Oil-proof device for sewing machines

A sewing machine and oil leakage prevention technology, which is applied to sewing machine components, sewing machine casings, sewing equipment, etc., can solve the problem of difficult oil leakage and other problems, and prevent oil leakage and leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

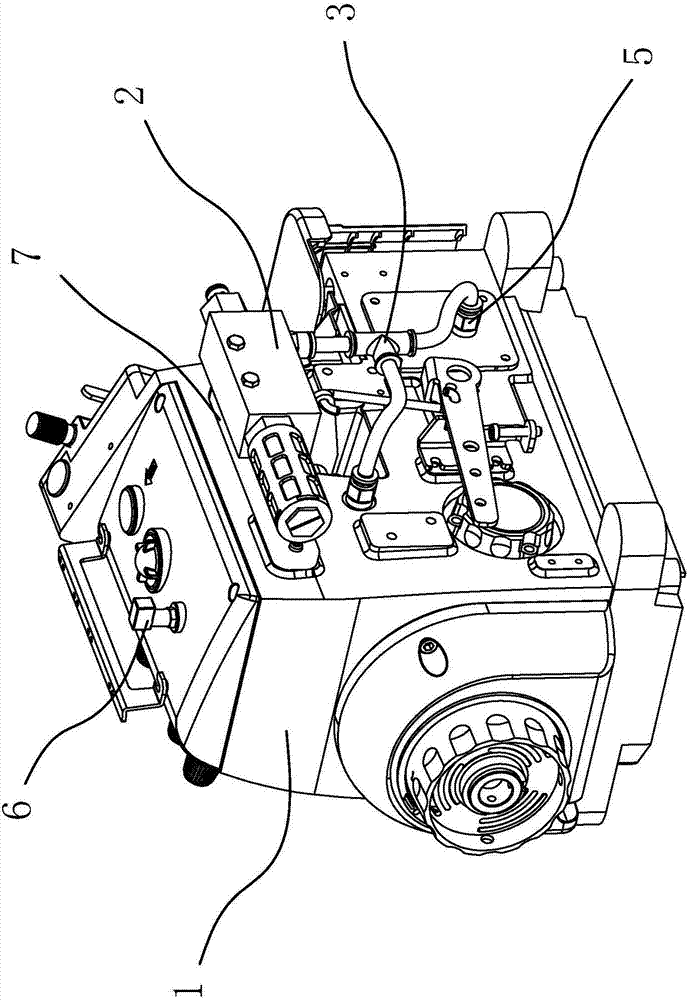

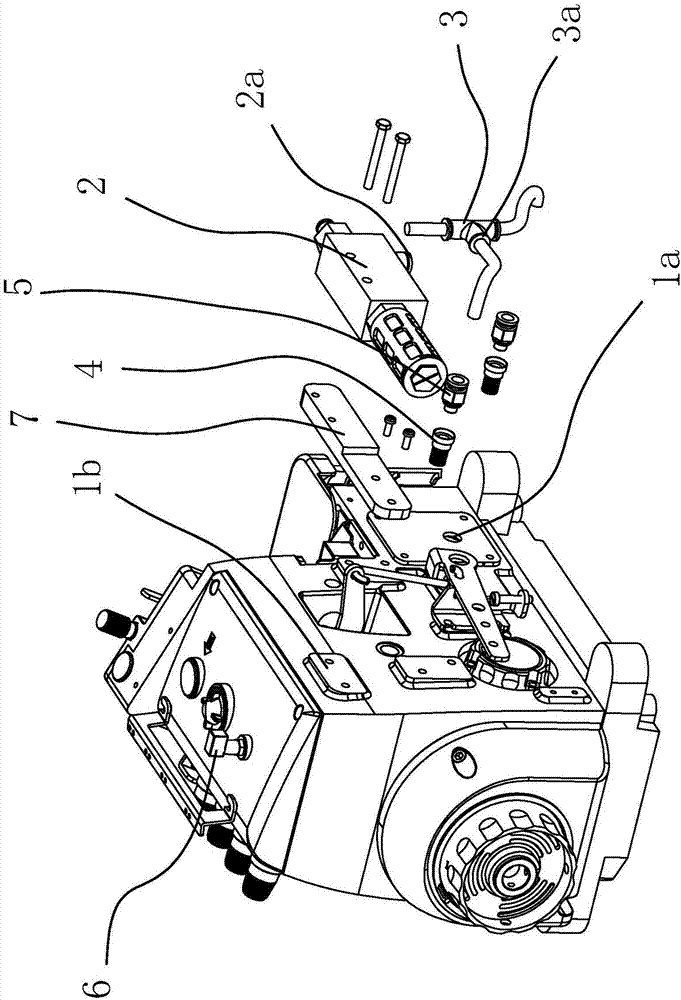

[0026] like figure 1 and 2 As shown, the sewing machine includes a casing 1, the casing 1 has an oil cavity, and the oil cavity is a closed cavity. The oil leakage prevention device includes a pressure relief member arranged on the casing 1. The pressure relief member communicates with the oil chamber and can reduce the air pressure in the oil chamber to be lower than or equal to atmospheric pressure. There is also a pressure relief member and the oil chamber. With oil filter 4.

[0027] Specifically, the pressure relief component is a negative pressure generator 2 , and the outer wall of the casing 1 has a protruding connecting boss 1b, and the negative pressure generator 2 is connected to the connecting boss 1b through a connecting bracket 7 . The connecting bracket 7 is in the shape of a strip plate, one plate surface of the connecting bracket 7 is fixed on the connecting boss 1b by screws, the other plate surface of the connecting bracket 7 has a step, the negative press...

Embodiment 2

[0031] The structure and features of this embodiment are basically the same as those of Embodiment 1, the difference is that: the casing 1 is provided with a connection port communicating with the oil chamber, the connection port is provided with a pipe joint, and a filter is provided between the pipe joint and the connection port. The oil tank, the pressure relief part is a one-way air outlet valve, and the one-way air outlet valve is connected with the pipe joint. The setting of the one-way air outlet valve makes the air inside the oil chamber of the casing 1 only flow outward in one direction, so that when the air pressure in the oil chamber of the casing 1 rises, it can automatically flow outward due to the pressure difference. Exhaust and pressure relief, so that the atmospheric pressure in the oil chamber is less than or equal to the outside world, and the oil filter on the pipe joint can filter the oil mist during the pressure relief process, preventing the oil mist from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com