A kind of preparation method of high temperature resistant composite crosslinking agent

A composite cross-linking agent and high-temperature-resistant technology, which is applied in the preparation of organic compounds, botanical equipment and methods, and the preparation of aminohydroxyl compounds, and can solve problems such as reservoir damage, fast cross-linking speed, and low applicable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

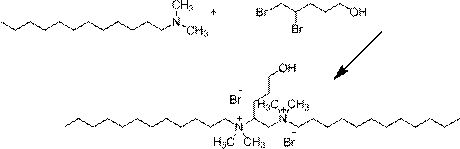

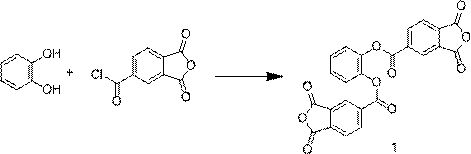

Method used

Image

Examples

Embodiment 1

[0045] A high temperature resistant composite crosslinking agent, comprising the following raw materials in parts by weight:

[0046] 20 parts of zirconium oxychloride octahydrate solution, 10 parts of sodium lauryl sulfate solution, 20 parts of cyclohexane, 15 parts of glycerol, 1.5 parts of borax and 3 parts of auxiliary additives;

[0047] The high temperature resistant composite crosslinking agent is prepared through the following steps:

[0048] Step 1: Add the zirconium oxychloride octahydrate solution dropwise into the sodium lauryl sulfate solution, set the temperature at 25°C and the rotation speed at 300r / min, stir and mix for 10min, then add cyclohexane, keep the temperature and rotation speed Continue to stir for 3 hours, add sodium hydroxide solution to adjust the pH value to 10, set the temperature to 120°C, and the rotation speed to 400r / min, and stir for 20 hours. After the reaction, wash with deionized water and absolute ethanol three times in sequence. obtai...

Embodiment 2

[0062] A high temperature resistant composite crosslinking agent, comprising the following raw materials in parts by weight:

[0063] 25 parts of zirconium oxychloride octahydrate solution, 11 parts of sodium lauryl sulfate solution, 30 parts of cyclohexane, 20 parts of glycerol, 2 parts of borax and 3.5 parts of auxiliary additives;

[0064] The high temperature resistant composite crosslinking agent is prepared through the following steps:

[0065] Step 1: Add the zirconium oxychloride octahydrate solution dropwise to the sodium lauryl sulfate solution, set the temperature at 20°C and the speed at 250r / min, stir and mix for 8 minutes, then add cyclohexane, keep the temperature and speed Continue to stir for 3 hours, add sodium hydroxide solution to adjust the pH value to 10, set the temperature to 115°C, and the rotation speed to 350r / min, and stir for 18 hours. After the reaction, wash with deionized water and absolute ethanol three times in sequence. obtain the first mixt...

Embodiment 3

[0079] A high temperature resistant composite crosslinking agent, comprising the following raw materials in parts by weight:

[0080] 30 parts of zirconium oxychloride octahydrate solution, 11 parts of sodium lauryl sulfate solution, 50 parts of cyclohexane, 20 parts of glycerol, 2 parts of borax and 4 parts of auxiliary additives;

[0081] The high temperature resistant composite crosslinking agent is prepared through the following steps:

[0082] Step 1: Add the zirconium oxychloride octahydrate solution dropwise to the sodium lauryl sulfate solution, set the temperature at 30°C and the speed at 350r / min, stir and mix for 12 minutes, then add cyclohexane, keep the temperature and speed Continue to stir for 5 hours without changing, add sodium hydroxide solution to adjust the pH value to 11, set the temperature at 125°C, and the rotation speed at 450r / min, stir and react for 22 hours, after the reaction is completed, wash with deionized water and absolute ethanol three times ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com