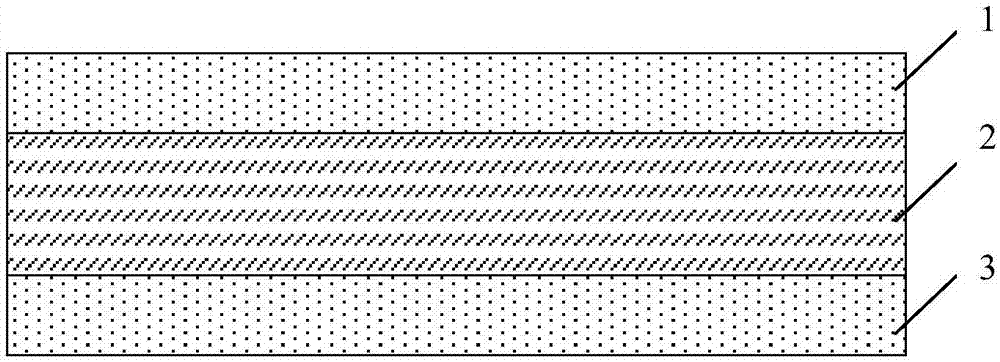

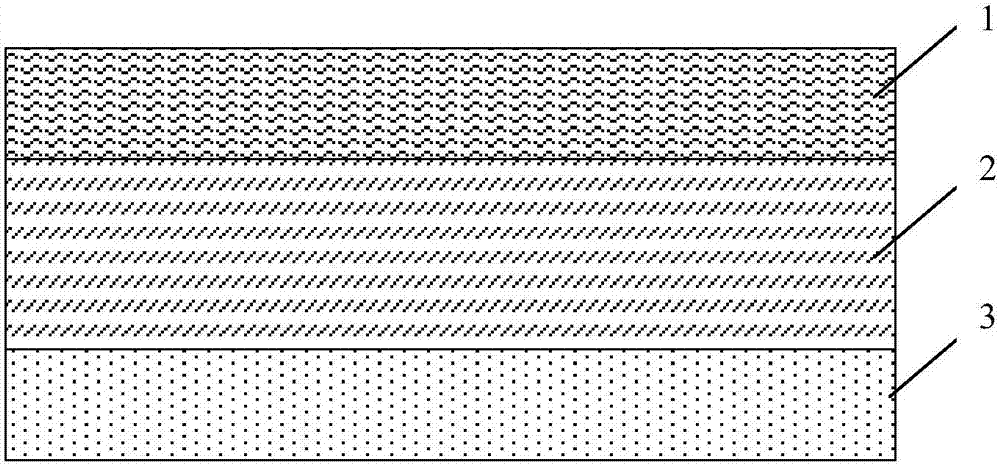

[0032] A high-temperature release film resistant to high step difference, characterized in that it includes from top to bottom: a first release layer 1, a high-extensibility support layer 2, and a second release layer 3; the first release layer 1 and the second release layer 3 are both polymethylpentene; the high-stretch support layer is nylon-modified polyolefin.

[0033] The high-temperature resistant release film is produced by a three-cavity die casting machine, and is formed at one time, with a total thickness of 20-300um.

[0034] The first release layer and the second release layer, the polymethylpentene used is one or more of Mitsui Chemicals MX004, MX002, MX002O, RT18, RT31, DX845, DX231, DX820, DX310, MBZ230, DX560M mixture; the thickness is 2-20um respectively. The above models are all Mitsui Chemicals brands, and the polymet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com