Wire winding type driving mechanism for shape memory alloy wire

A memory alloy wire and drive mechanism technology, which is applied in the direction of mechanisms, machines/engines, and mechanical equipment that generate mechanical power, can solve problems such as large space, and achieve the effects of miniaturization, reliable structure and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

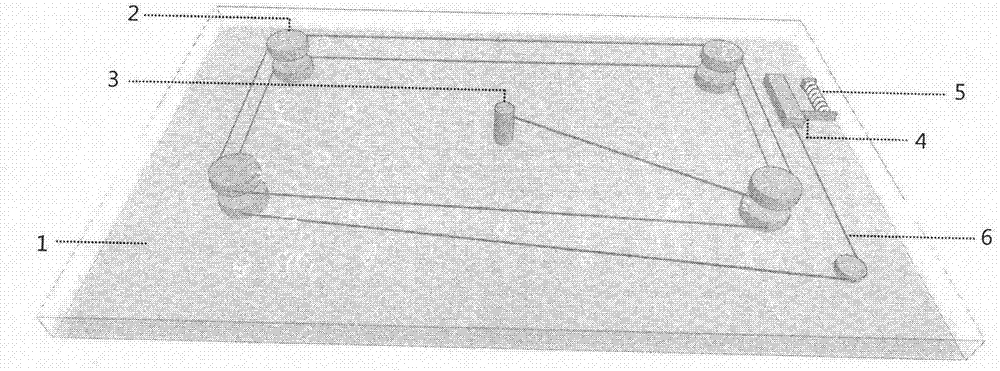

[0015] Example 1. As figure 1 shown

Embodiment 2

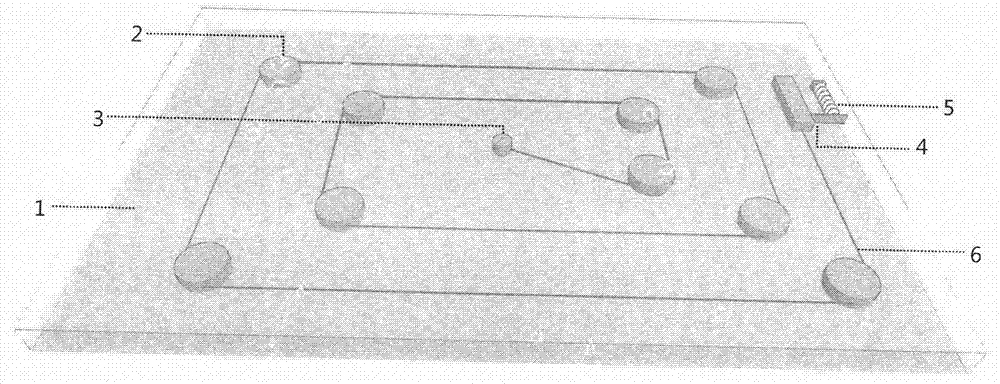

[0016] Example 2. If figure 2 shown

Embodiment 3

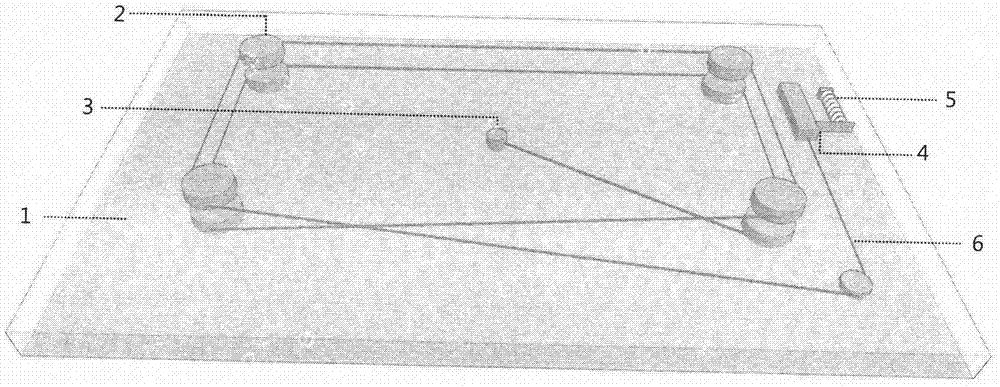

[0017] Example 3. As image 3 shown

[0018] The working process of the shape memory alloy wire winding drive mechanism is as follows:

[0019] Perform tensile pre-deformation on the shape memory alloy wire 6 and perform mechanical training.

[0020] according to figure 1 or figure 2 or image 3 As shown in the assembly, the fixed end 3 and the displacement output end 4 are connected to an external power supply, and current heating is used to restore the shape of the shape memory alloy wire.

[0021] When energized and heated, the shape memory alloy wire 6 recovers and shrinks, and the recovery displacement of the shape memory alloy wire 6 bypassing the different fold lines of the pulley 2 is well transmitted to the displacement output terminal 4 through the pulley 2 to realize displacement output.

[0022] Cut off the power supply, the shape memory alloy wire 6 is naturally cooled, and under the action of the tension spring 5, the shape memory alloy wire 6 is elongated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com