Axial leading-out double-pole-plate coiling pulse formation line

A bipolar plate and pulse technology, applied in the direction of electric pulse generator circuit, energy storage element to generate pulse, etc., can solve the problems of difficult insulation, no strip line structure, weak insulation at the connection, etc., and achieve the output waveform quality Good, fast output pulse leading edge, convenient for high voltage insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

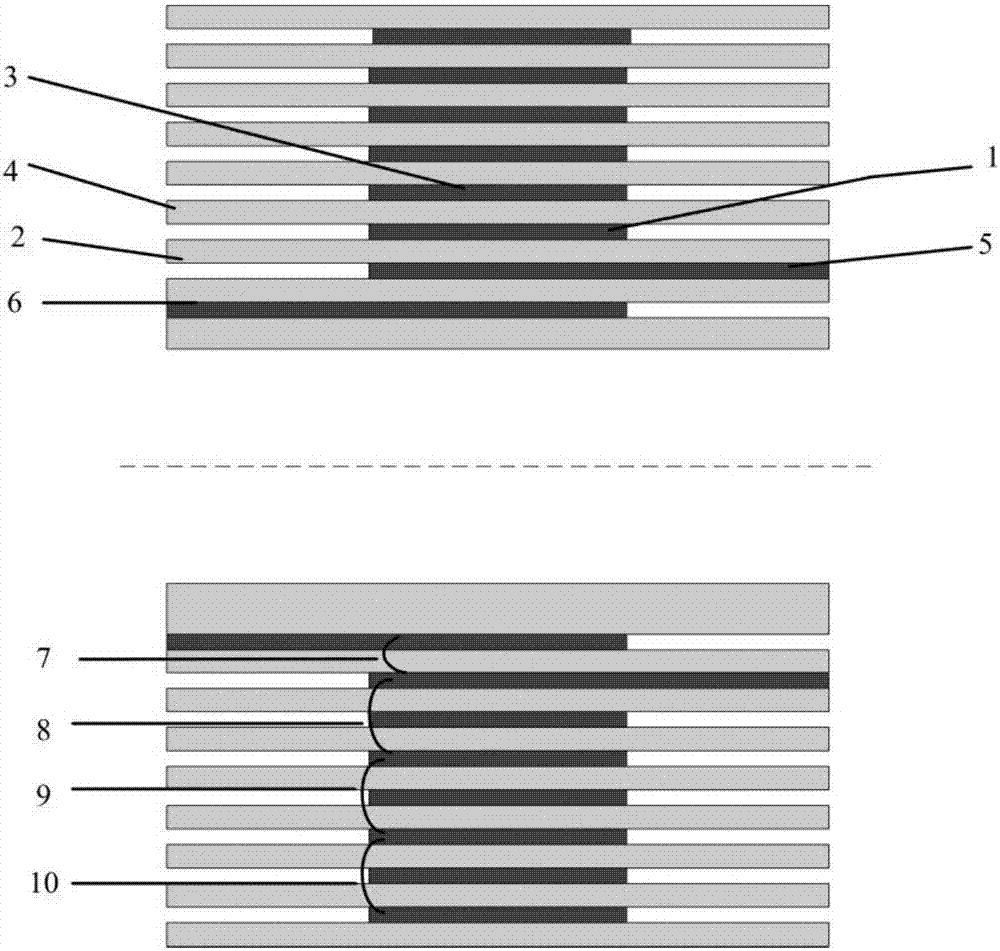

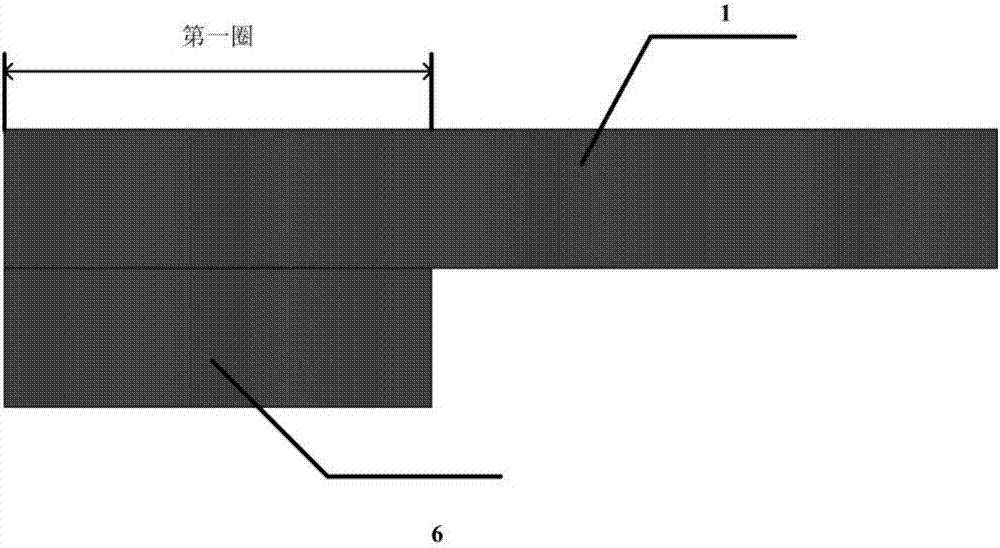

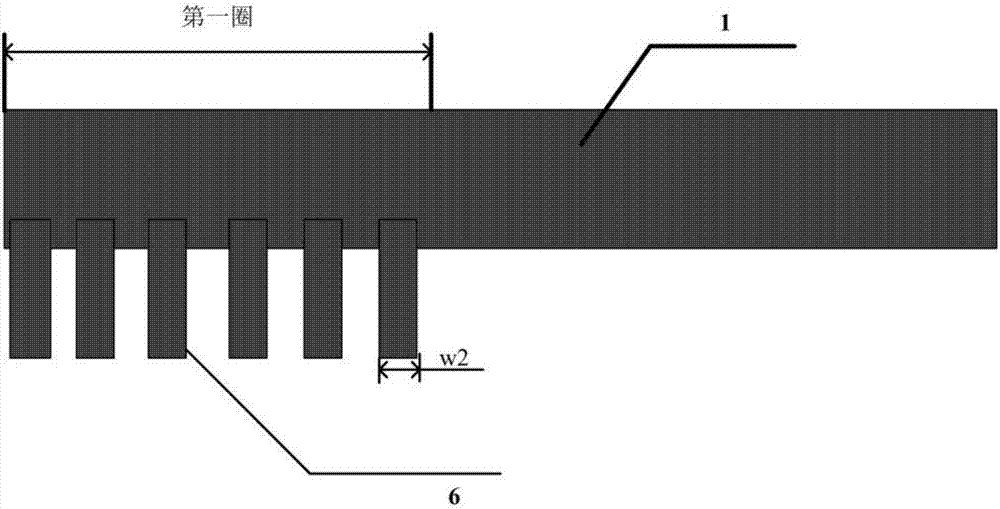

[0018] An axially drawn bipolar plate wound pulse forming line, such as figure 1 As shown, the main body is composed of two layers of polar plates and two layers of dielectric simultaneously wound in the form of an Archimedes spiral. From the inside to the outside, there are high-voltage polar plate 1, inner insulating medium 2, low-voltage polar plate 3, and outer Insulation medium 4;

[0019] The high-voltage plate 1 and the low-voltage plate 3 are metal foils with a relatively thin thickness, and their thickness is determined by the skin depth of the metal in which the pulse is formed. and the low-voltage pole plate 3 are metal foils whose thickness is greater than twice the skin depth; wherein the positions of the high-voltage pole plate 1 and the low-voltage pole plate 2 can be interchanged.

[0020] The inner insulating medium 2 and the outer insulating medium 4 have the same thickness and width, both of which are laminated by multi-layer dielectric films, and their thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com