Replacement method of long-distance multi-split wire

A replacement method and multi-split technology, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of inconvenient replacement of multi-split conductors, high labor intensity, and low construction efficiency, so as to save manpower and tool investment and reduce labor intensity , Improve the effect of replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Best practice:

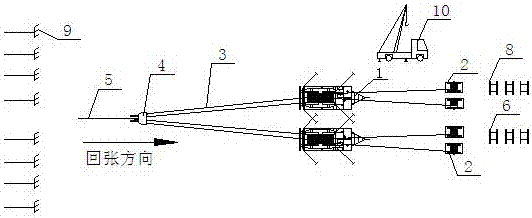

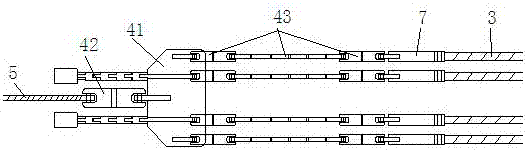

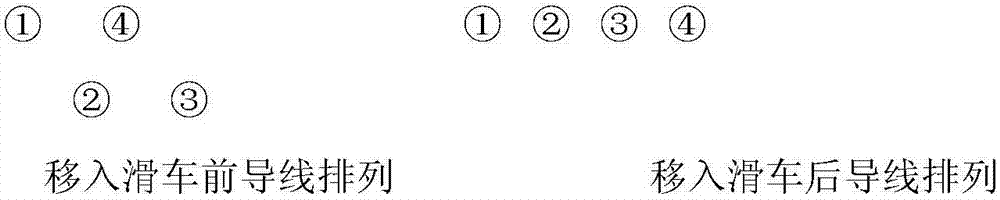

[0043] The present invention takes the example of replacing 400 old wires with four splits with 800 new wires, and proposes a long-distance multi-split wire replacement method, which is applicable to the multi-split wire replacement operation within 5km, and the operation flow is shown in the figure. The method includes steps such as construction preparation, removal of old wire attachments, suspension of the pay-off tackle and moving in of the old wire, layout of the stretching field for the old wire, recovery of the old wire, deployment of the new wire, and crimping. The specific implementation methods are as follows:

[0044] 3.1 Construction preparation

[0045] 3.1.1 Configuration of main tools

[0046] The main tensioning equipment and supporting tools are selected as follows:

[0047] (1) Calculate the braking tension and reverse pulling force of the tension machine when the old wire is recovered, and the tension of the braking tension machine an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com