Technique for cooling a combustion engine

An internal combustion engine, cooling liquid technology, applied in the control of coolant flow, liquid cooling, engine cooling, etc., can solve the problems of increasing the heat sink, increasing the installation space, insufficient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

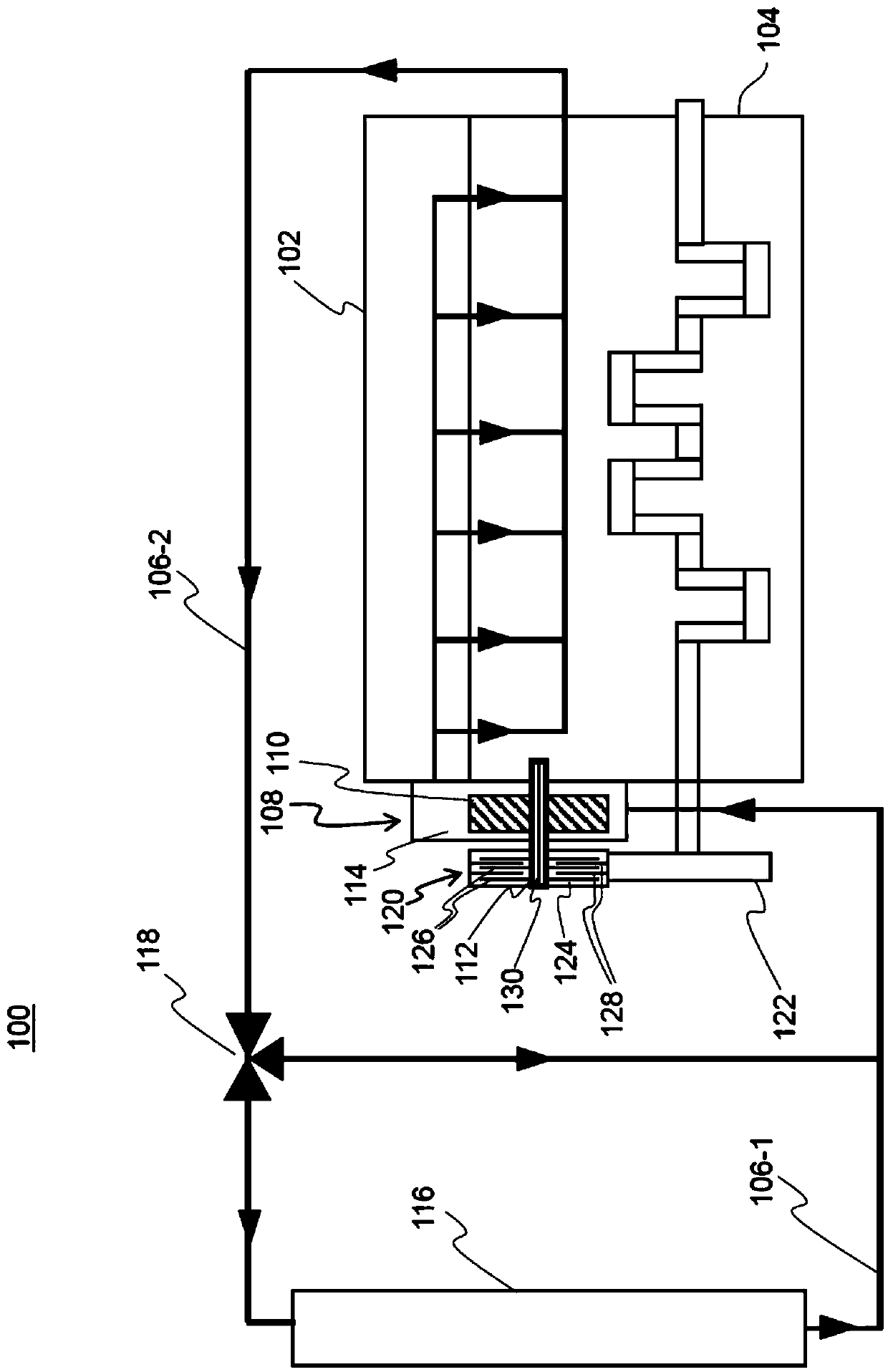

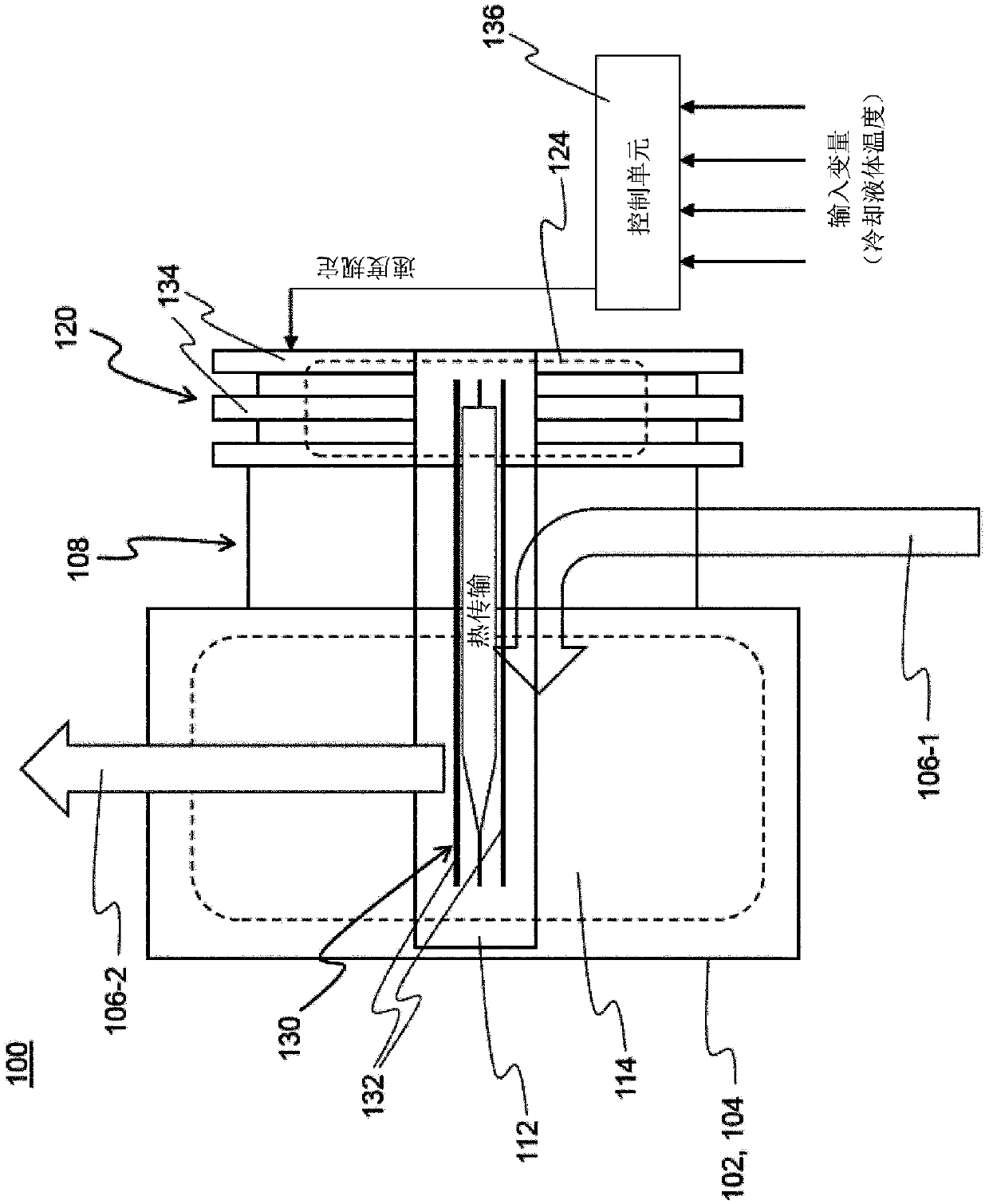

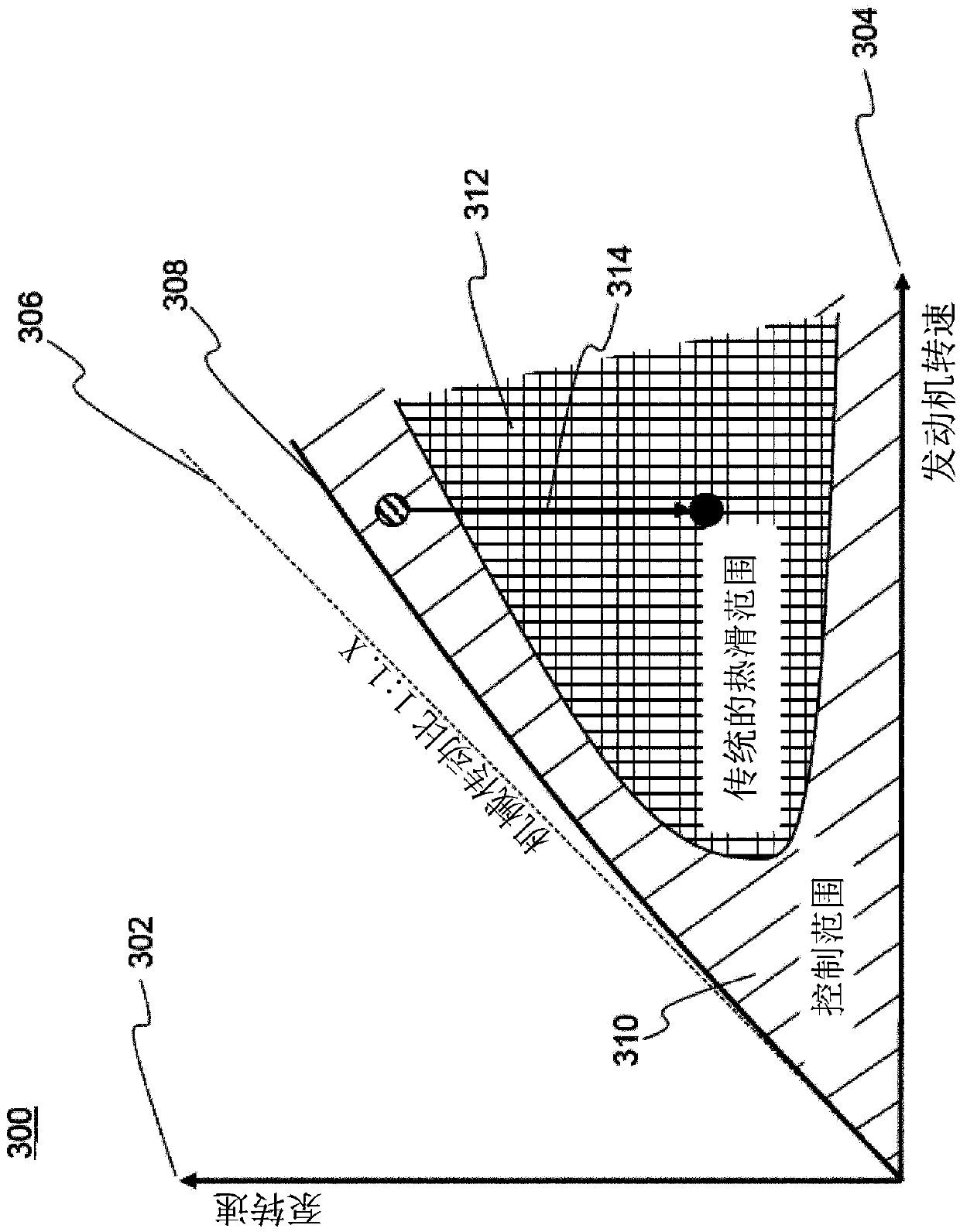

[0028] figure 1 A first embodiment of the internal combustion engine is shown generally designated by the reference numeral 100 . The internal combustion engine 100 includes a cylinder head 102 and an engine block 104 , which are connected to a cooling liquid circuit, generally designated with reference numeral 106 . Internal combustion engine 100 also includes a coolant pump 108 , which is connected on the inlet side to input 106 - 1 of coolant circuit 106 . Cooling liquid pump 108 is in fluid connection on the outlet side with cooling lines in cylinder head 102 and engine block 104 .

[0029] The cooling liquid pump 108 includes a rotating wheel 110 (such as an impeller or propeller) on a drive shaft 112 in a pump housing. The running wheel 110 and the pump-side end of the drive shaft 112 are immersed in the cooling liquid 114 of the cooling liquid circuit 106 , which fills the pump housing. The cooling liquid 114 comprises, for example, water with additives for raising t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com