Boiler combustion system

A boiler combustion and boiler technology, which is applied in the field of boiler combustion system, can solve the problems of high cost and large energy consumption, and achieve the effects of easy ignition, improving combustion utilization rate and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described with reference to the accompanying drawings.

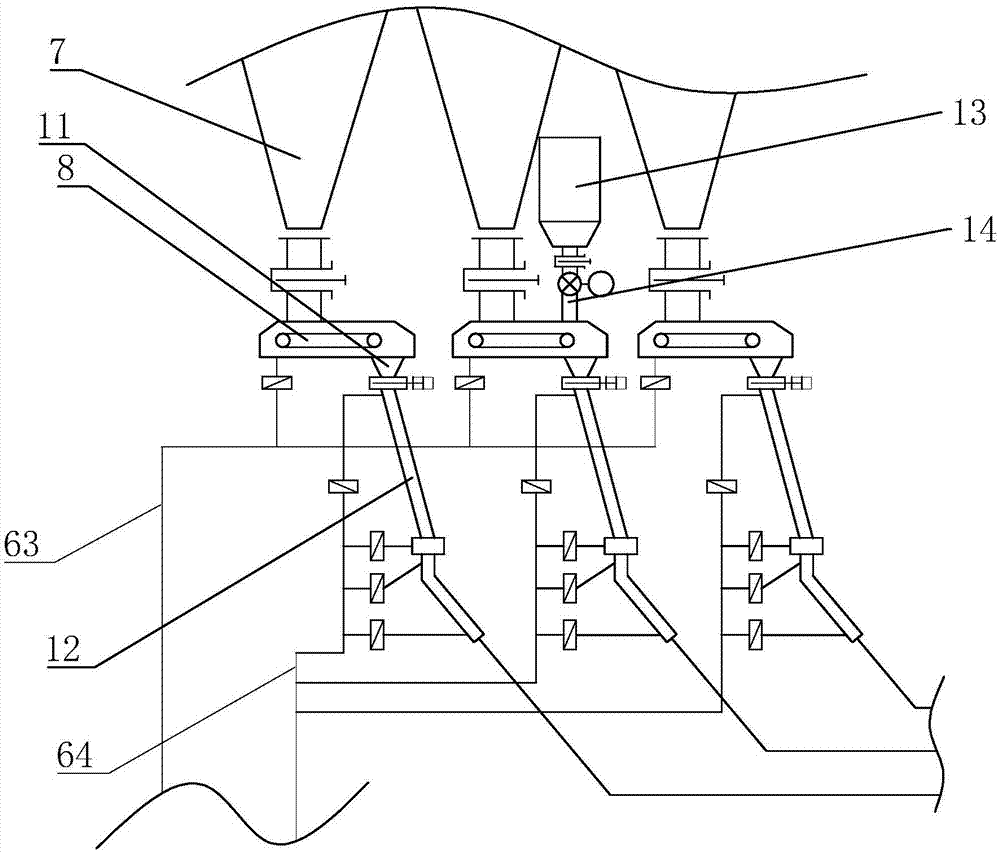

[0049] like figure 1 As shown, a boiler combustion system includes a raw coal bunker 1, a boiler 2, a cyclone separator 3, an electrostatic precipitator 4, a desulfurization device 5 and a chimney 6 in sequence.

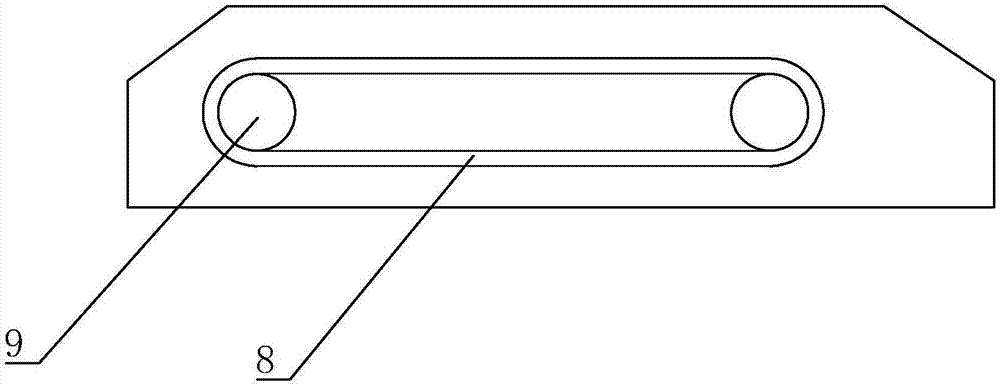

[0050] like figure 1 and figure 2 As shown, the raw coal bunker 1 is provided with several. The lower end of the raw coal bunker 1 is provided with a first discharge hopper 7, and a valve is provided at the opening of the lower end of the first discharge hopper 7. like figure 2 and image 3 As shown, the lower end of the first discharge hopper 7 is provided with a metering belt 8 and a rotating roller 9 . like image 3 and Figure 4 As shown, the metering belt 8 is sleeved outside the rotating roller 9, and there are two rotating rollers 9, which are located at both ends of the metering belt 8 respectively. One end of one of the rotating rollers 9 is coaxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com