Coir mat cutting device

A technology of cutting device and palm mat, which is applied in metal processing and other directions, can solve the problems of low production efficiency and low degree of automation, and achieve the effects of improving production efficiency, high degree of automation and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

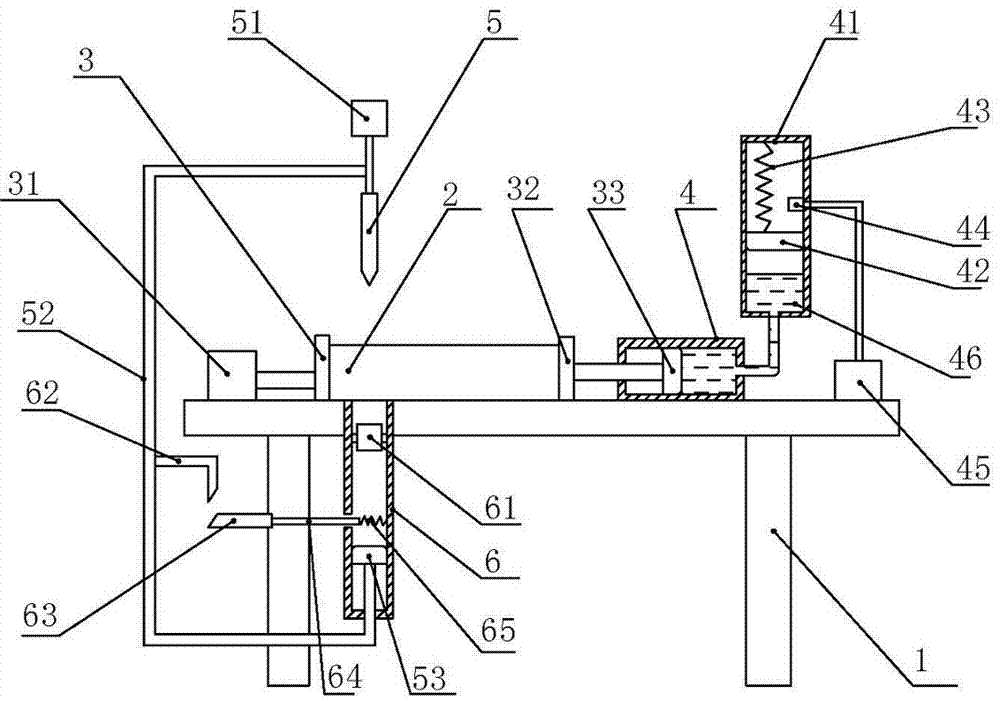

[0020] The reference numerals in the accompanying drawings of the specification include: workbench 1, brown pad 2, left splint 3, second cylinder 31, right splint 32, first piston 33, catheter 4, visible tube 41, floating block 42, First spring 43, switch 44, the third cylinder 45, water 46, cutter 5, first cylinder 51, connecting rod 52, second piston 53, air pipe 6, negative pressure vane 61, first wedge bar 62, second Wedge bar 63, electrostatic plate 64, second spring 65.

[0021] The embodiment is basically as figure 1 Shown:

[0022] A palm mat 2 cutting device of the present invention comprises a workbench 1, a guide groove (not shown in the figure) is installed on the top of the workbench 1, a cutter 5 is slidingly arranged in the guide groove, and the cutter 5 is connected to a first cylinder 51 A trachea 6 is installed below the workbench 1, and the inlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com