Fixing device and fixing method for high-temperature particle irradiation sample

A fixing method and sample technology, which is applied in the use of wave/particle radiation for material analysis, measuring devices, instruments, etc., can solve the problems of low bonding strength of conductive adhesives, inability to meet the requirements of rough surface bonding, and the impact of bonding strength, etc. , to achieve the effect of overcoming the reduction of the viscosity of the conductive adhesive, avoiding the reduction of the viscosity of the conductive adhesive, and overcoming the unfavorable factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

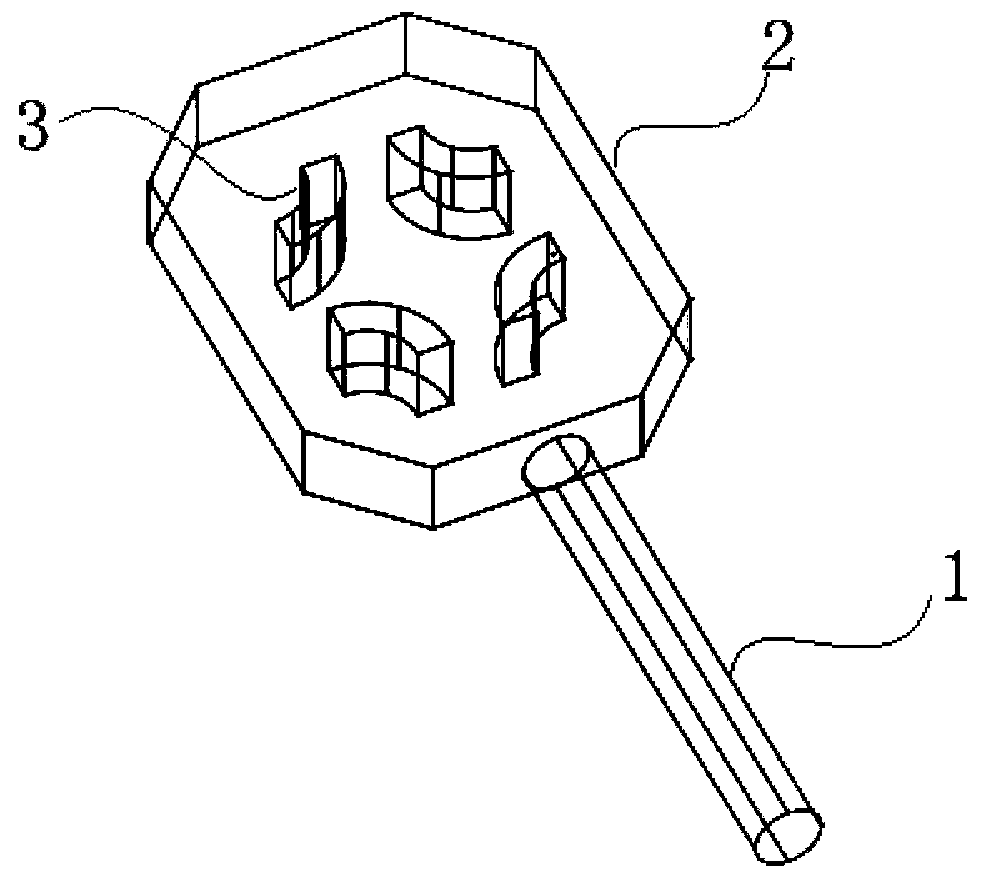

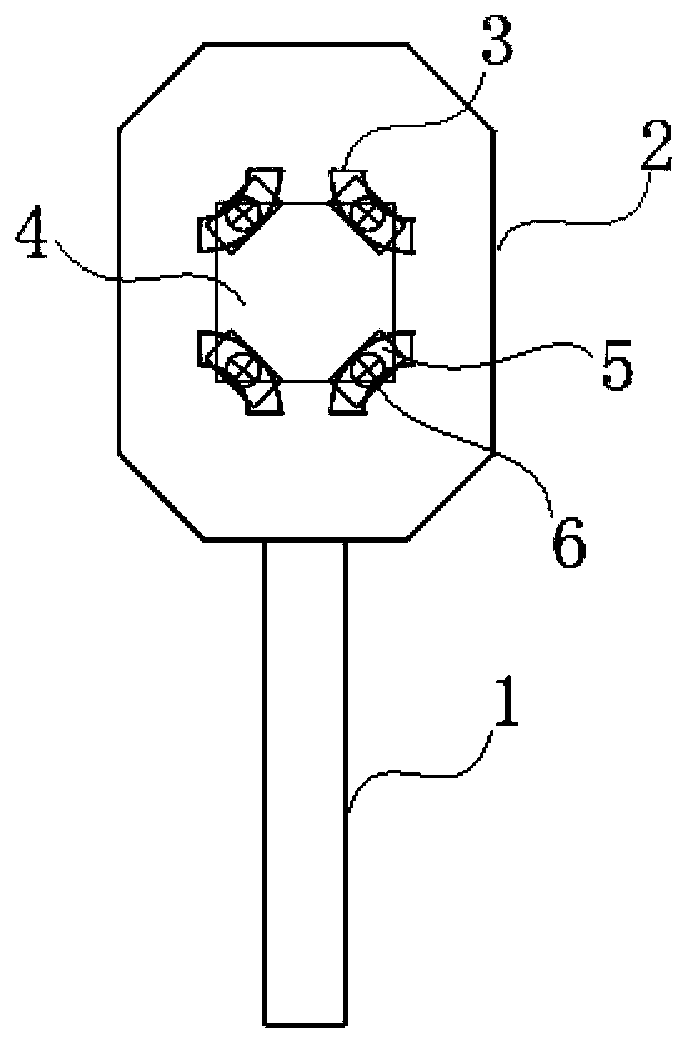

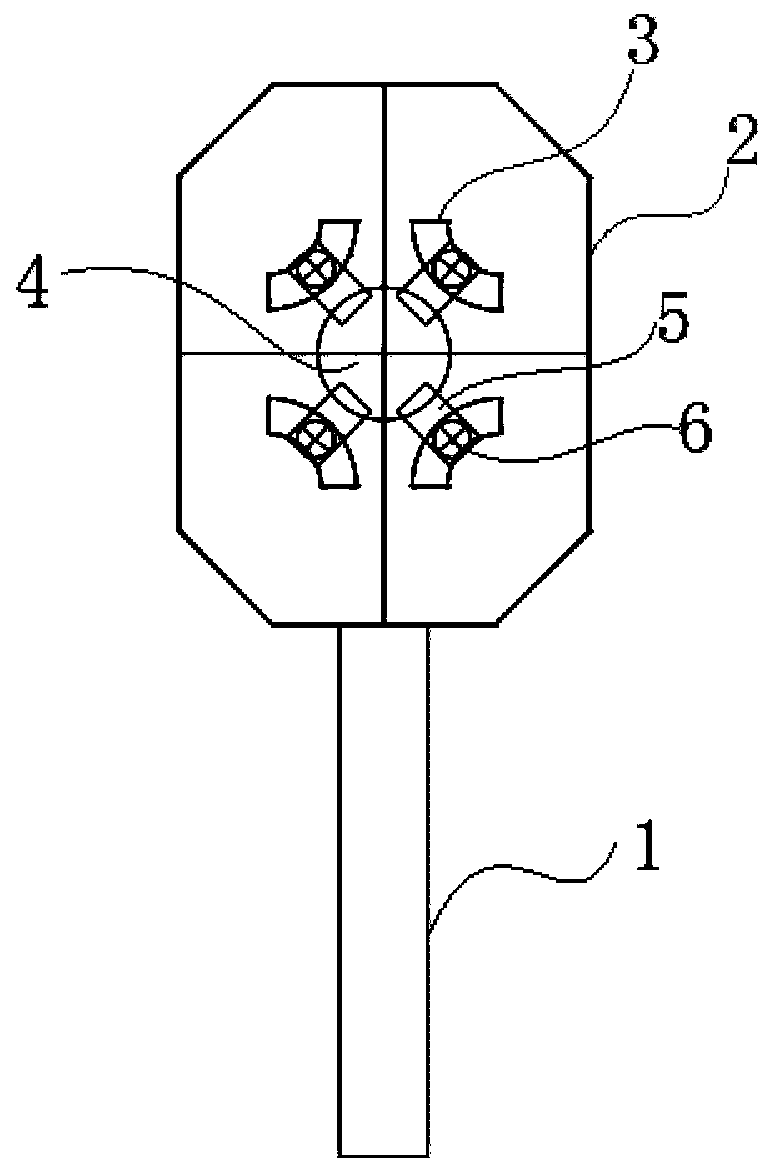

[0030] Embodiment 1: Fix the sample 4 whose size is 18mm×18mm×1mm, adopt a kind of fixing device for irradiating the sample with high-temperature particles, such as figure 1 As shown, it includes a sample holder 2 fixed in the irradiation equipment through a bracket 1, and the bracket 1 is a pillar with a diameter of 0.8 cm. The sample holder 2 is a vertical plate structure, the four corners of the sample holder 2 are polished 45° chamfers, the upper and lower ends of the sample holder 2 are 4.0 cm long, 3.5 cm high, and 0.8 cm thick. There are four arc-shaped hollow guide rails 3 symmetrical to the center of the panel on the board surface, and the radians of the guide rails 3 are bent outward away from the center of the board surface. Specifically, the width of the curved hollow guide rail 3 is 2.0 mm, and the radian is π / 2.

[0031] The arc-shaped hollow guide rail 3 is used for fixing the sample 4 through the passage of the screw 6 and matching the nut. First, the edge of...

Embodiment 2

[0038] Embodiment 2: Fix the disc sample 4 with a radius of 3.0 mm, which is roughly the same as that of Embodiment 1, except that the selected copper sheet 5 is a copper sheet 5 with a length of 8 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com