A new composite terminal

A composite terminal, a new type of technology, used in coupling devices, contact parts, fixed/insulated contact members, etc., can solve the problems of poor safety, weak strength, poor contact, etc., to achieve reasonable structure, long service life, and prevent overheating and deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

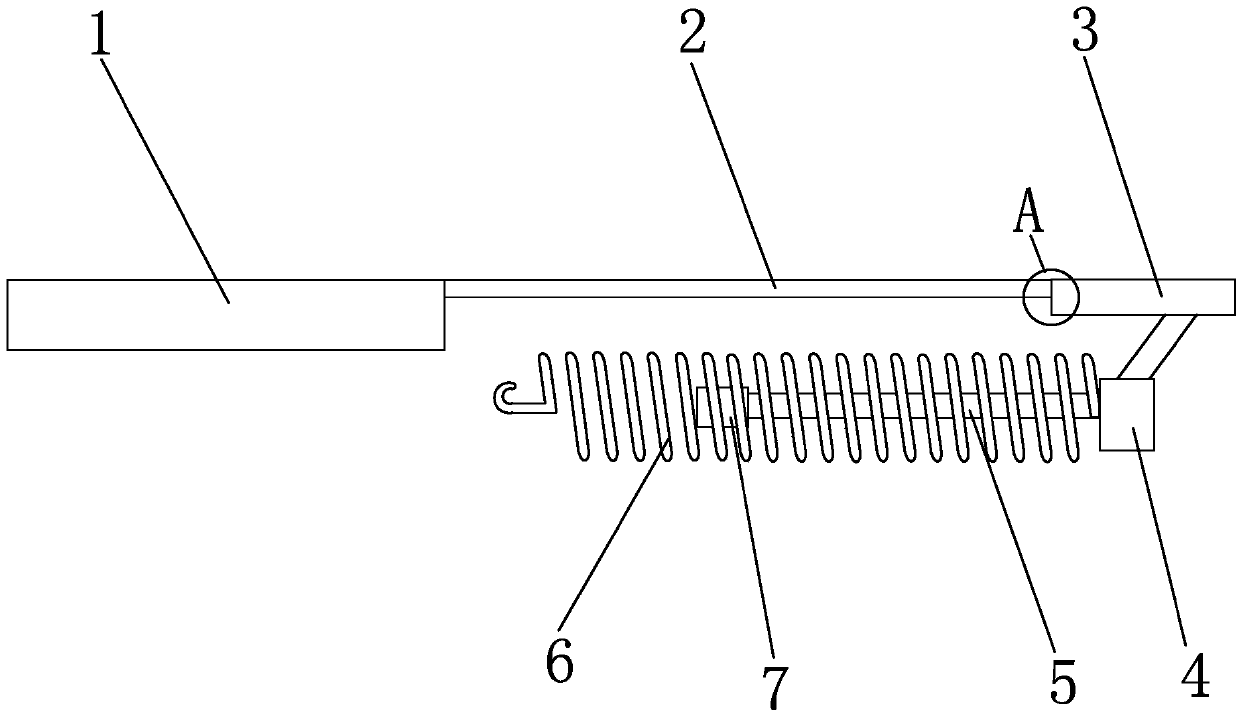

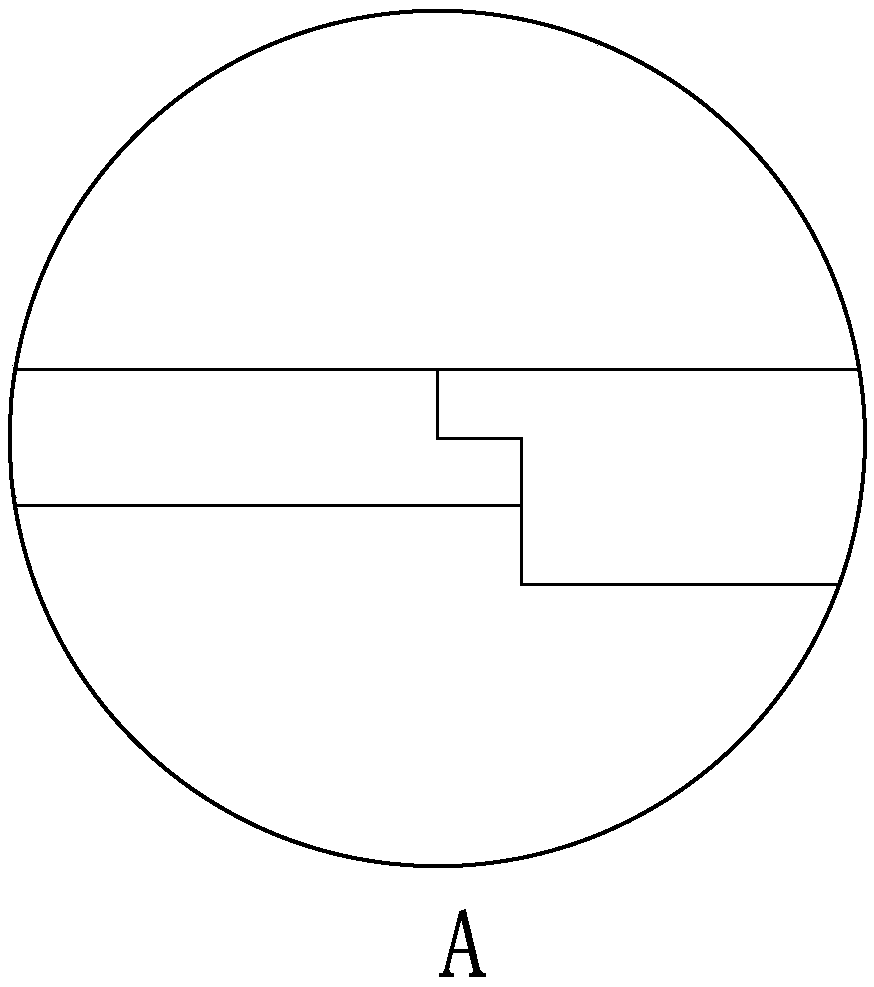

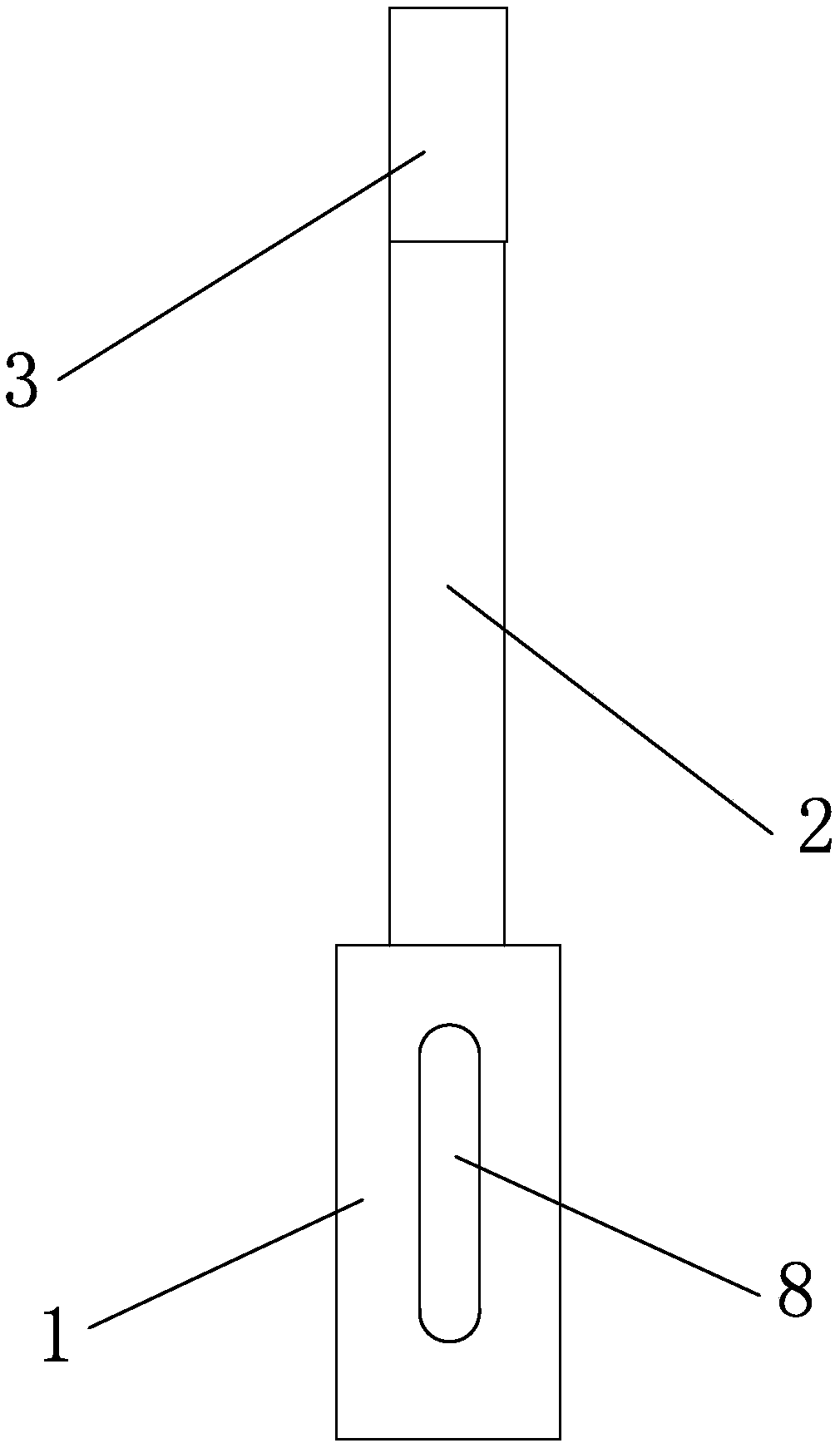

[0023] combine Figure 1 to Figure 4 , The present invention is a new composite terminal, including a terminal body, a heat-sensitive contact piece 3 , a connecting terminal 4 , and a telescopic spring 6 . The terminal body includes a tail connection section 1 and a front contact section 2 . The terminal body is in the shape of a strip plate, the tail connection section 1 is connected to the front contact section 2, and the two sides of the tail connection section 1 are arranged parallel to each other and bent at 90°. Preferably, a sliding groove 8 along the length direction of the terminal body is provided on the tail connection section 1 . The heat-sensing sheet 3 is connected to the front contact section 2, and the contact surface between the heat-sensing sheet 3 and the front contact section 2 is a stepped structure that cooperates with each other. The heat-sensitive contact piece 3 is made of nickel-chromium alloy, and the surface is coated with polytetrafluoroethylene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com